Special polishing liquid suitable for gallium oxide substrate polishing and preparation method thereof

A substrate substrate, gallium oxide technology, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of strong acid and alkali resistance, no cleavage properties, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Dissolve 1 mass part of disodium edetate, 1.5 mass parts of sodium hydroxide and 1 mass part of triethanolamine in 47 mass parts of deionized water. After sodium oxide and triethanolamine are fully dissolved, then the octylphenol polyoxyethylene ether (10) of 0.5 mass parts and the defoamer of 0.1 mass parts are also dissolved in described deionized water, treat described surfactant and defoamer After the foaming agent was fully dissolved, the obtained mixed solution was slowly added dropwise to 50 parts by mass of the silica sol emulsion which was constantly being stirred, so as to prepare the polishing solution of the present invention.

[0052] The particle size of silicon dioxide in the silica sol emulsion is 15nm, and the mass concentration of silicon dioxide is 40%.

Embodiment 2

[0054] First, 1 mass part of tetrasodium edetate, 0.5 mass part of sodium hydroxide and 1 mass part of triethanolamine are dissolved in 47.5 mass parts of deionized water, and the disodium edetate, hydrogen After sodium oxide and triethanolamine are fully dissolved, then the octylphenol polyoxyethylene ether (10) of 0.5 mass parts and the defoamer of 0.1 mass parts are also dissolved in described deionized water, treat described surfactant and defoamer After the foaming agent was fully dissolved, the obtained mixed solution was slowly added dropwise to 50 parts by mass of the silica sol emulsion which was constantly being stirred, so as to prepare the polishing solution of the present invention.

[0055] The particle size of silicon dioxide in the silica sol emulsion is 15nm, and the mass concentration of silicon dioxide is 40%.

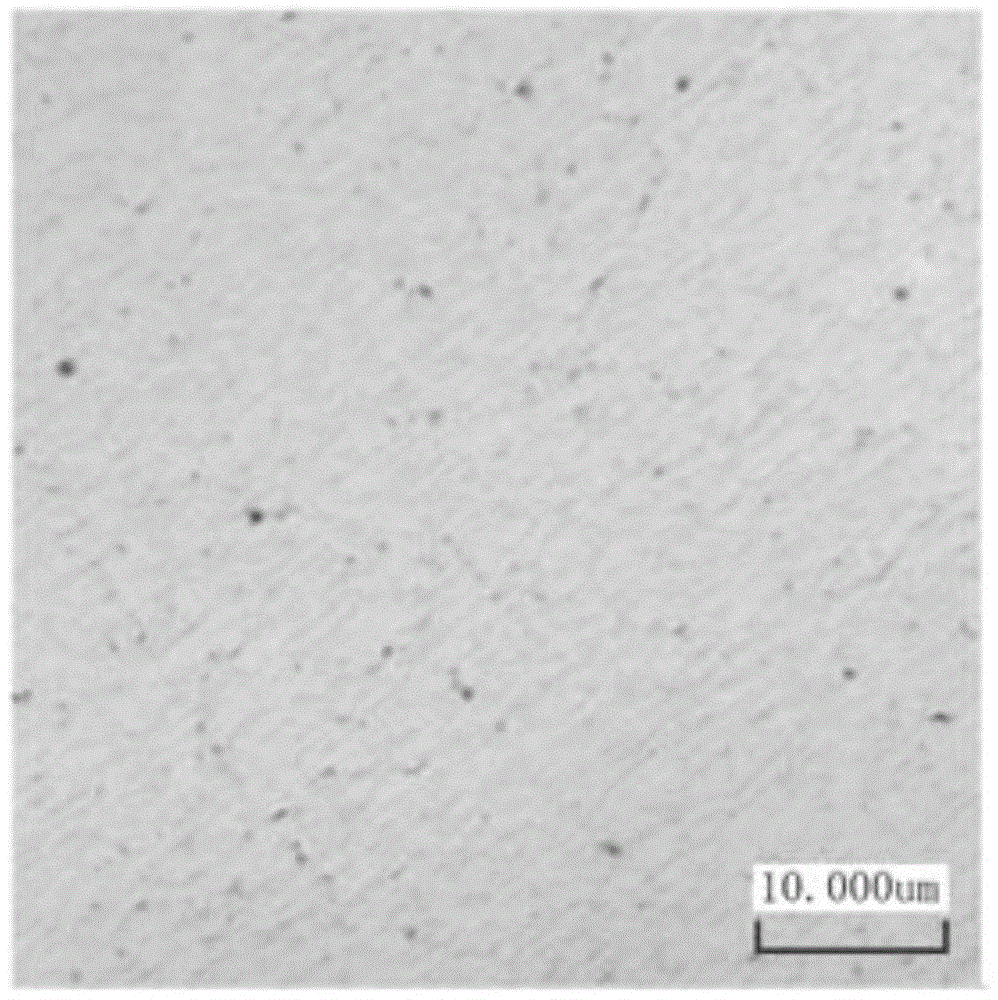

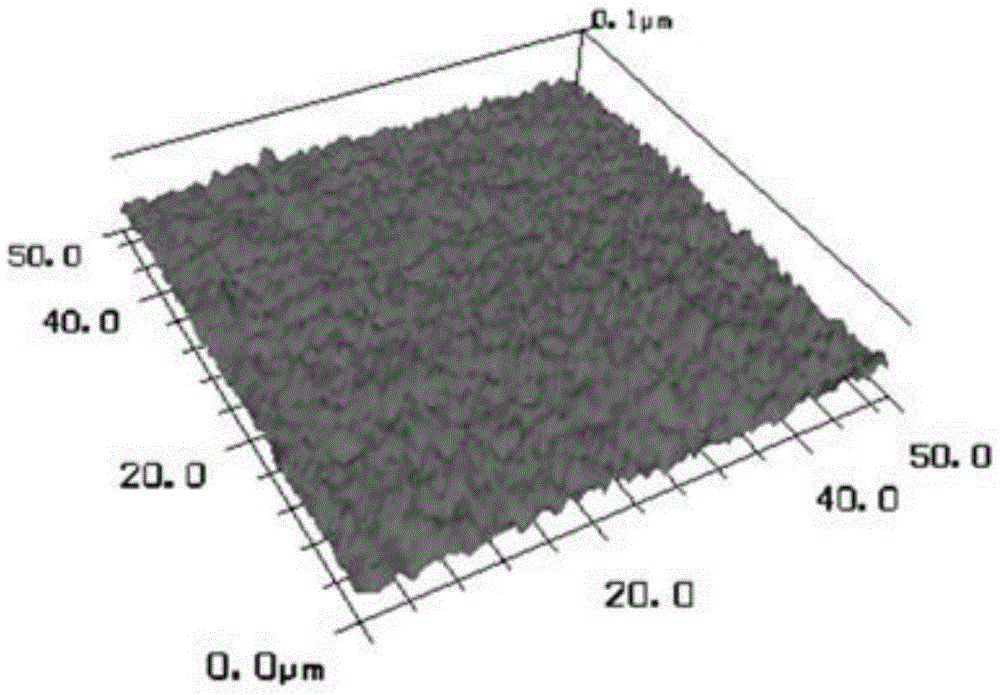

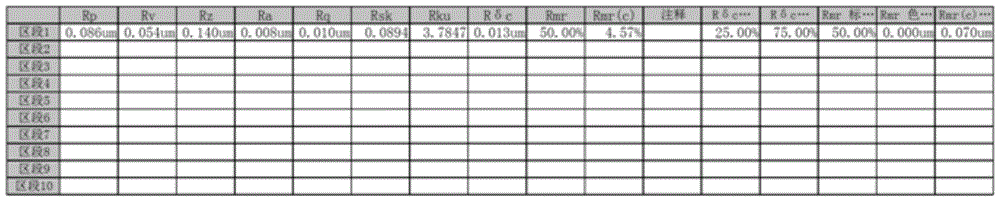

[0056] Using the polishing solution obtained in the above-mentioned preferred embodiment 1 and preferred embodiment 2 to carry out chemical mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com