Crystalline polyaryletherketone microsphere toughened polyaryletherketone material and preparation method thereof

A technology of polyaryletherketone and crystallinity, which is applied in the field of crystalline polyaryletherketone microsphere toughened polyaryletherketone materials and its preparation, can solve the problem of solvent resistance, cannot maintain crystallinity, and is not suitable for polyaryletherketone Ether ketone matrix and other problems, to achieve the effect of increasing interfacial force, excellent interfacial compatibility, and improving interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

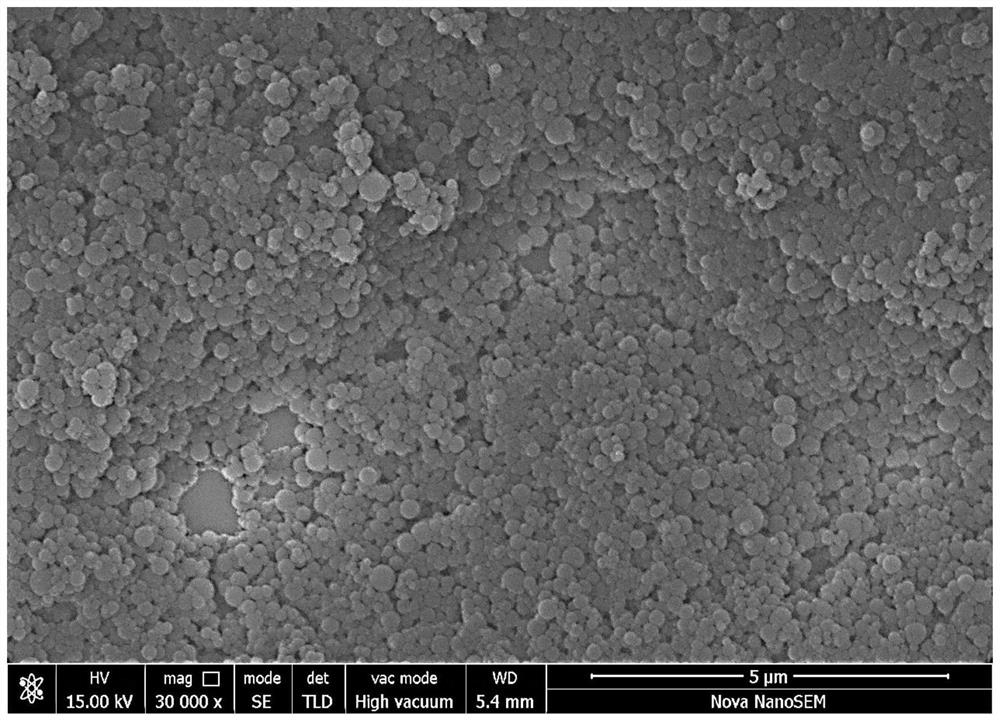

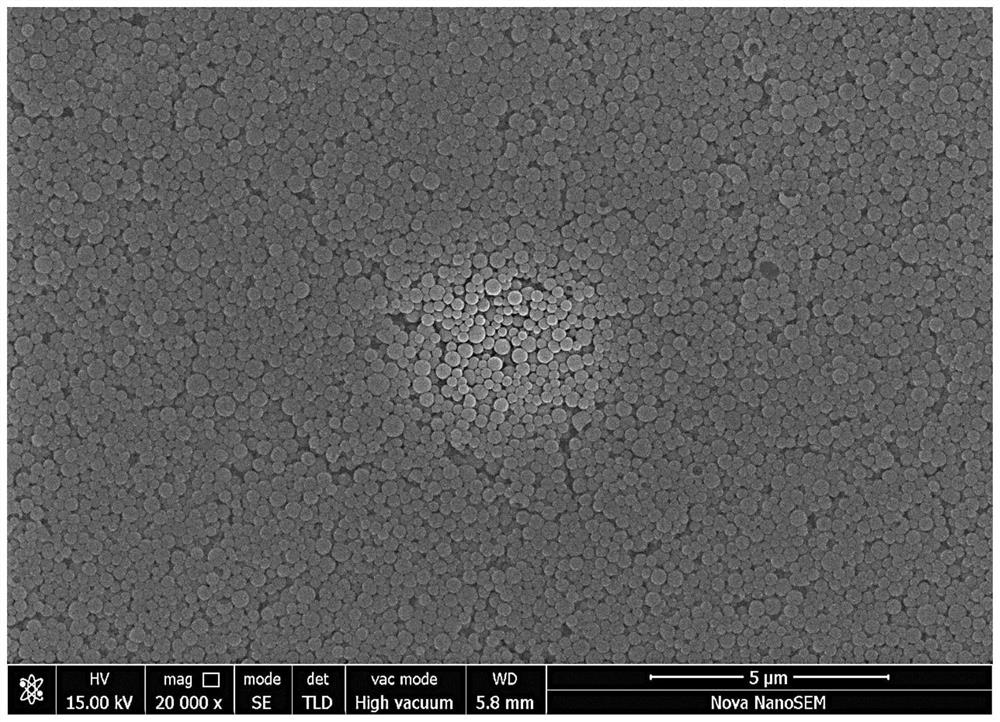

Image

Examples

Embodiment 1

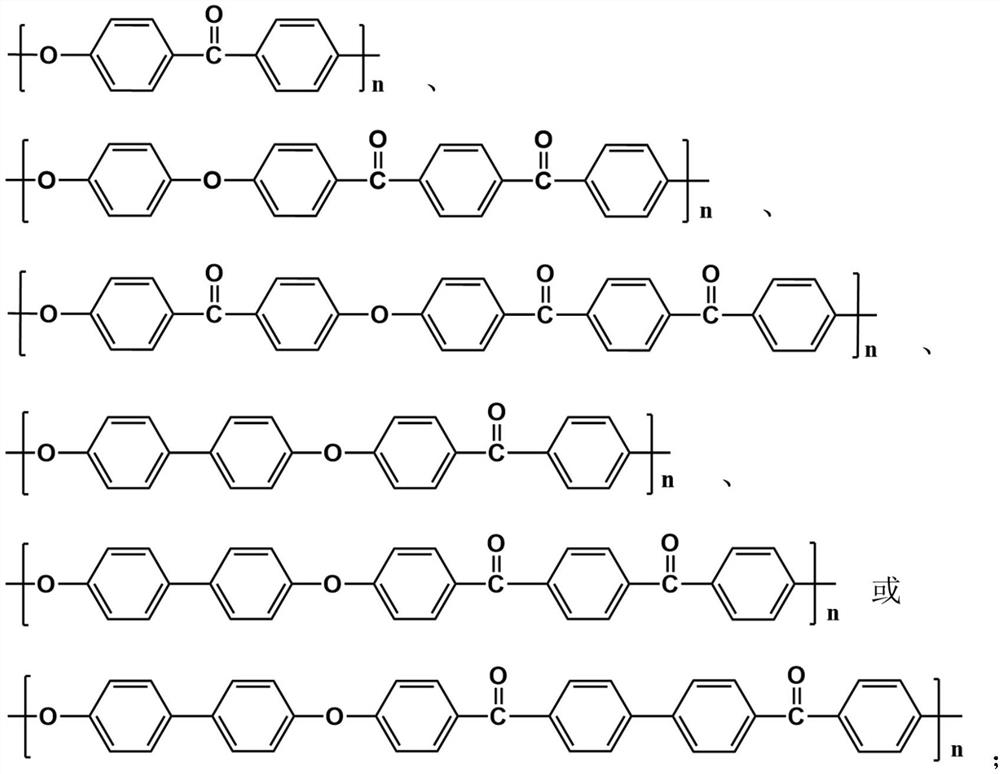

[0038] Pour PEKEKK (16.5g, n=60-70) into 500mL of dichloromethane under the condition of nitrogen protection and magnetic stirring, then add 80mL of trifluoroacetic acid, after PEKEKK is fully dissolved, add boron trifluoride ether to the solution in sequence (31.56mL, 0.25mol) and 1,2-ethanedithiol (10.96mL, 0.25mol), reacted at room temperature for 8 hours, and discharged in 3000mL of absolute ethanol. The white product was mechanically crushed and washed, and placed in a vacuum environment at 80°C Under drying for 8 hours to obtain a white solid product polyetheretherketone ether ketone-1,3-dithiolane;

[0039] N-bromosuccinimide (1.11g, 6.25mmol) and PEKEKK-1,3-dithiolane (4.53g, 6.25mmol) and ethylene glycol (0.35mL, 6.25mmol) were sequentially added to 400ml of dichloro In methane, react at room temperature under mechanical stirring for 5 minutes, discharge the product solution into 1000mL of anhydrous methanol, obtain a white powdery solid after filtration, wash the pro...

Embodiment 2

[0044] Pour PEK (19.6g, n=100-120) into 500mL of dichloromethane under the condition of nitrogen protection and magnetic stirring, then add 60mL of trifluoroacetic acid, after PEK is fully dissolved, add boron trifluoride ether into the solution in turn (31.56mL, 0.25mol) and 1,2-ethanedithiol (10.96mL, 0.25mol), after reacting at room temperature for 12h, the material was discharged in 3000mL of absolute ethanol, the white product was mechanically crushed and washed, and placed in a vacuum environment at 80°C Under drying for 8 hours to obtain a white solid product polyetherketone-1,3-dithiolane;

[0045] N-bromosuccinimide (2.22g, 12.5mmol) and PEK-1,3-dithiolane (1.79g, 6.25mmol) and ethylene glycol (0.35mL, 6.25mmol) were sequentially added to 400mL of dichloro In methane, react at room temperature under mechanical stirring for 10 minutes, discharge the product solution into 1000mL of anhydrous methanol, obtain a white powdery solid after filtration, wash the product and d...

Embodiment 3

[0049] Pour PEDEKK (21.8g, n=35-50) into 500mL of dichloromethane under the condition of nitrogen protection and magnetic stirring, then add 100mL of trifluoroacetic acid, after PEDEKK is fully dissolved, add boron trifluoride ether to the solution in sequence (31.56mL, 0.25mol) and 1,2-ethanedithiol (10.96mL, 0.25mol), after reacting at room temperature for 12h, the material was discharged in 3000mL of absolute ethanol, the white product was mechanically crushed and washed, and placed in a vacuum environment at 80°C Drying at lower temperature for 8 hours to obtain a white solid product biphenyl type PEEK-1,3-dithiolane;

[0050] N-bromosuccinimide (2.22g, 12.5mmol) and PEDEKK-1,3-dithiolane (3.88g, 6.25mmol) and ethylene glycol (0.35mL, 6.25mmol) were added to 500mL dichloro In methane, react at room temperature under mechanical stirring for 15min, discharge the product solution into 1000mL of anhydrous methanol, obtain a white powdery solid after filtration, wash the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com