Instant original taste pachyrhizus erosus crisp chip processing method

A processing method and technology of jicama, which is applied in the processing field of instant raw jicama chips, can solve problems such as difficult storage and transportation, economical income does not necessarily increase, and no process reports have been seen, so as to achieve easy chewing and digestion, and improve market competition The effect of low power and drying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Choose the ripe jicama with no pests and diseases, no damage, as the raw material, wash with tap water to remove the soil and impurities on the surface of the jicama, remove the skin and roots, and then use a slicer to cut into disc-shaped jicama chips with a thickness of 2mm. Immediately immerse in clean water, and freeze in a -40°C freezer for 1 hour. Place the frozen jicama chips on a microwave tray, and quickly ripen them with a power of 800W for 4 minutes, spread them in a single layer on the separator, place them in a blast drying oven at 65°C, and dry them until the moisture content on a wet basis is 5%. ~12%, after the product cools down, it is immediately packaged in a high-barrier food-grade aluminum foil composite bag to ensure the crispness of the product.

Embodiment 2

[0021] Select the ripe jicama with no pests, no damage, as the raw material, wash with tap water to remove the soil and impurities on the surface of the jicama, remove the skin and roots, and then use a slicer to cut into disc-shaped jicama chips with a thickness of 4mm. Immediately immerse in clean water, and then freeze in a -60°C freezer for 2 hours. Put the frozen jicama chips on a microwave plate, and quickly ripen them with 1000W power for 3 minutes, spread them on the separator in a single layer, put them in a blast drying oven at 75°C, and dry them until the moisture content on a wet basis is 5%~ 12%, after the product is cooled, it is immediately packaged in a high-barrier food-grade aluminum foil composite bag to ensure the crispness of the product.

Embodiment 3

[0023] Select the ripe jicama with no pests, no damage, as the raw material, wash with tap water to remove the soil and impurities on the surface of the jicama, remove the skin and roots, and then use a slicer to cut into disc-shaped jicama chips with a thickness of 6 mm. Immediately immerse in clean water, and then freeze in a -80°C freezer for 3 hours. Put the frozen jicama chips on a microwave plate, and quickly ripen them with 1000W power for 4 minutes, spread them on the separator in a single layer, put them in a blast drying oven at 90°C, and dry them until the moisture content on a wet basis is 5%~ 12%, after the product is cooled, it is immediately packaged in a high-barrier food-grade aluminum foil composite bag to ensure the crispness of the product.

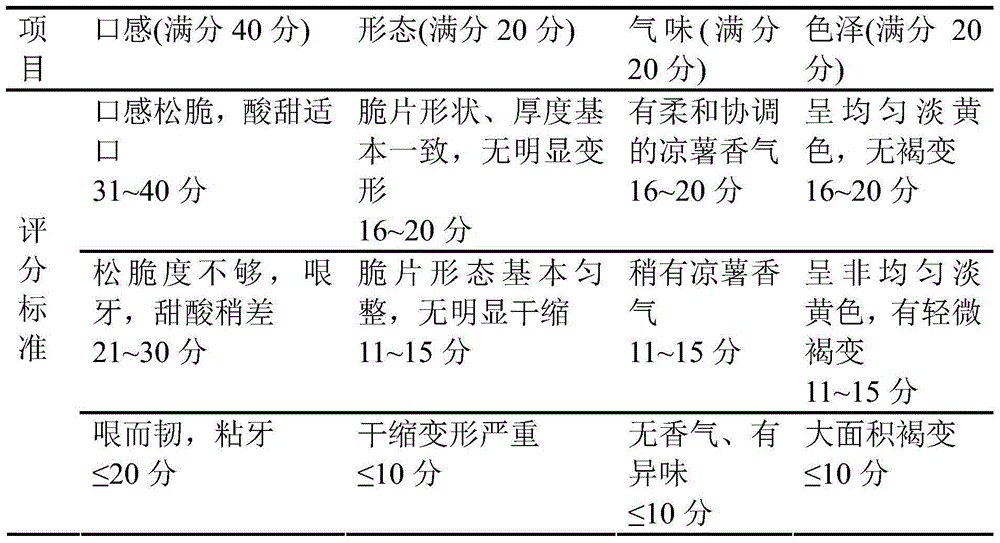

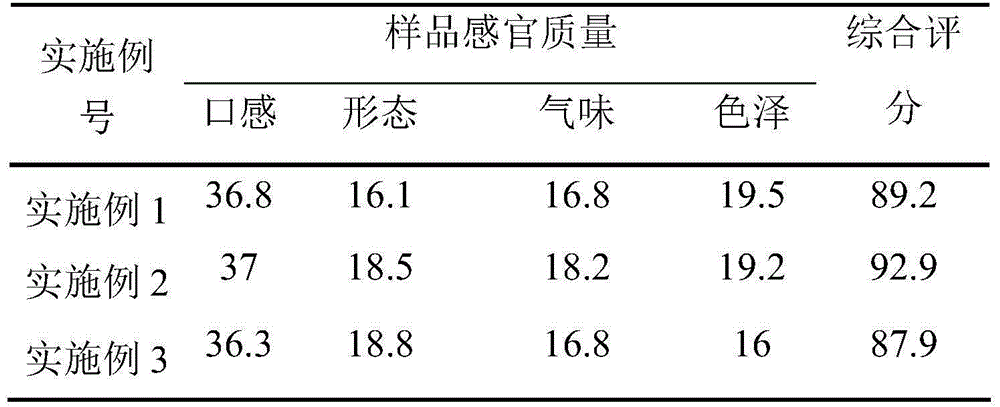

[0024] Adopt sensory evaluation method to the original taste cold potato chips that embodiment 1-3 makes, from mouthfeel, form, smell, color and luster four aspects, and according to smell mouthfeel (40%), form (20%), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com