Water-boiling-resistant polyester resin and preparation method thereof

A technology of polyester resin and water boiling resistance, applied in the field of polyester resin, can solve the problems of improving the wear resistance of polyester resin, achieve excellent wear resistance and durability, reasonable process design, and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

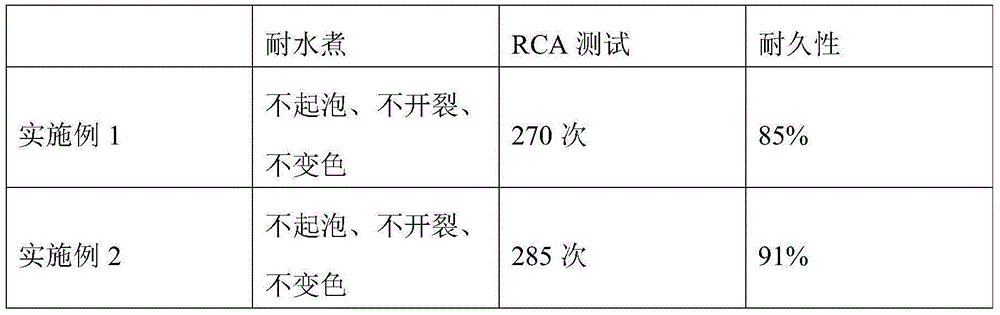

Examples

Embodiment 1

[0019] Add 400.6g of methylpropanediol, 450.7g of 1,4-butanediol and 272.8g of trimethylolpropane into a reaction kettle with a stirrer and a temperature-rising reflux device, stir and feed nitrogen, and raise the temperature to 60-80°C to The material melts to a liquid state. 456.2 g of phthalic anhydride, 734.8 g of isophthalic acid, 364.9 g of adipic acid, 170 g of UH-CARB50, and 2.5 g of monobutyltin oxide were added. Under the protection of nitrogen, the temperature is raised to effluent, the temperature of the distillation head is 90-103°C, and the temperature of the distillation head is raised to the highest reaction temperature of 220°C, the acid value of the resin is sampled and tested: 4.2mgKOH / g, when the cone-plate viscosity is 10.9P at 175°C, stop After reaction, the temperature was rapidly lowered to 90°C and the material was discharged to obtain the target water-resistant polyester resin. The alkyd feed ratio is 1.15:1.

[0020] The boiling-resistant polyester...

Embodiment 2

[0022] Add 262.5g of ethylene glycol, 507.4g of 1,6-hexanediol and 639.2g of pentaerythritol into a reaction kettle with a stirrer and a temperature-rising reflux device, stir and pass in nitrogen, and raise the temperature to 60-80°C until the material melts into a liquid state . 412 g of phthalic anhydride, 778 g of isophthalic acid, 700 g of sebacic acid, 250 g of UH-CARB90 (3 / 1) and 3.5 g of lithium hydroxide were added. Under the protection of nitrogen, the temperature is raised to effluent, the temperature of the distillation head is 90-103°C, and the temperature of the distillation head is raised to the highest reaction temperature of 230°C, the acid value of the resin is sampled and tested: 5.8mgKOH / g, when the cone-plate viscosity is 12.8P at 175°C, stop After reaction, the temperature was rapidly lowered to 90°C and the material was discharged to obtain the target water-resistant polyester resin. The alkyd feed ratio is 1.2:1.

[0023] The boiling-resistant polyest...

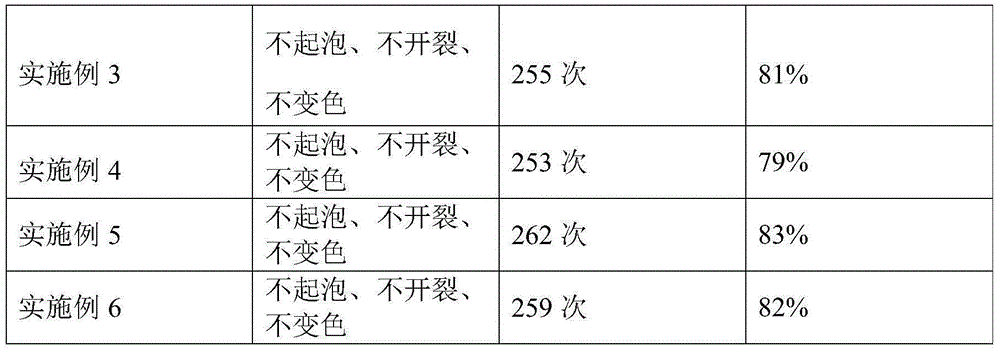

Embodiment 3

[0025] Add 215.9g of propylene glycol, 375.9g of neopentyl glycol and 412.8g of trimethylolethane into a reaction kettle with a stirrer and a temperature-rising reflux device, stir and feed nitrogen, and raise the temperature to 60-80°C until the material melts into liquid. Then 356.2 g of terephthalic acid, 564.4 g of isophthalic acid, 306.6 g of adipic acid, 256.3 g of UH-CARB90 (1 / 1) and 4 g of tetrabutyl titanate were added. Under the protection of nitrogen, the temperature is raised to effluent, the temperature of the distillation head is 90-103°C, and the temperature of the distillation head is raised to the highest reaction temperature of 225°C, and the acid value of the resin is sampled and tested: 3.5mgKOH / g, when the cone-plate viscosity is 10.5P at 175°C, stop After reaction, the temperature was rapidly lowered to 90°C and the material was discharged to obtain the target water-resistant polyester resin. The alkyd-acid feed ratio is 1.3:1.

[0026] The boiling-resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com