Preparation method of novel light break-through IGBT device

A punch-through device technology, which is applied in the field of preparation of new light punch-through IGBT devices, can solve the problems of easily damaged IGBT devices, increased internal saturation current, and small short-circuit safe working area, so as to avoid large current impact, increase resistance value, The effect of ensuring the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

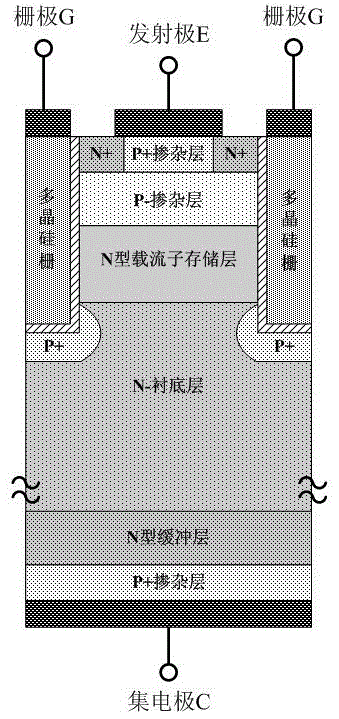

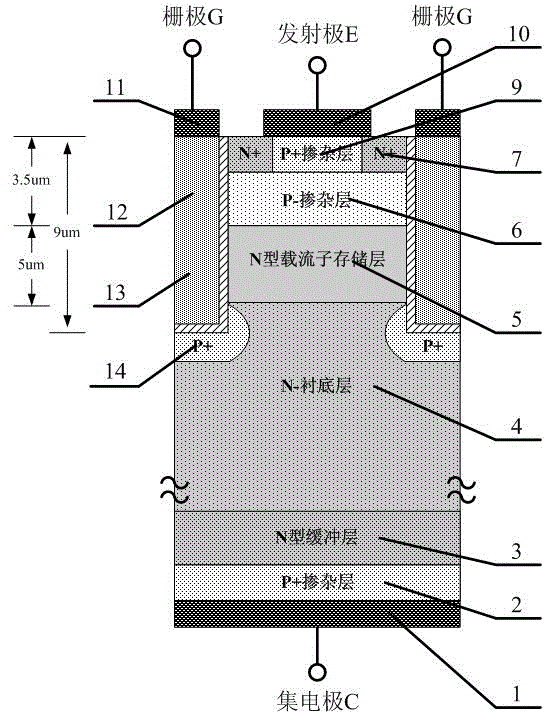

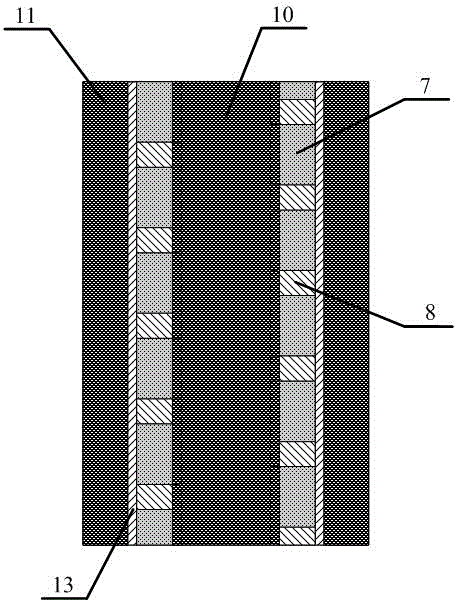

[0031] Embodiment one, figure 2 A schematic diagram of a cell section of the novel light punch-through IGBT device provided in this embodiment is shown, image 3 A schematic plan view of the cell plane of the novel light punch-through IGBT device provided in this embodiment is shown. The new light punch-through IGBT device includes several cells in a parallel structure, the lower surface of the cells is connected to the collector, and the collector metal contact layer 1, the first P+ doped layer 2, N type buffer layer 3 and N-substrate layer 4; the upper surface of the cell is respectively connected to the emitter and the gate, and the emitter metal contact layer 10 and the second P+ doped layer 9 are sequentially arranged below the emitter , a P-doped layer 6 and an N-type carrier storage layer 5, a gate metal contact layer 11, a trench gate structure composed of a polysilicon gate 12 and a gate oxide layer 13, and P+ type floating layer 14; the emitter metal contact layer...

Embodiment 2

[0038] Embodiment two, Figure 4 It shows the flow chart of the preparation method of the novel light punch-through IGBT device provided in this embodiment, Figure 5 It shows a schematic diagram of the cross section of the IGBT device shown in step S101 in the preparation method provided in this embodiment, Figure 6 It shows a schematic diagram of the cross section of the IGBT device shown in step S102 in the preparation method provided in this embodiment, Figure 7 It shows a schematic diagram of the section of the IGBT device shown in step S103 in the preparation method provided in this embodiment, Figure 8 It shows a schematic diagram of the section of the IGBT device shown in step S104 in the preparation method provided in this embodiment, Figure 9 It shows a schematic diagram of the section of the IGBT device shown in step S105 in the preparation method provided in this embodiment, Figure 10 It shows a schematic diagram of the cross section of the IGBT device show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com