Molybdenum sulfide functional carbon nano tube Pt-carried catalyst for direct methanol fuel cell and preparation method of catalyst

A methanol fuel cell, carbon nanotube technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as small specific surface area, application limitations, and the influence of catalyst electro-oxidation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

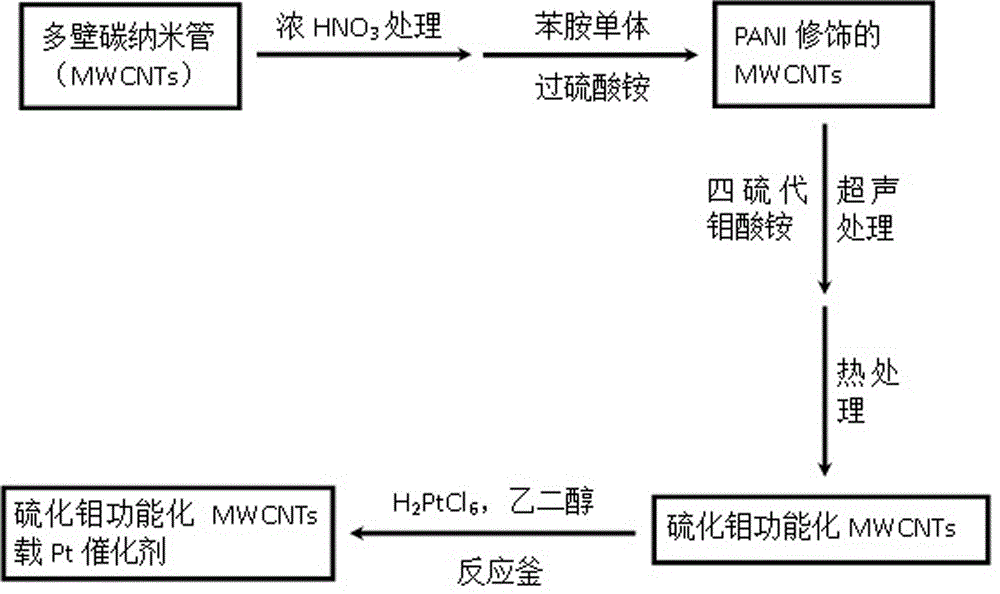

[0023] Such as figure 1 As shown, a method for preparing a molybdenum sulfide functionalized carbon nanotube-supported Pt catalyst for a direct methanol fuel cell includes the following steps:

[0024] 1) Add 20mg of acidified MWCNTs, 400μL of concentrated hydrochloric acid and 20~300μL of aniline monomer to a container filled with three times distilled water, 100μL in this example, magnetic stirring at room temperature for 12 hours, then add 0.4g (NH 4 ) 2 S 2 O 8 Solid, continue to stir for 12 hours, the resulting product is centrifuged, washed and vacuum dried to obtain PANI modified MWCNTs composite material PANI-MWCNTs;

[0025] 2) Weigh 10 mg of PANI-MWCNTs sample and disperse in 5 mL 0.16 mg mL ultrasonically -1 In the ethanol solution of ammonium tetrathiomolybdate, ultrasonic treatment until the solvent is completely volatilized, the solid obtained is placed in a quartz tube furnace under the protection of nitrogen at 300-1000°C for 3 hours. The heat treatment temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com