Crystalline silicon solar cell and diffusion method therefor

A technology of solar cells and diffusion methods, applied in the field of crystalline silicon solar cells and their diffusion, can solve the problems of high doping concentration, low short-circuit current, and reduced minority carrier lifetime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

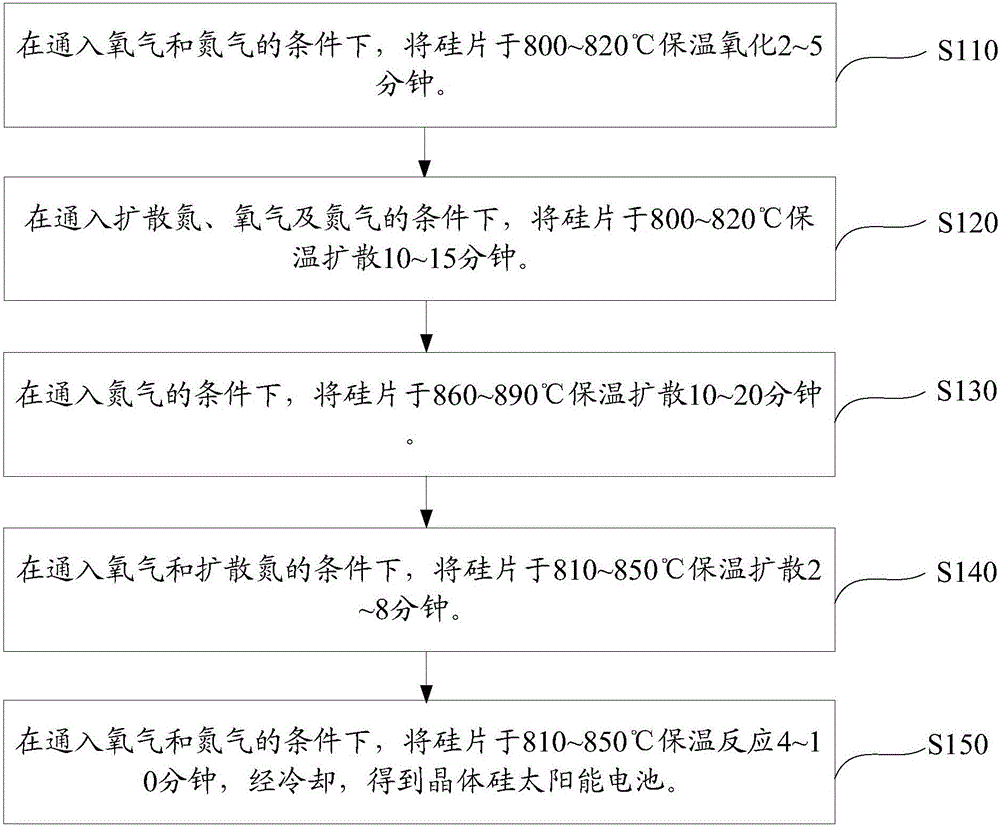

[0055] The diffusion steps of the crystalline silicon solar cell of the present embodiment are as follows:

[0056] (1) Insert the silicon chip after the texturing in the groove of the quartz boat, and place a piece of silicon chip in each groove, the thickness of the silicon chip is 170 microns, the quartz boat with the silicon chip will be inserted in the drive of the guide rail down into the diffusion furnace.

[0057] (2) Heat up the diffusion furnace to 800° C., feed oxygen and nitrogen into the diffusion furnace, keep warm and diffuse for 2 minutes, wherein the flow rate of oxygen is 1000 sccm, and the flow rate of nitrogen gas is 30 slm.

[0058] (3) Feed the first diffusion nitrogen, oxygen and nitrogen into the diffusion furnace, and insulate and diffuse at 800°C for 15 minutes, wherein the flow of the first diffusion nitrogen is 2000sccm, the flow of oxygen is 1000sccm, and the flow of nitrogen is 30slm.

[0059] (4) The temperature of the diffusion furnace was rais...

Embodiment 2

[0065] The diffusion steps of the crystalline silicon solar cell of the present embodiment are as follows:

[0066] (1) Insert the silicon chip after texturing in the groove of the quartz boat, and place a piece of silicon chip in each groove. The thickness of the silicon chip is 200 microns, and the quartz boat inserted with the silicon chip is driven by the rail down into the diffusion furnace.

[0067] (2) Heat up the diffusion furnace to 820° C., feed oxygen and nitrogen into the diffusion furnace, keep warm and diffuse for 5 minutes, wherein the flow rate of oxygen is 2000 sccm, and the flow rate of nitrogen is 18 slm.

[0068] (3) Feed the first diffusion nitrogen, oxygen and nitrogen into the diffusion furnace, and insulate and diffuse at 820° C. for 10 minutes, wherein the flow of the first diffusion nitrogen is 3500 sccm, the flow of oxygen is 2000 sccm, and the flow of nitrogen is 18 slm.

[0069] (4) The temperature of the diffusion furnace was raised to 890° C., a...

Embodiment 3

[0075] The diffusion steps of the crystalline silicon solar cell of the present embodiment are as follows:

[0076] (1) Insert the silicon chip after texturing in the groove of the quartz boat, and place a piece of silicon chip in each groove. The thickness of the silicon chip is 200 microns, and the quartz boat inserted with the silicon chip is driven by the rail down into the diffusion furnace.

[0077] (2) Heat up the diffusion furnace to 810° C., feed oxygen and nitrogen into the diffusion furnace, keep warm and diffuse for 3 minutes, wherein the flow rate of oxygen is 1500 sccm, and the flow rate of nitrogen gas is 24 slm.

[0078] (3) Feed the first diffusion nitrogen, oxygen and nitrogen into the diffusion furnace, and insulate and diffuse at 810° C. for 12 minutes, wherein the flow of the first diffusion nitrogen is 3000 sccm, the flow of oxygen is 1500 sccm, and the flow of nitrogen is 24 slm.

[0079] (4) The temperature of the diffusion furnace was raised to 870° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com