A sludge microwave infrared coupling low temperature drying equipment

A microwave infrared and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Wear and tear and other problems, to reduce the risk of high-voltage electric injury, avoid burns, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

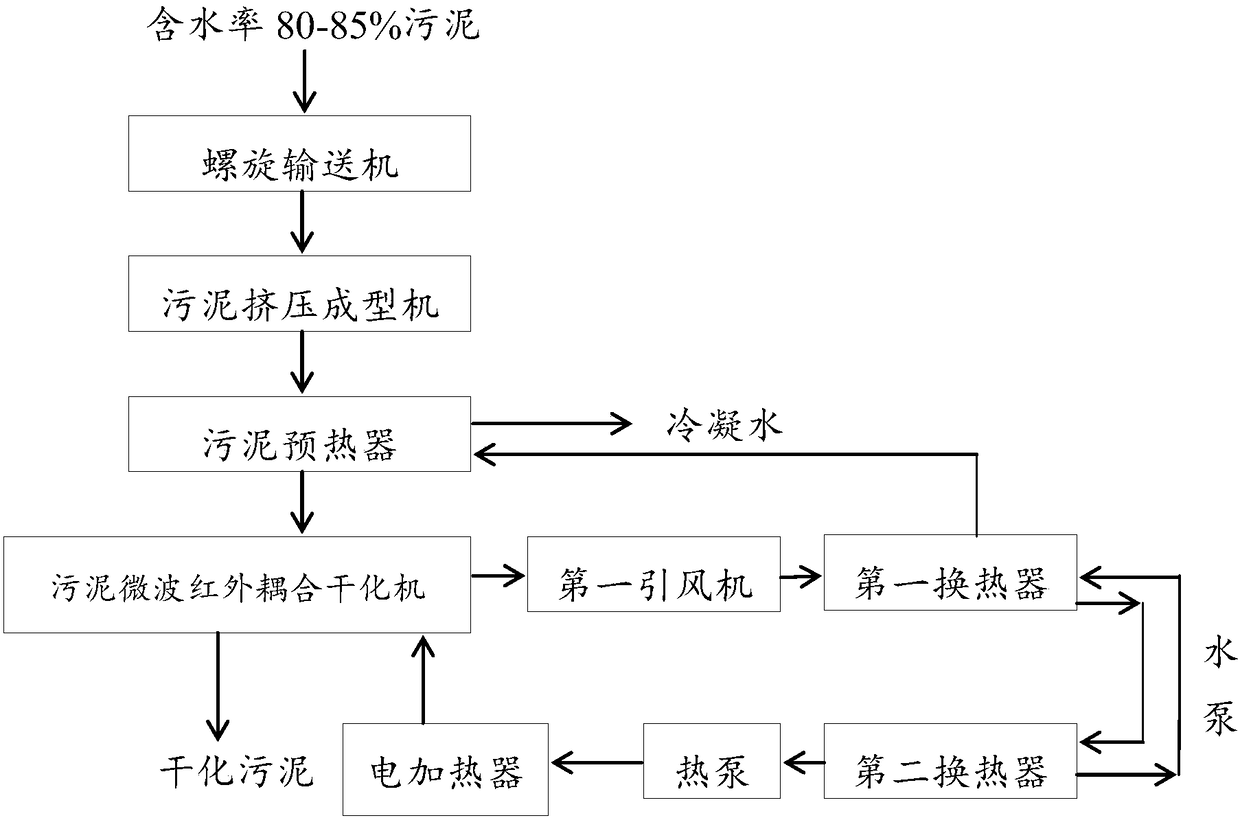

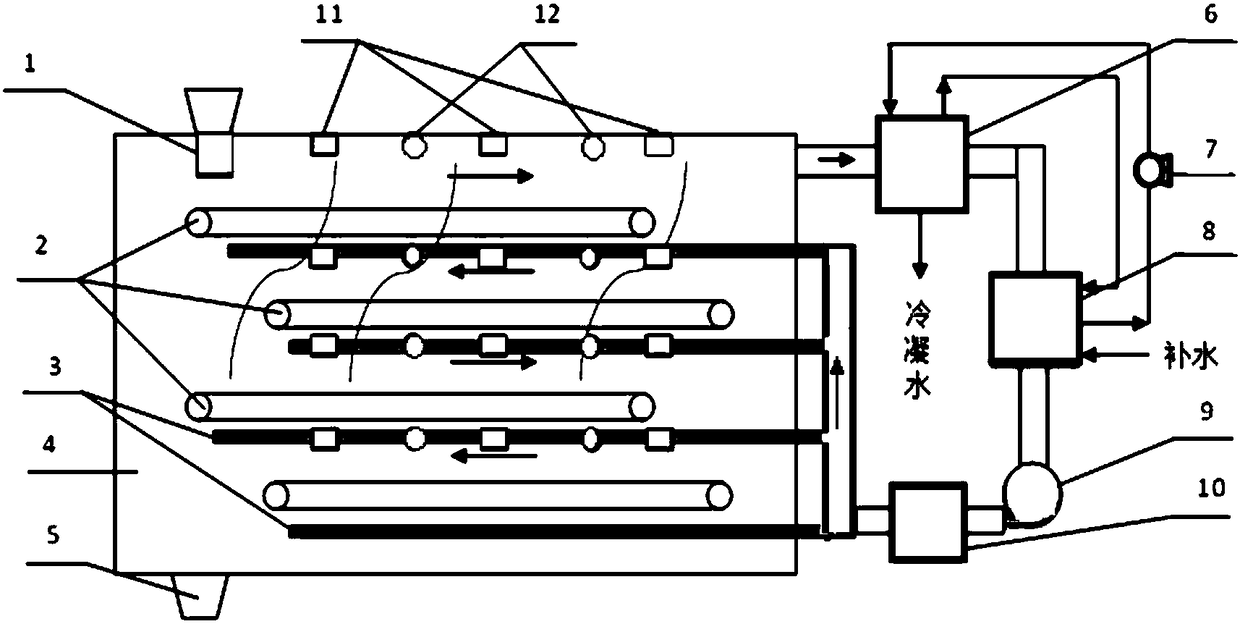

[0025] Please refer to Figure 1-2 , a sludge microwave infrared coupling low-temperature drying equipment provided by the present invention includes a screw conveyor, a sludge extrusion molding machine, a sludge preheater and a microwave infrared coupling drying device; the screw conveyor, sludge The mud extrusion molding machine, the sludge preheater and the microwave infrared coupling drying device are connected sequentially through pipelines; the microwave infrared coupling drying device includes a microwave infrared coupling drying machine, a first induced draft fan, a first heat exchanger, The second heat exchanger, heat pump, water circulation pump and electric heater, wherein the microwave infrared coupling dryer, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com