Method for testing content of aluminum oxide in aluminum metaphosphate

A technology of aluminum metaphosphate and testing method, which is applied in the direction of chemical analysis by titration method, can solve the problems affecting the accuracy of test results, the types and amounts of reagents used are large, and the analysis process is complicated, so as to achieve the advantages of popularization and utilization, high accuracy High and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Weigh 0.2g (accurate to 0.0001g) of the sample dried at 105°C into a beaker, add 10mL of 100g / L sodium hydroxide solution until the sample is completely dissolved; add 10mL of 6mol / L hydrochloric acid until the solution becomes acidic;

[0045] 2) Add 20mL of 0.05mol / L disodium edetate standard solution, add 2 drops of phenolphthalein, neutralize it with ammonia water to red, then adjust it to colorless with hydrochloric acid and add one drop in excess; add 10mL of 60% ammonium acetate, heat and boil for 3min Take it off, add 2 drops of xylenol orange solution, and titrate with zinc sulfate standard solution to red;

[0046] 3) Add 30mL of 50g / L sodium fluoride solution, heat and boil for 3min to take it off, and then titrate with zinc sulfate standard solution to red as the end point;

[0047] 4) Result calculation

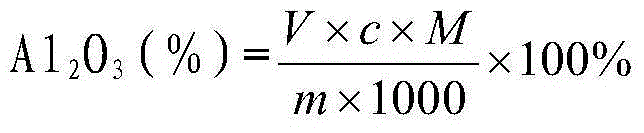

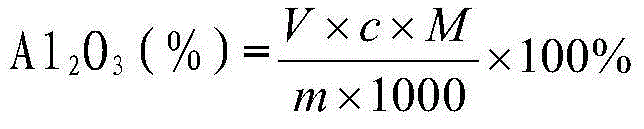

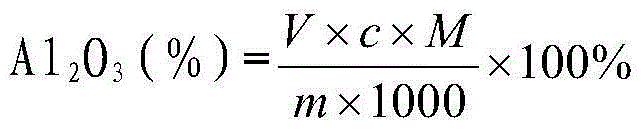

[0048] Al 2 O 3 ( % ) ...

Embodiment 2

[0055] 1) Weigh 0.3g (accurate to 0.0001g) of the sample dried at 105°C into a beaker, add 15mL of 100g / L sodium hydroxide solution until the sample is completely dissolved; add 15mL of 6mol / L hydrochloric acid until the solution becomes acidic;

[0056] 2) Add 30mL of 0.05mol / L disodium edetate standard solution, add 2 drops of phenolphthalein, neutralize it with ammonia water to red, then adjust it to colorless with hydrochloric acid and add one drop in excess; add 15mL of 60% ammonium acetate, heat and boil for 3min Take it off, add 3 drops of xylenol orange solution, and titrate with zinc sulfate standard solution to red;

[0057] 3) Add 35mL of 50g / L sodium fluoride solution, heat and boil for 4min to remove, then titrate with zinc sulfate standard solution to red as the end point;

[0058] 4) Result calculation

[0059] Al 2 O 3 ( % ) = ...

Embodiment 3

[0066] 1) Weigh 0.4g (accurate to 0.0001g) of the sample dried at 110°C into a 250mL beaker, add 20mL of 100g / L sodium hydroxide solution until the sample is completely dissolved; add 20mL of 6mol / L hydrochloric acid until the solution becomes acidic;

[0067] 2) Add 40mL of 0.05mol / L disodium edetate standard solution, add 3 drops of phenolphthalein, neutralize it with ammonia water to red, then adjust it to colorless with hydrochloric acid and add one drop in excess; add 20mL of 60% ammonium acetate, heat and boil for 5min Take it off, add 2 drops of xylenol orange solution, and titrate with zinc sulfate standard solution to red;

[0068] 3) Add 40mL of 50g / L sodium fluoride solution, heat and boil for 5min to take it off, and then titrate with zinc sulfate standard solution to red as the end point;

[0069] 4) Result calculation

[0070] Al 2 O 3 ( % ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com