Low-melting metal freezing printing system and method

A low-melting-point metal and printing system technology, applied in the field of metal printing, can solve the problems of slow metal solidification process, long manufacturing cycle, inability to achieve continuous work, etc., and achieve the effect of shortening the production cycle, simple manufacturing process, and recyclable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The embodiment of the present invention is described by taking 2D metal flexible circuit freeze printing as an example.

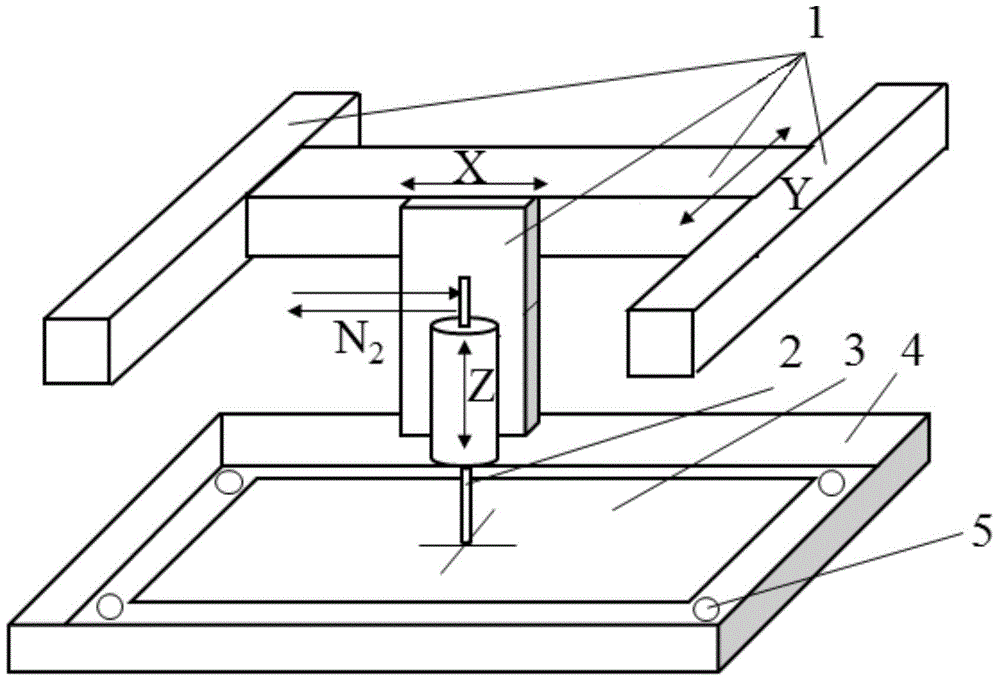

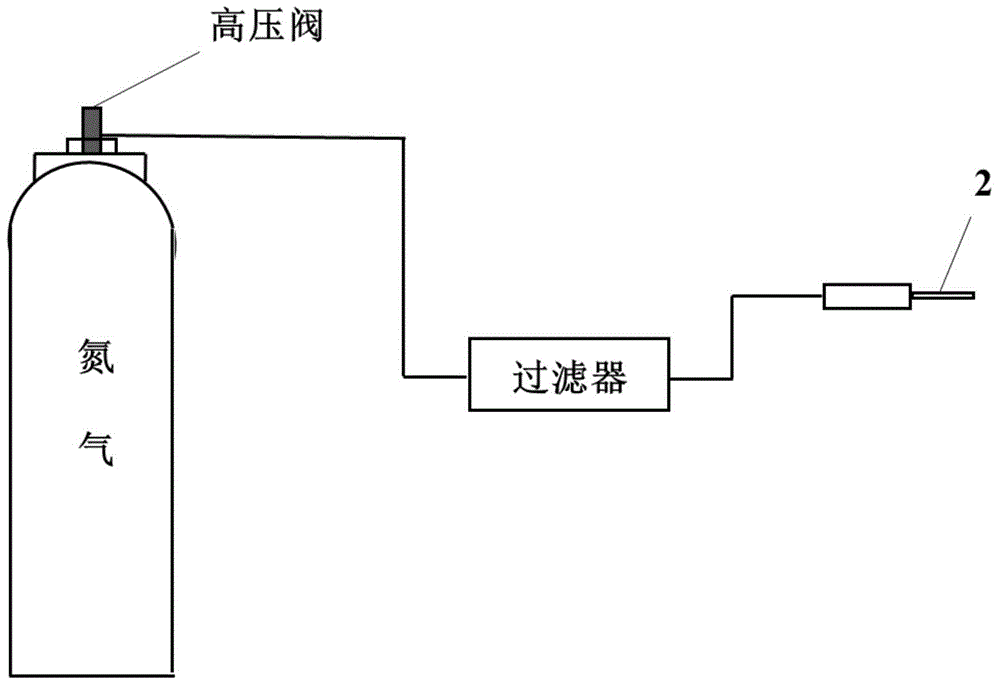

[0088] In this embodiment, the low-melting point metal freezing printing system, such as figure 1 As shown, it includes: a three-dimensional mobile platform 1 , a freezing probe 2 , a printing substrate 3 , a liquid metal pool 4 and a leaking hole 5 .

[0089] In the present embodiment, the liquid metal pool 4 is a cuboid container with a volume of 0.4L (200mm×200mm×10mm), and its material is plexiglass; the number of the leakage holes 5 is four, located in the liquid metal pool 4 The four corners are through holes with a diameter of 10mm, which can be closed or opened manually; the printing substrate 3 is placed in the center above the liquid metal pool 4, with a size of 10mm×10mm×0.5mm, and the material is PDMS (Dijia base siloxane) silica gel.

[0090] The liquid metal material is a GaIn24.5 eutectic alloy with a melting point of 15.7° C., conta...

Embodiment 2

[0101] The embodiment of the present invention is described by taking 3D metal sheet freeze printing as an example.

[0102] In this embodiment, the low-melting point metal cryoprinting system includes: a three-dimensional mobile platform 1 , a cryoprobe 2 , a liquid metal pool 4 and a leaking hole 5 , and the printing substrate 3 is not included in the system.

[0103] In the present embodiment, the liquid metal pool 4 is a cuboid container with a volume of 0.4L (200mm×100mm×20mm), and its material is plexiglass; the number of the leakage holes 5 is four, located in the liquid metal pool 4 The four corners are through holes with a diameter of 8mm, which can be closed or opened manually.

[0104] The liquid metal material is a GaIn24.5 eutectic alloy with a melting point of 15.7° C. and is stored in the liquid metal pool 4 .

[0105] The cryoprobe is a 3D probe (linear), with a structure such as Figure 4 As shown, the probe has a diameter of 2 mm and a length of 100 mm. It ...

Embodiment 3

[0115] The embodiment of the present invention is described by taking 3D metal cube freeze printing as an example.

[0116] In this embodiment, the low-melting point metal cryoprinting system is as in Embodiment 2.

[0117] In the present embodiment, the liquid metal pool 4 is a cuboid container with a volume of 0.2L (100mm×100mm×20mm), and its material is plexiglass; the number of the leakage holes 5 is four, located in the liquid metal pool 4 The four corners are through holes with a diameter of 5mm, which can be closed or opened manually.

[0118] The liquid metal material is a GaIn24.5 eutectic alloy with a melting point of 15.7° C. and is stored in the liquid metal pool 4 .

[0119] The cryoprobe is a 3D probe (rectangular) with a structure as shown in 5. The cross-sectional size of the probe is 50 mm × 50 mm (thickness 1 mm), fixed on the three-dimensional mobile platform 1, and the cross-section is parallel to the plane where the liquid metal pool is located. Realize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com