In-situ preparation of NiCo2Sx and NiCo2O4 on conductive substrate and application of NiCo2Sx and NiCo2O4 in energy storage device

A conductive substrate, CO2 technology, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve the problems of activity reduction, deactivation, poisoning, etc., and achieve high methanol catalytic oxidation efficiency and high specific capacitance value, the effect of improving conductivity and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

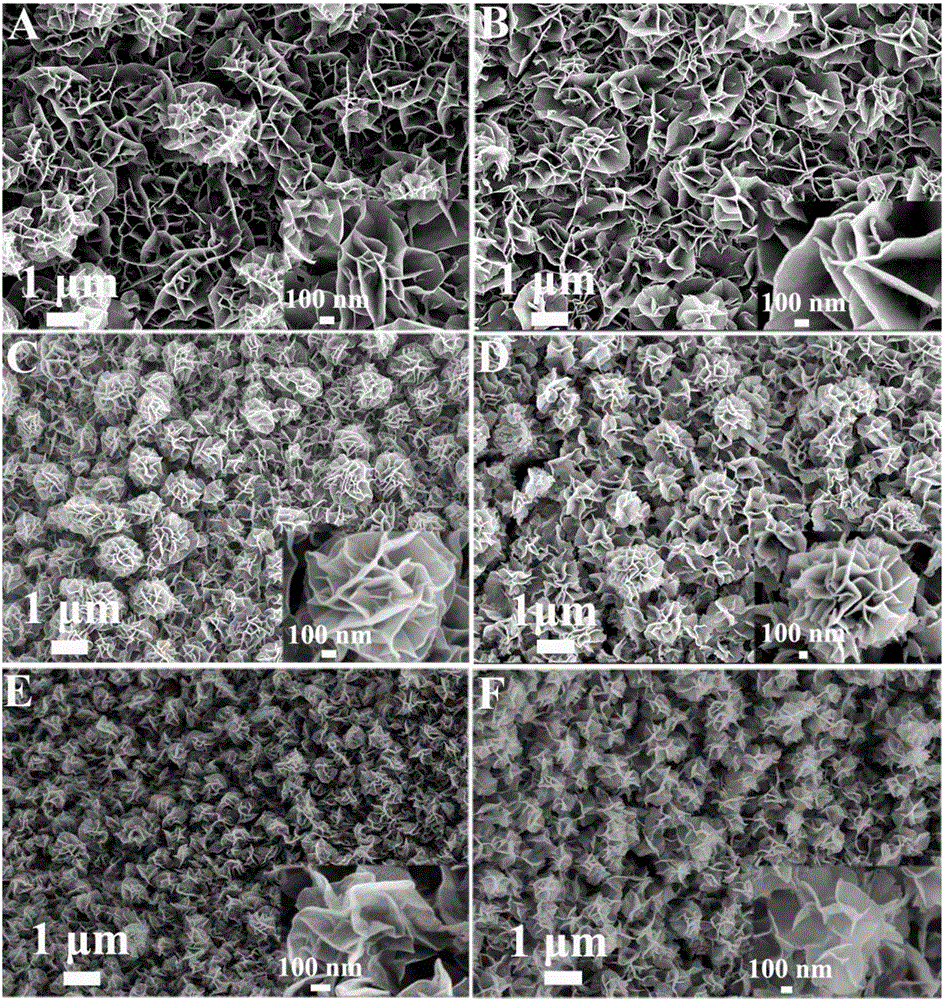

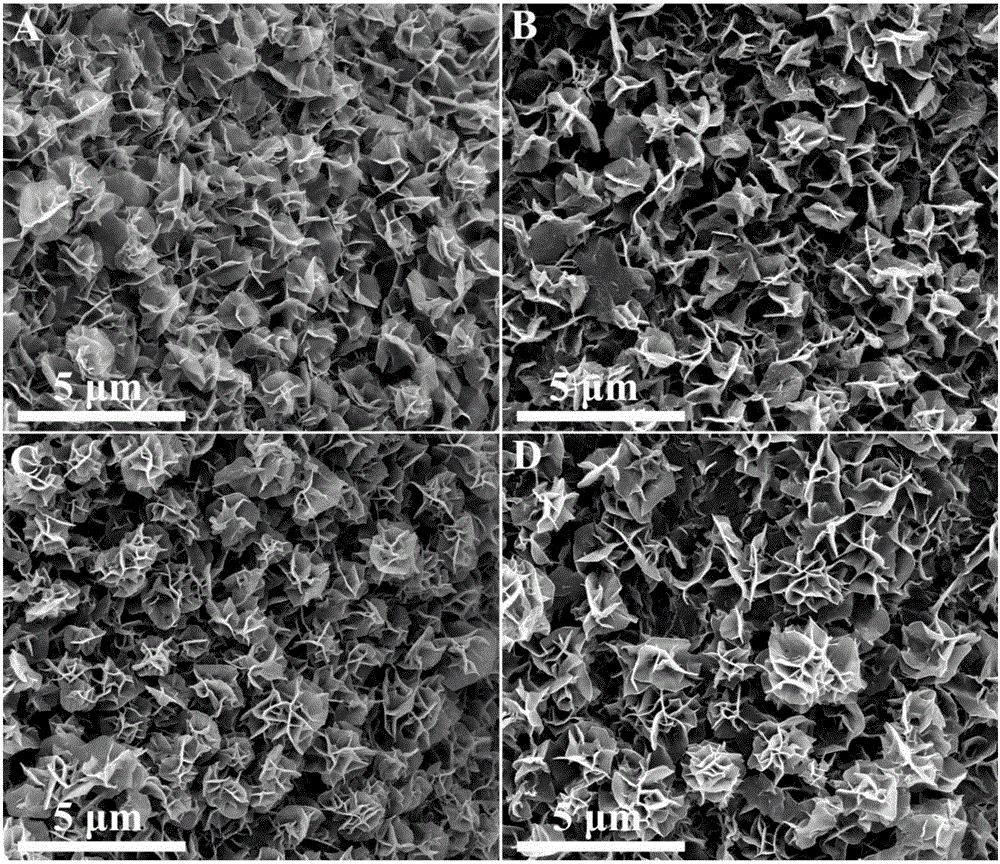

[0032] (1) configuration containing Ni 2+ and Co 2+ Aqueous solutions with a concentration of 5mmol / L and 10mmol / L were used as the electrolyte, the cleaned foamed nickel substrate was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the Pt electrode was used as the counter electrode. Deposit for 30 minutes, rinse with double distilled water and dry at 60°C to obtain Ni-CoLDHs / NF electrode;

[0033] (2) The Ni-CoLDHs / NF electrode obtained in (1) was calcined in a muffle furnace at 250°C for 3 hours to obtain NiCo that can be used in supercapacitors 2 o 4 / NF electrode;

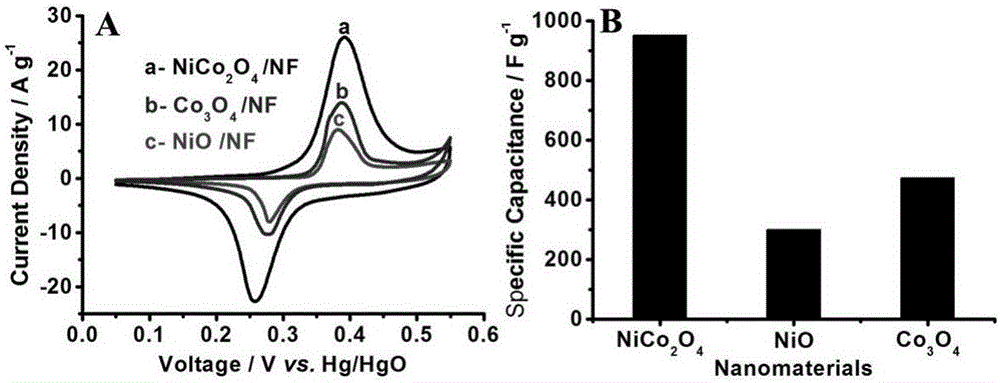

[0034] (3) NiCo in 6mol / L KOH electrolyte 2 o 4 / NF is the working electrode, Hg / HgO is the reference electrode, and graphite is the counter electrode. The capacitance performance test is carried out by cyclic voltammetry and constant current charge and discharge method. NiCo 2 o 4 / NF electrode showed better than NiO / NF and Co prepared by the same ...

Embodiment 2

[0036] (1) configuration containing Ni 2+ and Co 2+ Aqueous solutions with a concentration of 5mmol / L and 10mmol / L were used as the electrolyte, the cleaned foamed nickel substrate was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the Pt electrode was used as the counter electrode. Deposit for 30 minutes, rinse with double distilled water and dry at 60°C to obtain Ni-CoLDHs / NF electrode;

[0037] (2) Place the Ni-CoLDHs / NF electrode obtained in (1) in 0.1mol / L Na 2 React in S solution at room temperature (25°C) for 12 hours, rinse with double distilled water and dry at 60°C to obtain NiCo for supercapacitors. 2 S x / NF electrode;

[0038] (3) NiCo in 6mol / L KOH electrolyte 2 S x / NF is the working electrode, Hg / HgO is the reference electrode, and graphite is the counter electrode. The capacitance performance test is carried out by cyclic voltammetry and constant current charge and discharge method. NiCo 2 S x / N...

Embodiment 3

[0040] (1) configuration containing Ni 2+ and Co 2+ Aqueous solutions with a concentration of 10mmol / L and 20mmol / L were used as the electrolyte, a cleaned stainless steel mesh substrate was used as the working electrode, a saturated calomel electrode was used as the reference electrode, and a Pt electrode was used as the counter electrode. Deposit for 30 minutes, rinse with double distilled water and dry at 60°C to obtain Ni-CoLDHs / SS electrode;

[0041] (2) Place the Ni-CoLDHs / SS electrode obtained in (1) in 0.1mol / L Na 2 React in S solution at room temperature (25°C) for 12h, rinse with double distilled water and dry at 60°C to obtain NiCo for catalytic oxidation of methanol 2 S x / SS electrode;

[0042] (3) NiCo in 1mol / L KOH electrolyte 2 S x / SS is the working electrode, Hg / HgO is the reference electrode, and Pt is the counter electrode. Cyclic voltammetry and potentiostatic chronoamperometry are used to test the catalytic oxidation performance of methanol. NiCo 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com