Potted anthurium coated controlled-release fertilizer and preparation method thereof

A technology of controlled-release fertilizer and anthurium, applied in layered/coated fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of low fertilizer input cost, nutrient leaching, unsustainable development, etc., to reduce labor input, The effect of ensuring nutritional needs and promoting the growth of anthurium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

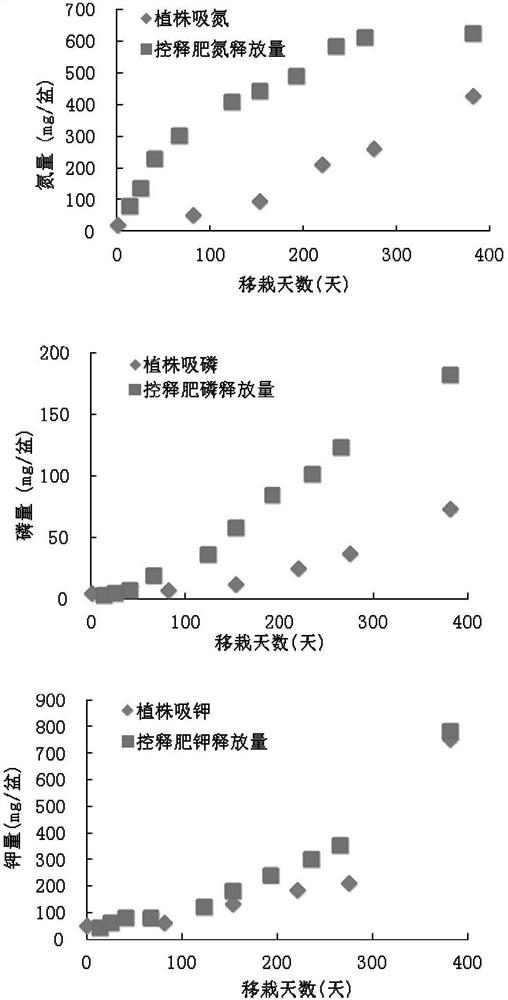

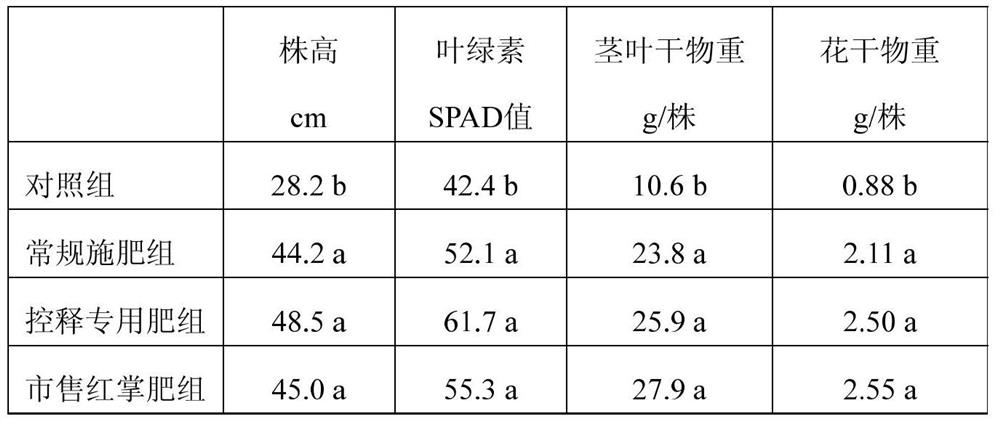

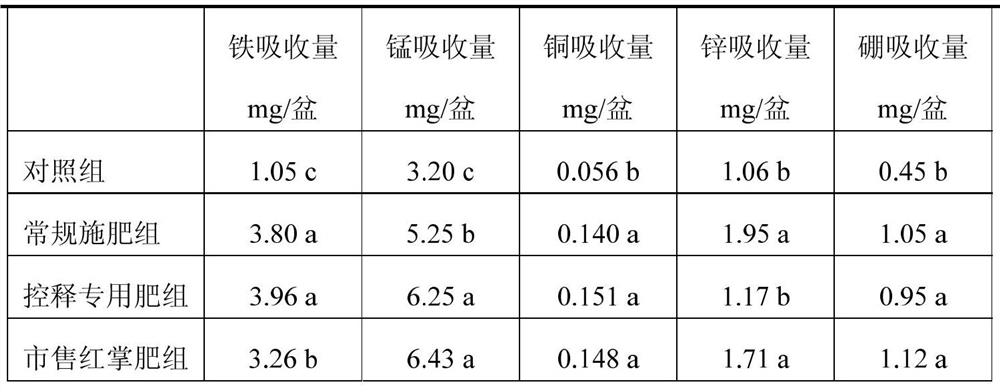

[0059] Example 1, preparation of special fertilizer for potted red controlled release and its application effect test

[0060] (1) Preparation of L-type controlled-release compound fertilizer

[0061] The fertilizer is produced by a small test spouted bed coating equipment. With 20g regenerated polypropylene (purchased by the market) and 20g multifactor fertilizer (No. 2 Kangpei produced by Holland Akzo Nobel (China) Co., Ltd., iron content is 4.0%, zinc content is 1.5%, copper content is 1.5% , the manganese content is 4.0%, the magnesium content is 5.4%, the boron content is 0.5%, the molybdenum content is 1.0%;) is dissolved in the turpentine oil (130 ℃-140 ℃ all can) of 1L heating and stirs the solution with the stirrer, then passes through Add 1kg of Batian compound fertilizer (produced by Shenzhen Batian Ecological Engineering Co., Ltd., the content of nitrogen, phosphorus and potassium is 15-5-20, and the diameter is 2-3mm) into the coating tower, blown in by a blower ...

Embodiment 2

[0086] Example 2, preparation of special fertilizer for potted red controlled release and its application effect test

[0087] (1) Preparation of L-type controlled-release compound fertilizer

[0088] The fertilizer is produced by a small test spouted bed coating equipment. With 21g regenerated polypropylene (purchased by the market) and 20g multifactor fertilizer (No. 2 of Kangpei produced by Holland Akzo Nobel (China) Co., Ltd., iron content is 4.0%, zinc content is 1.5%, copper content is 1.5% , the manganese content is 4.0%, the magnesium content is 5.4%, the boron content is 0.5%, the molybdenum content is 1.0%;) is dissolved in the turpentine oil (130 ℃-140 ℃ all can) of 1L heating and stirs the solution with the stirrer, then passes through Add 1kg of Batian compound fertilizer (produced by Shenzhen Batian Ecological Engineering Co., Ltd., the content of nitrogen, phosphorus and potassium is 15-5-20, and the diameter is 3-4mm) into the coating tower, blown in by a blow...

Embodiment 3

[0103] Example 3, preparation of special fertilizer for potted red controlled release and its application effect test

[0104] (1) Preparation of L-type controlled-release compound fertilizer

[0105] The fertilizer is produced by a small test spouted bed coating equipment. With 22g recycled polypropylene (purchased by the market) and 20g multivariate fertilizer (No. 2 of Kangpei produced by Holland Akzo Nobel (China) Co., Ltd., iron content is 4.0%, zinc content is 1.5%, copper content is 1.5% , the manganese content is 4.0%, the magnesium content is 5.4%, the boron content is 0.5%, the molybdenum content is 1.0%;) is dissolved in the turpentine oil (130 ℃-140 ℃ all can) of 1L heating and stirs the solution with the stirrer, then passes through Add 1kg of Batian compound fertilizer (produced by Shenzhen Batian Ecological Engineering Co., Ltd., the content of nitrogen, phosphorus and potassium is 15-5-20, and the diameter is 1-2mm) into the coating tower, blown in by a blower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com