Back contact type solar cell based on P-type silicon substrate and manufacturing method thereof

A solar cell and back-contact technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor surface coverage uniformity of silicon wafers, complex battery process control, and greater influence of P-type silicon wafers. Treatment, reduced surface recombination, easy to pinpoint the effect of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

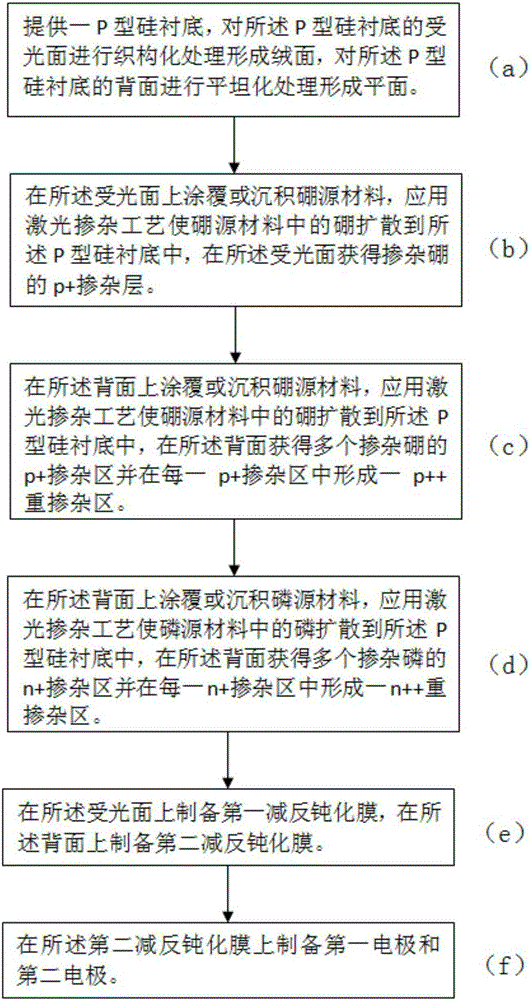

[0033] Introduce the preparation method of above-mentioned solar cell below, as image 3 As shown, the method includes the steps of:

[0034] (a) A P-type silicon substrate is provided, the light-receiving surface of the P-type silicon substrate is textured to form a textured surface, and the back surface of the P-type silicon substrate is planarized to form a plane.

[0035] (b) Coating or depositing a boron source material on the light-receiving surface, applying a laser doping process to diffuse boron in the boron source material into the P-type silicon substrate, and obtaining a boron-doped silicon substrate on the light-receiving surface p+ doped layer. Wherein, the boron source material is selected from boric acid solution, borosilicate glass, boron-containing silicon nitride, boron-containing silicon oxide or boron-containing amorphous silicon.

[0036] (c) Coating or depositing a boron source material on the back surface, applying a laser doping process to diffuse bo...

Embodiment 1

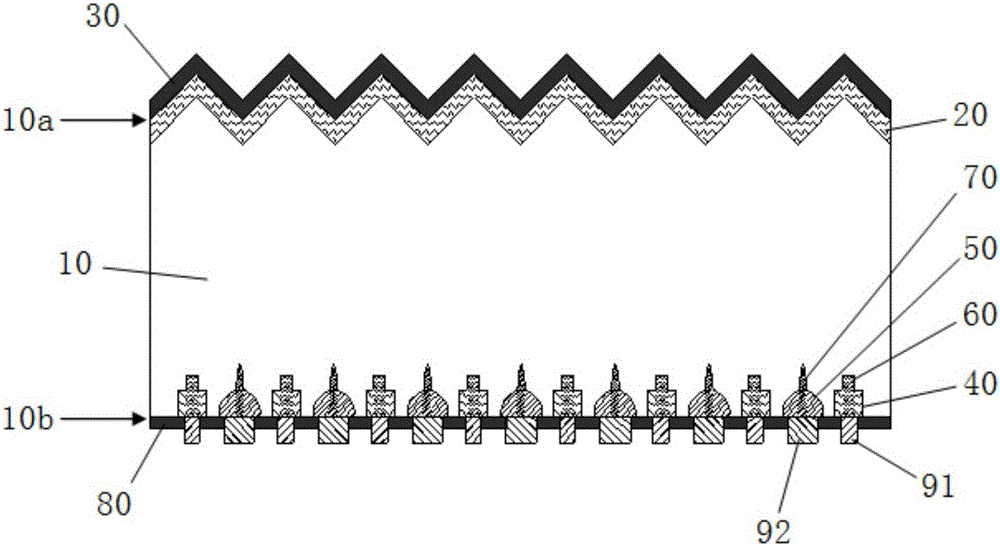

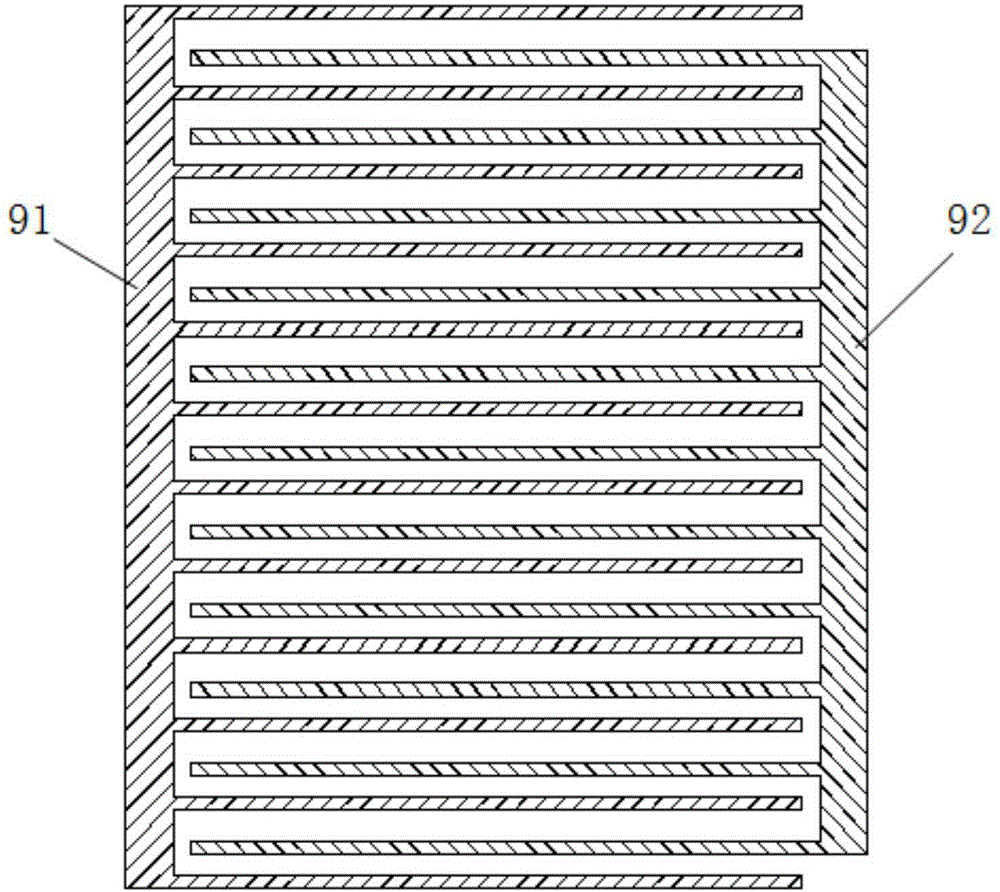

[0046] 1. If Figure 4a As shown, firstly, a P-type silicon substrate 10 is provided, which includes a light-receiving surface 10a and a back surface 10b opposite to each other. Surface texturing treatment is carried out on the light-receiving surface 10a of the P-type silicon substrate 10: specifically, a mixed solution of potassium hydroxide or sodium hydroxide, IPA and texturing additives can be used for surface treatment, and the surface is pyramid-shaped. surface structure; after the texturing treatment, the silicon substrate 10 is chemically cleaned. Perform planarization treatment on the back surface 10b of the P-type silicon substrate 10: specifically, first use SiO on the light-receiving surface 10a 2 、SiN x etc. to protect the dielectric film, and then directly etch the backside in potassium hydroxide or sodium hydroxide alkali solution (10% mass fraction), or use HF / HNO 3 The mixed acid solution is used for back etching, and after the etching is completed, the si...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, the order of Step 2 and Step 3 in Embodiment 1 is reversed, that is, after the P-type silicon substrate 10 is processed, an n+ doped substrate is first prepared on the back surface 10b. For the impurity region 50 and the n++ heavily doped region 70, refer to step 3 in Embodiment 1; Step 2 in Example 1. The rest of the steps are the same as those in Embodiment 1 and will not be repeated here.

[0054] Compared with the prior art, the present invention uses a P-type silicon chip as the substrate material, which is low in cost and widely used. Back planarization treatment, that is, back polishing, is conducive to the formation of uniform PN junctions and PP+ high-low junctions on the back, while reducing the specific surface area of the back and reducing surface recombination. The doping source adopts liquid or solid state, which is safe and reliable, and is also conducive to laser trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com