High-performance graphene/cellulose self-assembling composite hydrogel and aerogel and preparation method thereof

A composite hydrogel and cellulose technology, applied in the field of material science, can solve the problems of poor utilization of graphene and complex preparation process, etc., and achieve the effect of superior performance, simple preparation method, and superior material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 20 g of coniferous wood pulp, add 4000 ml of ultrapure water, soak overnight, and then decompose to obtain a cellulose dispersion with a concentration of 5 mg / ml.

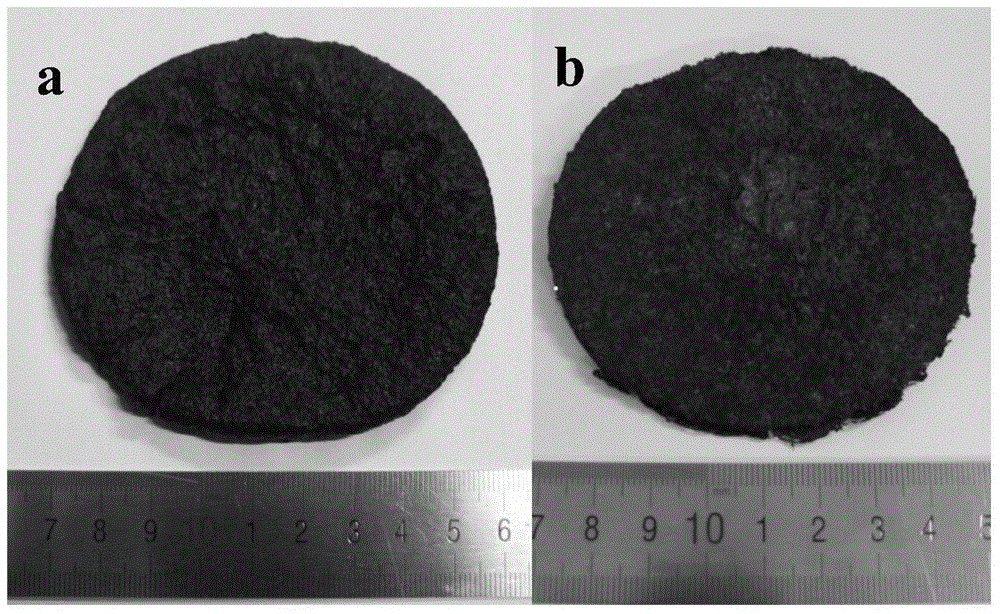

[0035] (2) The graphite oxide of 0.08g is added in the serum bottle that the cellulose dispersion in 8ml step (1) is housed, then add the water of 12ml, stir 15min, carry out ultrasonic dispersion with ultrasonic cleaner, its parameter condition is 100W ultrasound for one hour. Add 0.32g of vitamin C and react at 40°C for 10h. The cellulose fiber / graphene hydrogel is obtained, and then soaked in water for washing to obtain the final composite hydrogel, which is freeze-dried to composite aerogel.

Embodiment 2

[0037] (1) Take 20g of coniferous wood pulp, add 4000ml of ultra-pure water, soak overnight, and then decompose. A cellulose dispersion with a concentration of 5 mg / ml was obtained.

[0038] (2) The graphite oxide of 0.2g is added in the serum bottle that the cellulose dispersion in 80ml step (1) is housed, then adds the water of 20ml, stirs 15min, carries out ultrasonic dispersion with cell breaker, and its parameter condition is 600W ultrasonic crushing for 5min. Add 0.8g of vitamin C and react at 95°C for 10h. The cellulose fiber / graphene hydrogel is obtained, and then soaked in water for washing to obtain the final composite hydrogel, which is freeze-dried to composite aerogel.

Embodiment 3

[0040] (1) Take 10g of coniferous wood pulp, add 2000ml of ultrapure water, soak overnight, and then thaw out. A cellulose dispersion with a concentration of 5 mg / ml was obtained.

[0041] (2) Add 0.16g of graphite oxide to the beaker containing 32ml of the cellulose decomposing solution in step (1), then add 48ml of water, stir for 15min, and 100W ultrasonic for one hour. Add 0.8g of vitamin C and react at 95°C for 10h. The cellulose fiber / graphene hydrogel is obtained, and then soaked in water for washing to obtain the final composite hydrogel, which is freeze-dried to composite aerogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com