Interpenetrating polymer network modified pre-crosslinked profile control agent and preparation method thereof

An interpenetrating network and pre-crosslinking technology, applied in the field of interpenetrating network modified pre-crosslinking profile control agent and its preparation, can solve the problems of poor water retention performance, poor temperature resistance, low water absorption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

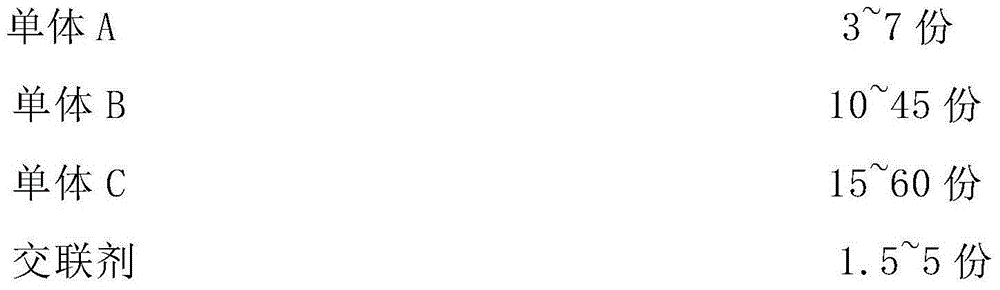

[0033] In this embodiment, an interpenetrating network modified pre-crosslinked profile control agent includes the following components, calculated in parts by mass:

[0034]

[0035] The monomer A is vulcanized polyvinyl alcohol, and the vulcanization process is to dissolve 7 g of polyvinyl alcohol in 100 ml of dimethyl sulfoxide solution, heat and stir in a water bath at 50 ° C, and then place it in an ice-water bath at 5 to 10 ° C. Add twice the volume of concentrated sulfuric acid for vulcanization, add the vulcanized polyvinyl alcohol to anhydrous acetone until white precipitates are precipitated, wash with anhydrous methanol, filter and dry.

[0036] The monomer B is acrylic acid.

[0037] The monomer C is gelatinized starch, and the gelatinization process is to stir and gelatinize in a constant temperature water bath at 80° C. for 30 minutes according to the mass ratio of deionized water:starch=9:1.

[0038] The crosslinking agent is N,N'-methylenebisacrylamide.

...

Embodiment 2

[0055] In this embodiment, an interpenetrating network modified pre-crosslinked profile control agent includes the following components, calculated in parts by mass:

[0056]

[0057] The monomer A is vulcanized polyvinyl alcohol, and the vulcanization process is to dissolve 7 g of polyvinyl alcohol in 100 ml of dimethyl sulfoxide solution, heat and stir in a water bath at 50 ° C, and then place it in an ice-water bath at 5 to 10 ° C. Add twice the volume of concentrated sulfuric acid for vulcanization, add the vulcanized polyvinyl alcohol to anhydrous acetone until white precipitates are precipitated, wash with anhydrous methanol, filter and dry.

[0058] The monomer B is acrylic acid.

[0059] The monomer C is gelatinized starch, and the gelatinization process is to stir and gelatinize in a constant temperature water bath at 80° C. for 30 minutes according to the mass ratio of deionized water:starch=9:1.

[0060] The crosslinking agent is N,N'-methylenebisacrylamide.

...

Embodiment 3

[0075] In this embodiment, an interpenetrating network modified pre-crosslinked profile control agent includes the following components, calculated in parts by mass:

[0076]

[0077] The monomer A is vulcanized polyvinyl alcohol, and the vulcanization process is to dissolve 7 g of polyvinyl alcohol in 100 ml of dimethyl sulfoxide solution, heat and stir in a water bath at 50 ° C, and then place it in an ice-water bath at 5 to 10 ° C. Add twice the volume of concentrated sulfuric acid for vulcanization, add the vulcanized polyvinyl alcohol to anhydrous acetone until white precipitates are precipitated, wash with anhydrous methanol, filter and dry.

[0078] The monomer B is acrylic acid.

[0079] The monomer C is gelatinized starch, and the gelatinization process is to stir and gelatinize in a constant temperature water bath at 80° C. for 30 minutes according to the mass ratio of deionized water:starch=9:1.

[0080] The crosslinking agent is N,N'-methylenebisacrylamide.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com