Admixture capable of enhancing high-temperature properties of asphalt concrete and preparation method thereof

A technology for asphalt concrete and high temperature performance, which is applied in the field of admixtures that can improve the high temperature performance of asphalt concrete and its preparation field, can solve the problems of limited promotion and application, poor heat aging resistance, etc., and achieves simple process and improved flame retardancy. , The effect of improving low temperature cracking performance and water stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An external admixture that can improve the high-temperature performance of asphalt concrete. The chemical composition is: homopolymer PP (T30S) 10wt%, maleic anhydride 0.01wt%, dicumyl peroxide 0.03wt%, tetrakis[β-(3, 5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.03wt%, ethyl acetate 0.05wt%, polyethylene resin 90wt%. The preparation method is as follows:

[0026] (1) Dry the homopolymer PP (T30S) at 50°C for 24 hours, and set aside;

[0027] (2) According to mass percentage: homopolymer PP (T30S) 10wt%, maleic anhydride 0.01wt%, dicumyl peroxide 0.03wt%, tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester 0.03wt%, ethyl acetate 0.05wt%, matching raw material, under room temperature, carry out mixing in high-speed mixer, and wherein stirring speed is 3000r / min, and stirring time is 10~15min, obtains high molecular compatibilizer;

[0028] (3) The polymer compatibilizer and polyethylene resin are blended and ...

Embodiment 2

[0032] An external admixture that can improve the high-temperature performance of asphalt concrete. The chemical composition is: homopolymer PP (T30S) 20wt%, maleic anhydride 0.02wt%, dicumyl peroxide 0.06wt%, tetrakis[β-(3, 5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 0.06wt%, ethyl acetate 0.1wt%, polyethylene resin and high-density polyethylene resin composite material 80wt%. The preparation method is as follows:

[0033] (1) Dry the homopolymer PP (T30S) at 60°C for 24 hours and set aside;

[0034] (2) According to mass percentage: homopolymer PP (T30S) 20wt%, maleic anhydride 0.02wt%, dicumyl peroxide 0.06wt%, tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester 0.06wt%, ethyl acetate 0.1wt%, matching raw material, under room temperature, carry out mixing in high-speed mixer, and wherein stirring speed is 4000r / min, and stirring time is 10~15min, obtains high molecular compatibilizer;

[0035] (3) The polymer co...

Embodiment 3

[0039] An external admixture that can improve the high-temperature performance of asphalt concrete. The chemical composition is: homopolymer PP (S1003) 10wt%, maleic anhydride 0.01wt%, dicumyl peroxide 0.03wt%, tetrakis[β-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.03wt%, ethyl acetate 0.05wt%, polyethylene resin, linear polyethylene and low-density polyethylene composite material 90wt%. The preparation method is as follows:

[0040] (1) Dry the homopolymer PP (S1003) at 60°C for 24 hours, and set aside;

[0041] (2) According to mass percentage: homopolymer PP (S1003) 10wt%, maleic anhydride 0.01wt%, dicumyl peroxide 0.03wt%, tetrakis[β-(3,5-di-tert-butyl-4- Hydroxyphenyl) propionic acid] pentaerythritol ester 0.03wt%, ethyl acetate 0.05wt%, matching raw material, under room temperature, carry out mixing in high-speed mixer, wherein stirring speed is 3500r / min, and stirring time is 10~15min, obtains high molecular compatibilizer;

[0042] (3) T...

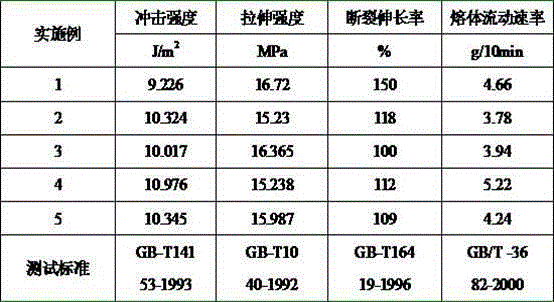

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com