Nitrogen-doped three-dimensional graphene loaded carbon coated copper substrate material and preparation method

A base material, graphene technology, applied in the direction of analysis of materials, material excitation analysis, material analysis by optical means, etc., to achieve the effect of easy operation, simple process, and convenient mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

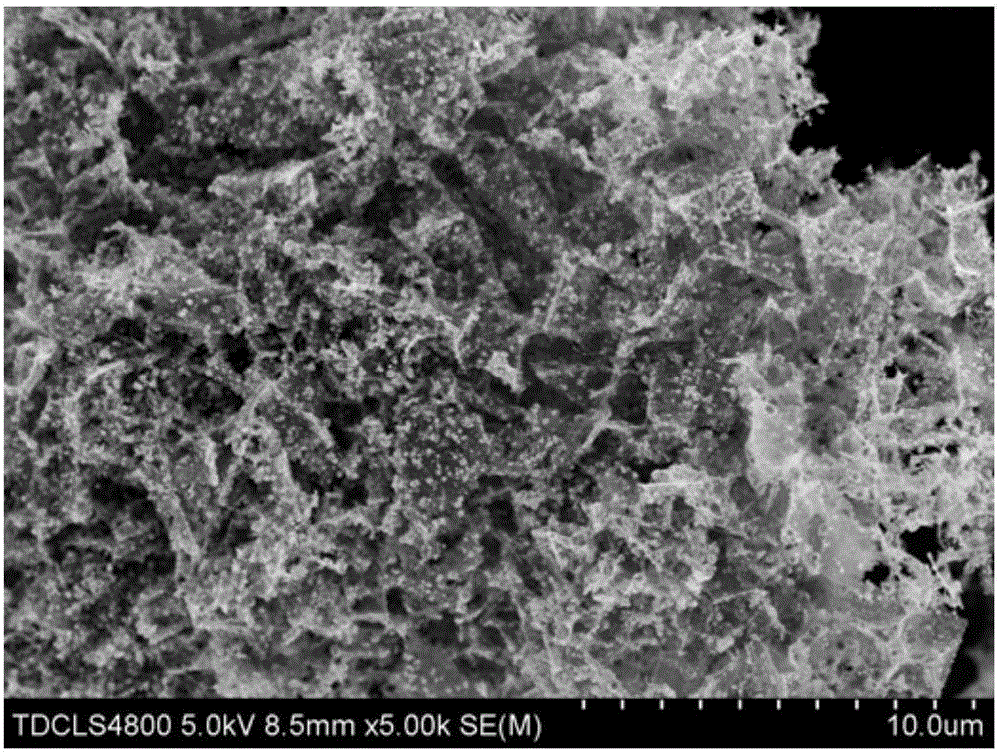

[0039] Mix 2.000g of powdered copper nitrate trihydrate as a copper source, 0.829g of carbon source glucose, and 32.300g of sodium chloride, dissolve in 107mL of deionized water, and stir evenly with a magnetic force; add drop by drop under stirring 9mL of 2mg / mL nitrogen source urea solution (so that the carbon-nitrogen atomic ratio is 98:2), the dropping speed is 1 drop / second, to obtain a uniform and transparent precursor solution; put the mixed solution in the refrigerator and freeze it at -20°C After 12 hours, a solid mixed sample was obtained, and then placed in a freeze dryer for 25 hours at a cold well temperature of -43°C for 25 hours, dehydrated to obtain a gel-like solid, ground and sieved to obtain a mixed powder precursor; 10 g of composite powder was placed in In the corundum ark, in a hydrogen atmosphere (gas flow rate of 100mL / min), the heating rate was 10°C / min to 750°C, kept for 2 hours, and then rapidly cooled (the average cooling rate was 100°C / min), and the...

Embodiment 2

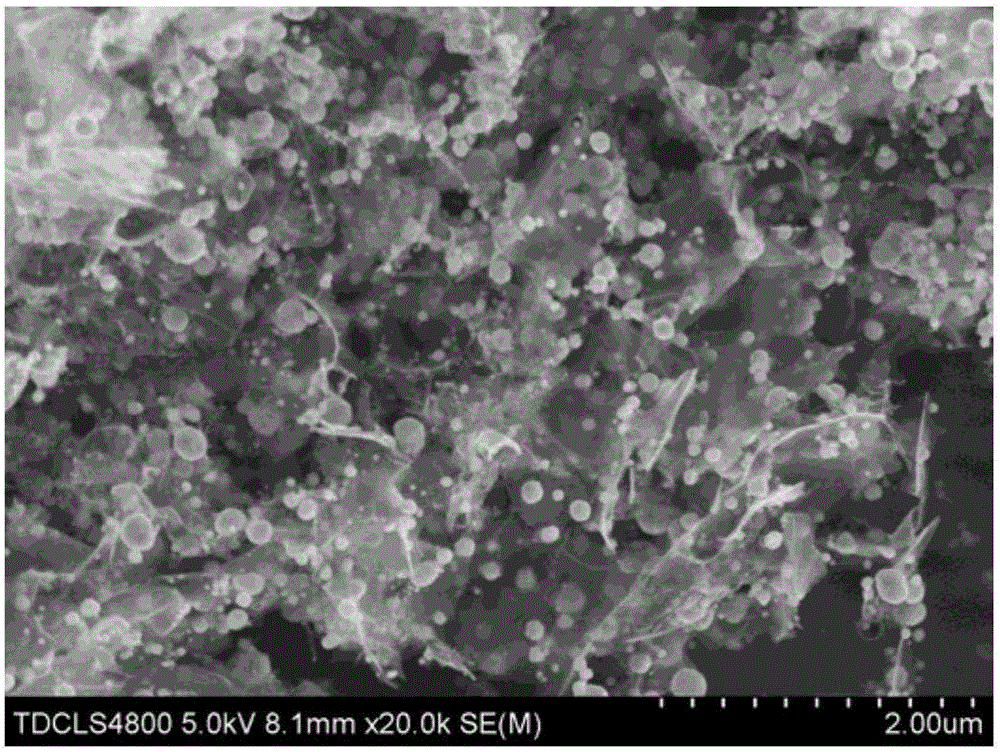

[0041] The process of preparing nitrogen-doped three-dimensional graphene-supported carbon-coated copper nanomaterials in this example is the same as that of Example 1, except that 9 mL of 2 mg / mL was added dropwise under stirring in Example 1. Change the nitrogen source urea solution to 22 mL of urea solution with a concentration of 2 mg / mL dropwise under stirring. Thus, a mixed precursor solution with an atomic ratio of carbon and nitrogen of 95:5 can be obtained. The nitrogen-doped three-dimensional graphene-supported carbon-coated copper nanomaterial powder material SEM photo 2 prepared by this example is shown in the figure.

Embodiment 3

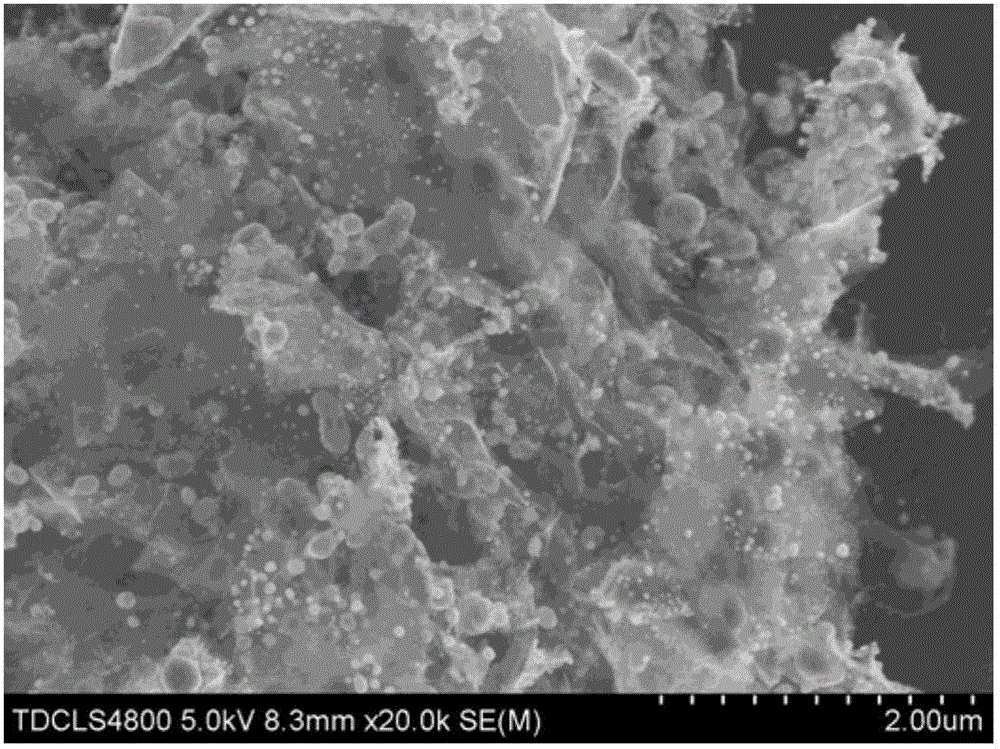

[0043] The process of preparing nitrogen-doped three-dimensional graphene-supported carbon-coated copper nanomaterials in this example is the same as that of Example 1, except that 9 mL of 2 mg / mL was added dropwise under stirring in Example 1. Change the nitrogen source urea solution to 44 mL of urea solution with a concentration of 2 mg / mL dropwise under stirring. Thus, a mixed precursor solution with an atomic ratio of carbon and nitrogen of 90:10 can be obtained. The SEM photos of the nitrogen-doped three-dimensional graphene-loaded carbon-coated copper nanomaterial powder material prepared by the present embodiment are as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com