A kind of lanthanum manganate/semiconductor metal oxide composite gas sensitive material and preparation method thereof

A gas-sensitive material and semiconductor technology, applied in the direction of material resistance, etc., can solve the problems of gas-sensitive materials that have not yet appeared, and achieve the effect of being conducive to large-scale industrial use, good gas-sensing performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh an appropriate amount of La(NO 3 ) 3 ·6H 2 O and Mn(NO 3 ) 2 4H 2 O, dissolved in distilled water, and press citric acid: metal ion (La 3+ and Mn 2+ )=0.25 Weighed a certain amount of citric acid and added it to the above solution, and stirred at room temperature for 24 hours to obtain the LMO precursor solution.

[0026] Nano SnO to be purchased 2 Add ethanol to the particle powder and ultrasonically vibrate for 15 minutes, dry it, and calculate the volume of LMO precursor solution that needs to be added in advance, so that LMO occupies the nanometer SnO 2 0.5wt% of the particle powder mass; to nano SnO 2 Add quantitative LMO precursor solution and appropriate amount of water to the particle powder, and grind to obtain LMO / SnO 2 slurry.

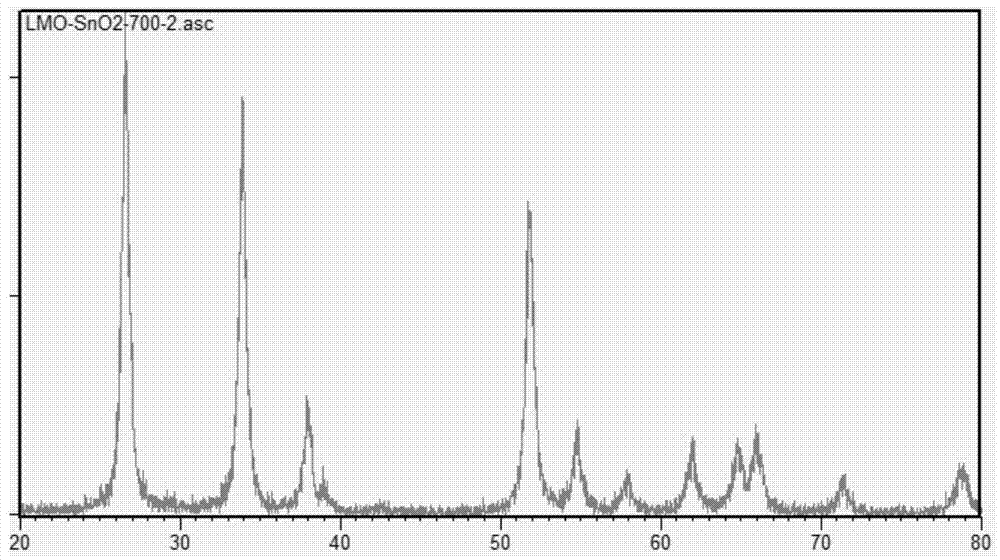

[0027] figure 1 for LMO / SnO 2 The XRD pattern of the composite gas-sensing material powder obtained after the slurry was calcined at 700°C / 2h, SnO can be seen in the figure 2 The powder is in the rutile phase, while...

Embodiment 2

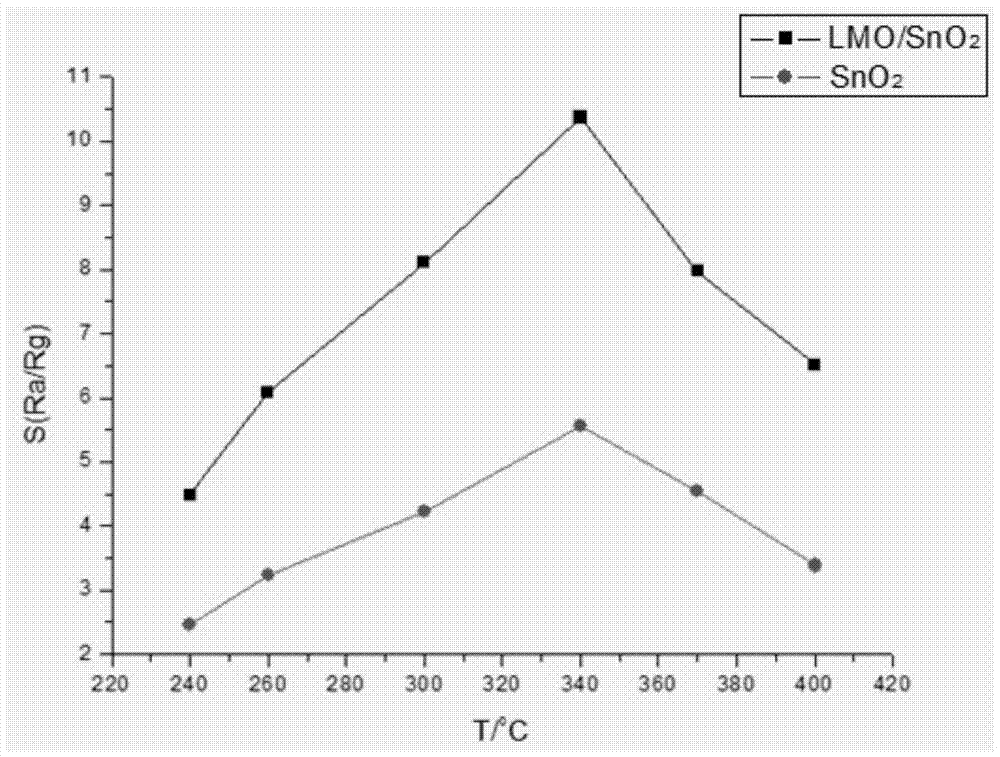

[0031] The steps are as in Example 1, the mass percentage of LMO is increased from 0.5wt% to 2%, and the prepared LMO / SnO 2 The sensitivity of the sensor to 100ppm hydrogen reaches the highest at 340°C, which is 10.1; while pure SnO 2 The sensitivity of the sensor to 100ppm hydrogen at 340°C is 5.5, an improvement of 83%.

Embodiment 3

[0033] Weigh an appropriate amount of La(NO 3 ) 3 ·6H 2 O and Mn(NO 3 ) 2 4H 2 O, dissolved in distilled water, and press citric acid: metal ion (La 3+ and Mn 2+ )=0.25 A certain amount of citric acid was weighed and added to the above solution, and stirred at room temperature for 24 hours to obtain the LMO precursor solution.

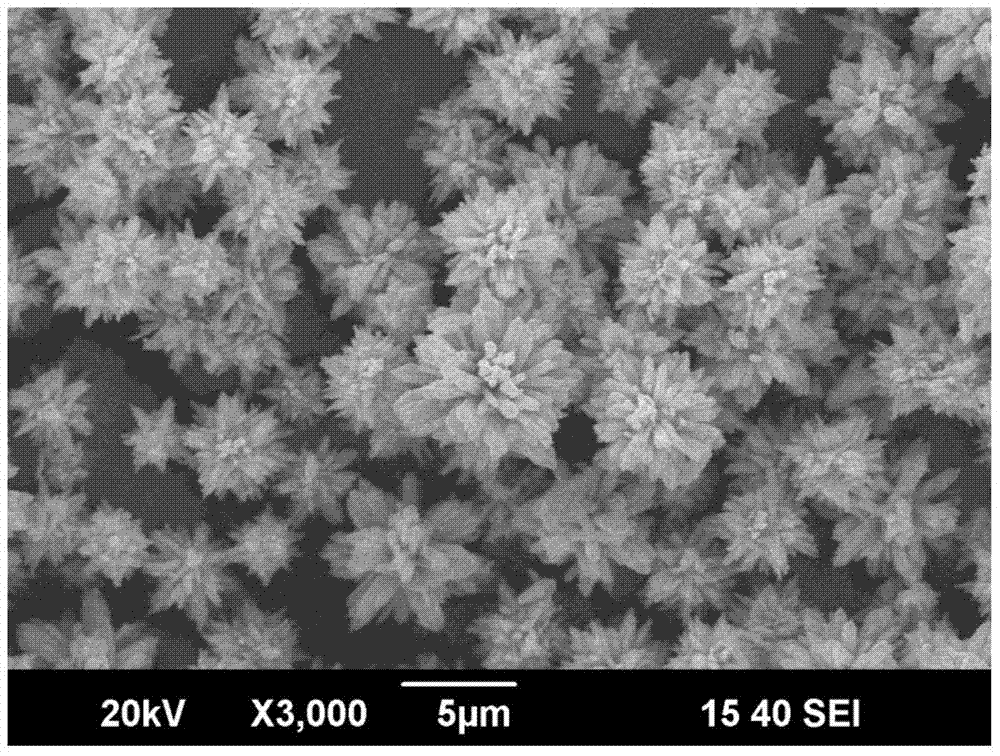

[0034] Weigh 1.1962g C 4 h 6 o 4 Zn·2H 2O, dissolved in 85mL distilled water, stirred for 10min to make the solution completely clear; slowly pour 35mL 2M NaOH solution into the above solution, the mixed solution will appear cloudy first and then clear; pour the above mixed solution into 100mL polytetrafluoroethylene In an ethylene reactor, the filling amount is 80%, and it is kept in an oven at 200° C. for 20 hours; the white powder obtained after the heat preservation is washed three times with water and alcohol, and centrifuged to obtain a white ZnO powder. The ZnO powder has a nanoflower structure, image 3 It is the SEM picture of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com