A kind of converter steelmaking method

A converter steelmaking and ton steel technology, applied in the direction of manufacturing converters, lime production, process efficiency improvement, etc., can solve the problems of high production cost of converter steelmaking, affecting the quality of molten steel, rising prices, etc., to improve the smelting process, Reduced erosion damage and reduced lime consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

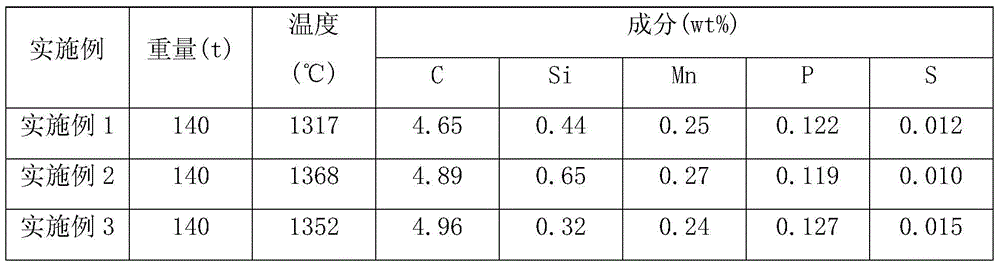

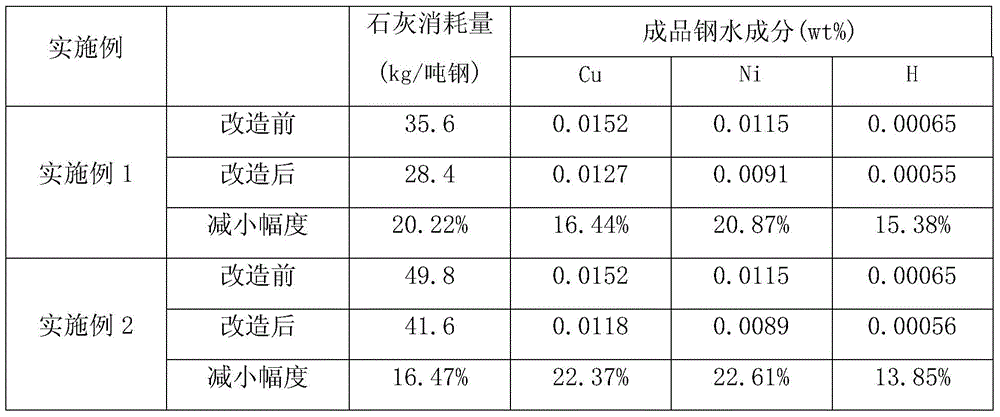

Embodiment 1

[0044] 1) First weigh iron oxide scale, dedusting ash and water of a certain quality, and control the dedusting ash to be the dust produced in the converter steelmaking process, including the following components in weight percentage: TFe: 50%, CaO: 8%, SiO 2 : 1%, MgO: 2%;

[0045] It is 3.5:5.5:1 to control the mass ratio of iron oxide scale, dedusting ash and water;

[0046] Then use a mixer to mix evenly, then feed the material to the brick press mold, and use a brick press to press and form the blank, then mix the blank, reducing agent and desulfurizing agent, put it into a refractory tank, and carry out reduction roasting treatment, select coke powder As a reducing agent, lime powder is selected as a desulfurizing agent, and the treatment temperature of the reduction roasting treatment is controlled to be 1150° C., and the treatment time is 18 hours to obtain reduced iron made from dedusting ash, which comprises the following components in weight percent: TFe:75 %, P: ...

Embodiment 2

[0052] 1) First weigh iron oxide scale, dedusting ash and water of a certain quality, and control the dedusting ash to be the dust produced in the converter steelmaking process, including the following components in weight percentage: TFe: 55%, CaO: 13%, SiO 2 : 1.1%, MgO: 3.5%;

[0053] Control the mass ratio of described iron oxide scale, dedusting ash and water to be 3:6:1;

[0054] Then use a mixer to mix evenly, then feed the material to the brick press mold, and use a brick press to press and form the blank, then mix the blank, reducing agent and desulfurizing agent, put it into a refractory tank, and carry out reduction roasting treatment, select coke powder As a reducing agent, lime powder is selected as a desulfurizing agent, and the treatment temperature of the reduction roasting treatment is controlled to be 1185° C., and the treatment time is 17 hours to obtain reduced iron made from dedusting ash. The reduced iron made from dedusting ash includes the following co...

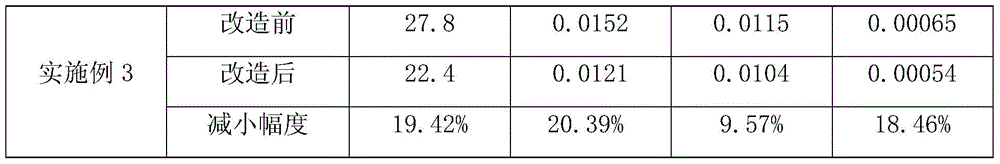

Embodiment 3

[0060] 1) First weigh iron oxide scale, dedusting ash and water of a certain quality, and control the dedusting ash to be the dust produced in the converter steelmaking process, including the following components in weight percentage: TFe: 60%, CaO: 18%, SiO 2 : 1.2%, MgO: 5%;

[0061] It is 2.5:6.5:1 to control the mass ratio of iron oxide scale, dedusting ash and water;

[0062] Then use a mixer to mix evenly, then feed the material to the brick press mold, and use a brick press to press and form the blank, then mix the blank, reducing agent and desulfurizing agent, put it into a refractory tank, and carry out reduction roasting treatment, select coke powder As a reducing agent, lime powder is selected as a desulfurizing agent, and the treatment temperature of the reduction roasting treatment is controlled to be 1220° C., and the treatment time is 16 hours to obtain reduced iron made from dedusting ash, which comprises the following components in weight percentage: TFe:80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com