Semi-hydrated-two-hydrated wet process phosphoric acid production process and system thereof

A wet-process phosphoric acid and production process technology, applied in the field of phosphoric acid production process and its system, can solve the problems of wastewater discharge polluting the environment, small-scale equipment, high energy consumption, etc., and achieve environmental friendliness, low equipment investment and operating costs, and energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

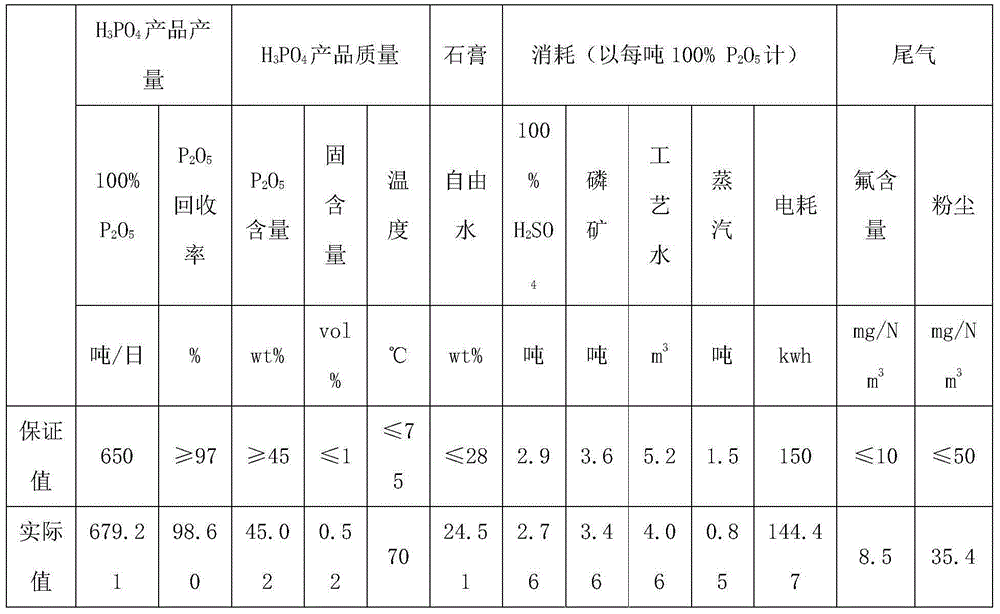

Examples

Embodiment Construction

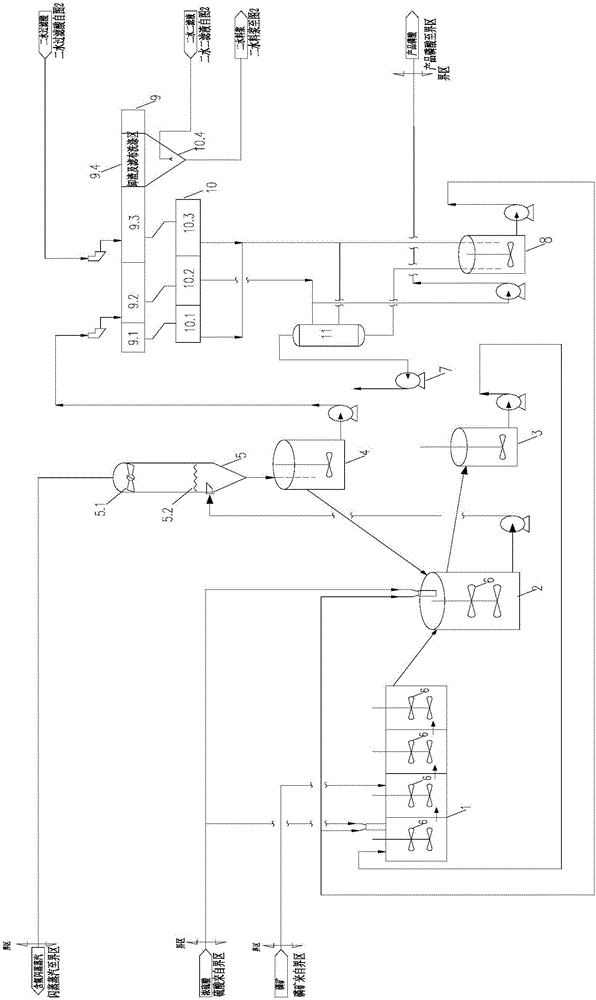

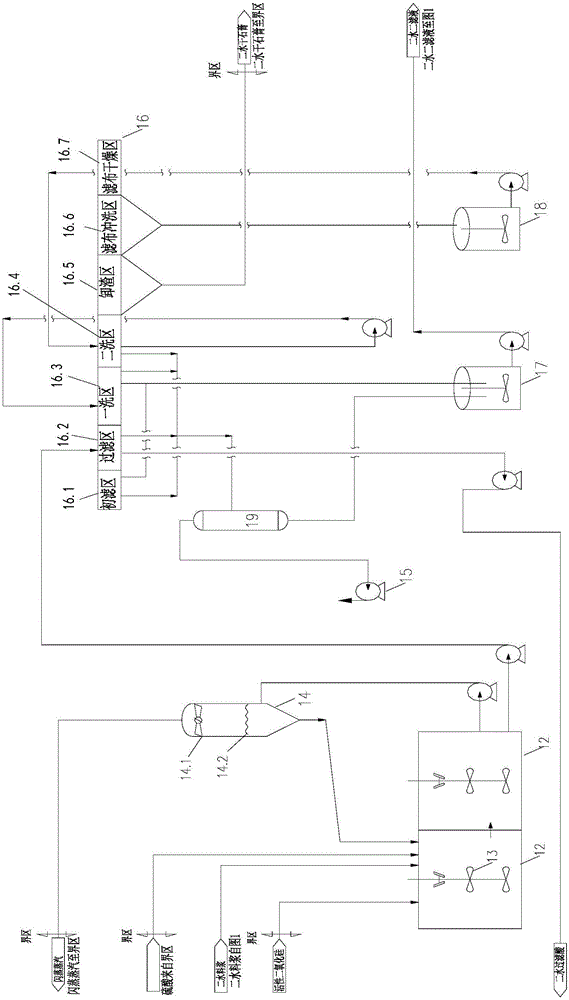

[0040] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

[0041] The system of the present invention comprises water reaction and filter system and dihydric reaction and filter system,

[0042] Described semi-aqueous reaction and filter system comprise that be provided with stirrer 6 dissolving tanks 1 (the present embodiment is 4 in series), crystallization tank 2, the first high position flash cooler 5, filter feeding tank 4, that are connected successively Semi-water filter 9 (for the rotary table filter) and the lower air tray 10, the outlet of the crystallization tank 2 is also connected to the dissolution tank 1 through the aging tank 3, and the semi-water filter 9 is provided with an initial stage from front to back. Filtering area 9.1, filtering area 9.2, first washing area 9.3 and filter cloth washing area 9.4, the lower air disc 10 is provided with the primary filtering area 9.1, filtering area 9.2, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com