Silicon nanowire radial heterojunction solar battery manufacture method

A technology of solar cells and silicon nanowires, applied in nanotechnology, circuits, photovoltaic power generation, etc., can solve problems such as unsatisfactory passivation effect, unstable plasma, difficult conformal deposition of amorphous silicon thin films, etc., and achieve a good interface Passivation effect, efficiency improvement, effect of reducing sample surface recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

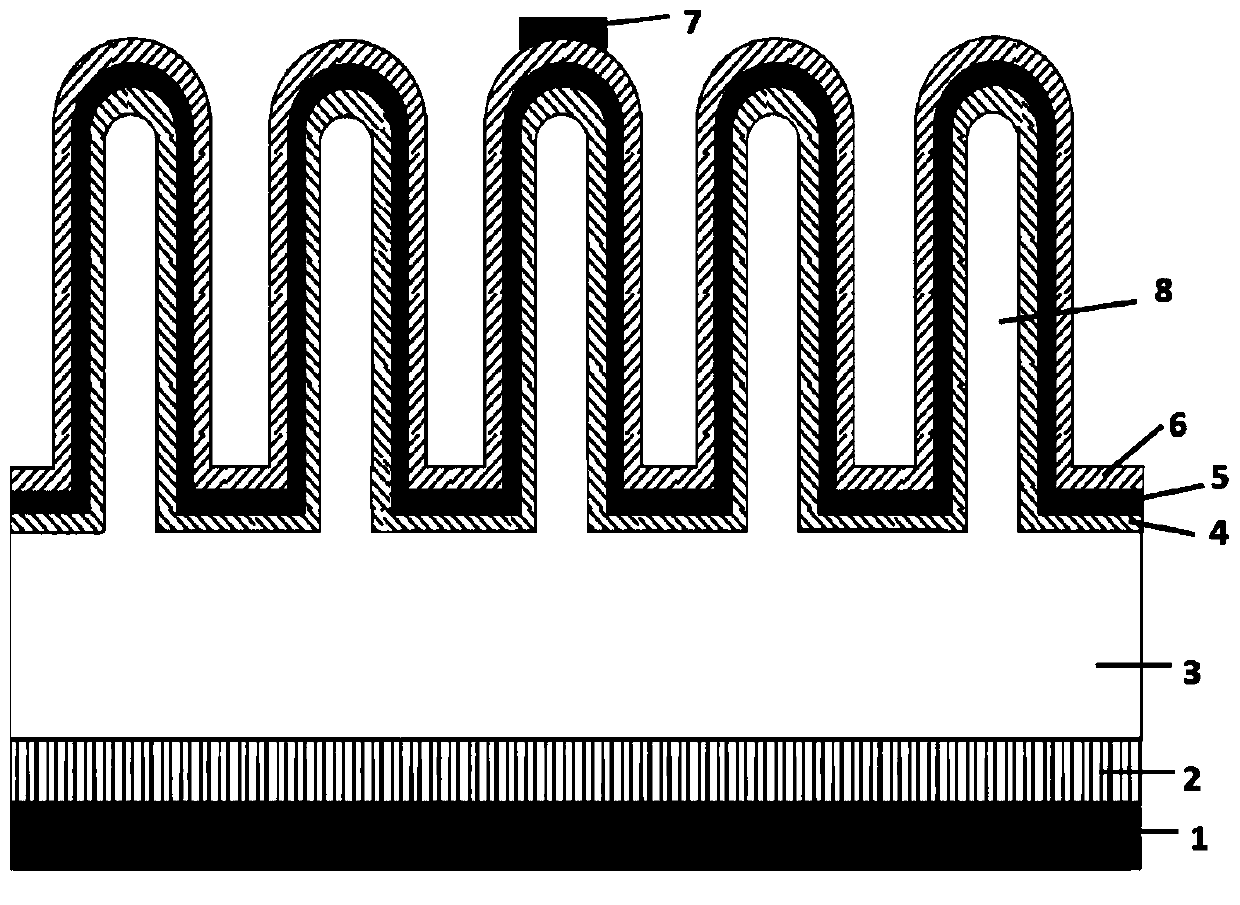

[0024] The preparation method of the silicon nanowire radial heterojunction solar cell proposed by the present invention, the structure of the solar cell is as follows figure 1 shown, including the following steps:

[0025] (1) Forming vertical nanowires 8 with a diameter of 20 to 2000 nanometers and a height of 100 to 10000 nanometers on the upper surface of the p-type single crystal silicon wafer 3 by wet etching, and placing the nanowires 8 on the upper surface Silicon wafers are cleaned;

[0026] (2) Put the sample obtained in step (1) into the cavity of the thermal evaporation equipment, and the vacuum in the cavity reaches 3×10 -4 After Pa, high-purity aluminum is evaporated, and a metal aluminum film with a thickness of 1-2 microns is deposited on the lower surface of the sample;

[0027] (3) Put the sample obtained in step (2) into a quartz furnace, pass a mixed gas of nitrogen and oxygen, wherein the volume ratio of nitrogen and oxygen is 95:5, and keep it at 930°C ...

Embodiment 1

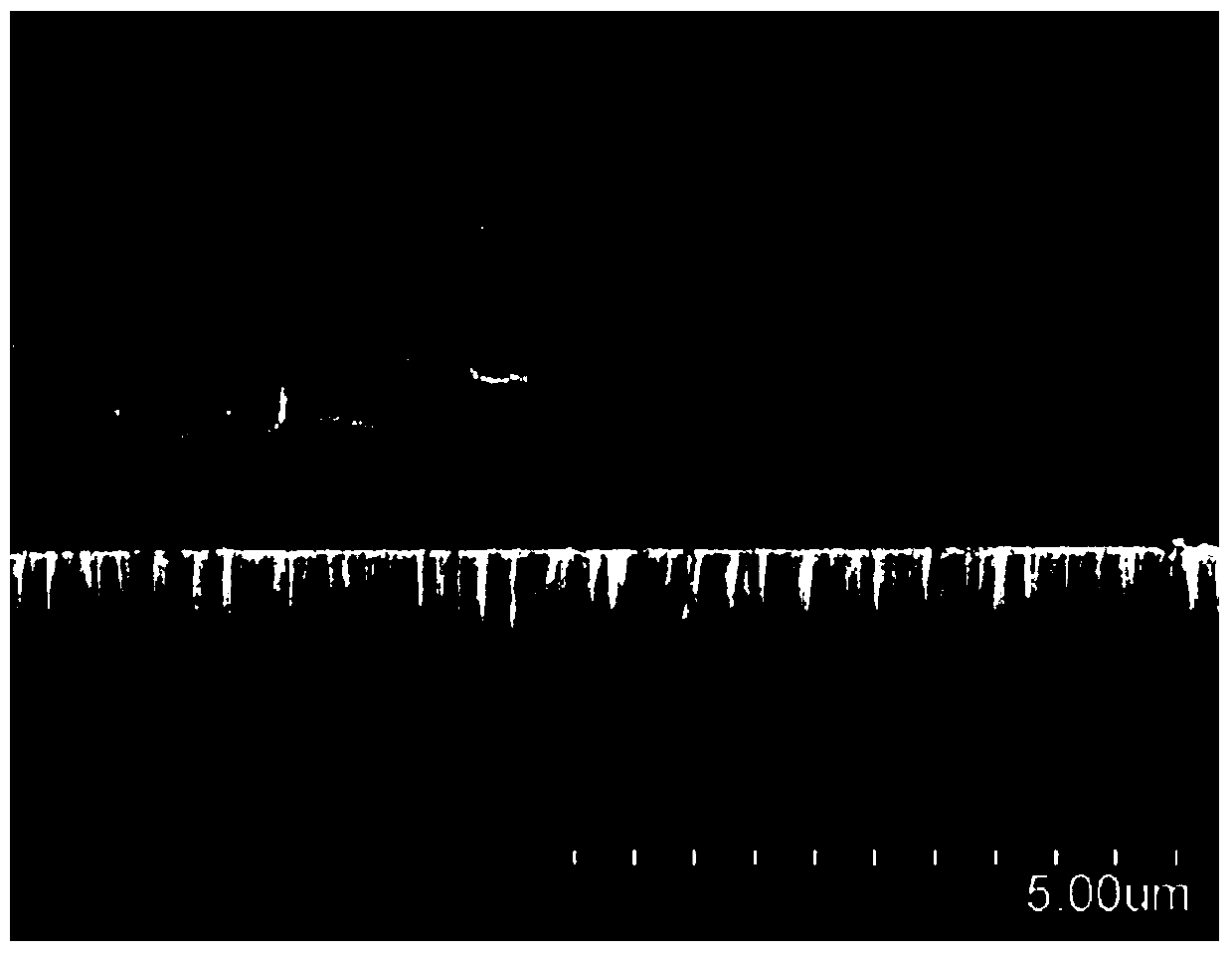

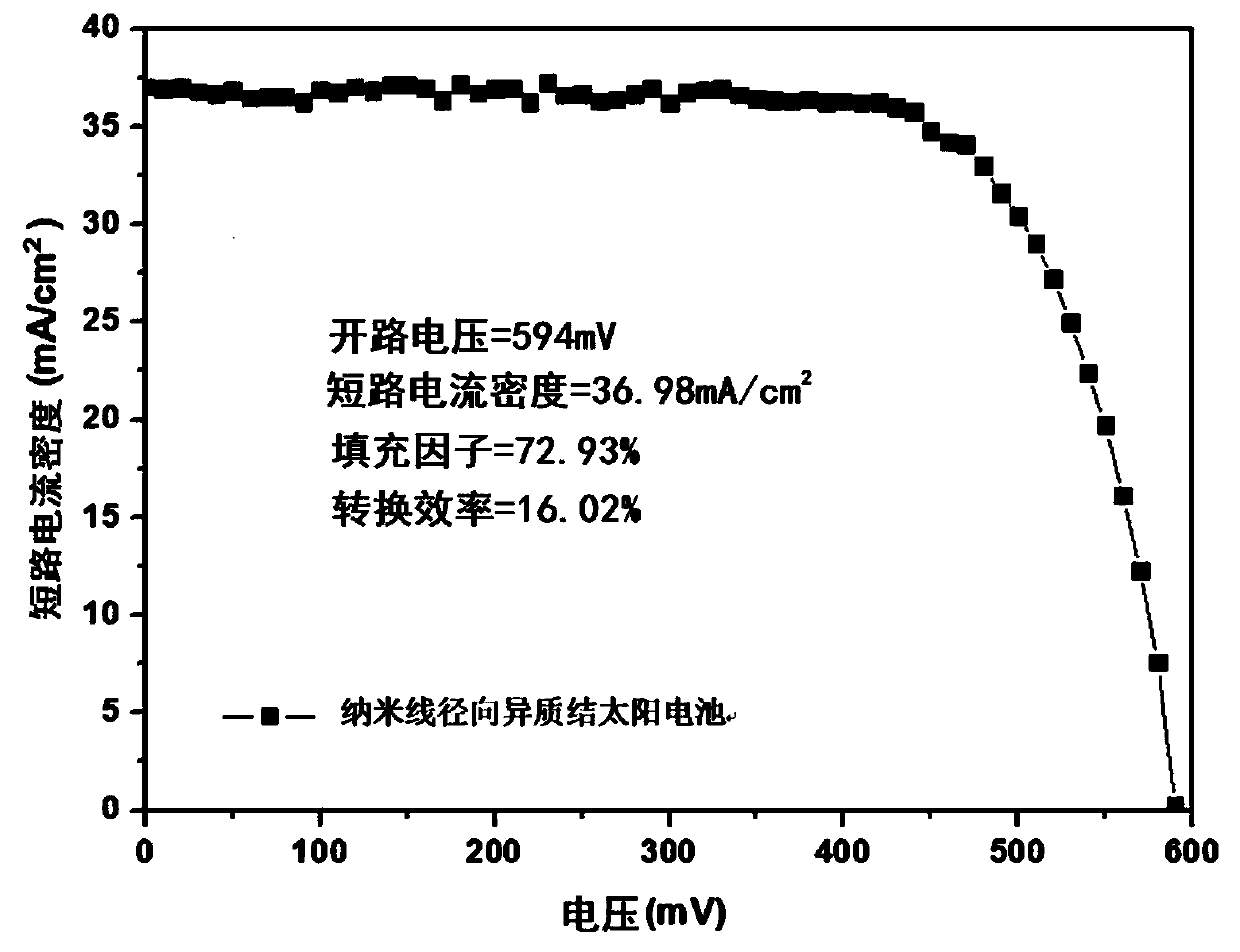

[0039] (1) Use wet etching to etch the upper surface of p-type single crystal silicon wafer (zone melting single crystal, crystal orientation, resistivity 1~3Ω·cm) to form nanowires with a height of 6000 nanometers , put the sample in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, wash it at 120°C for 30 minutes, wherein the volume fraction ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3, and then clean it with deionized water; then, put the sample in ammonia water , hydrogen peroxide and isopropanol in a mixed aqueous solution, washed at 80 ° C for 10 minutes, and then cleaned with deionized water, wherein the volume fraction ratio of ammonia, hydrogen peroxide, isopropanol and water is 1:2:0.5:5, Finally, the sample was placed in an aqueous solution of hydrochloric acid and hydrogen peroxide, washed at 80°C for 7 minutes, and then thoroughly cleaned with deionized water for later use. The volume fraction ratio of hydrochloric acid, hyd...

Embodiment 2

[0049] (1) Use wet etching to etch nanowires on the surface of p-type single crystal silicon wafers (zone melting single crystal, crystal orientation, resistivity 1-3Ω·cm), the height of the nanowires is 1000 nm, and the sample Put it into a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and wash it at 120°C for 30 minutes, wherein the volume fraction ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3, and then clean it with deionized water; then, put the sample into ammonia water, hydrogen peroxide and In a mixed aqueous solution of isopropanol, wash at 80°C for 10 minutes, and then clean it with deionized water. The volume fraction ratio of ammonia water, hydrogen peroxide, isopropanol and water is 1:2:0.5:5, and finally put the sample Put it into an aqueous solution of hydrochloric acid and hydrogen peroxide, wash it at 80°C for 7 minutes, and then wash it thoroughly with deionized water for later use. The volume fraction ratio of hydrochl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com