Pleura/meninges patch and preparation method thereof

A technology of meninges and pleura, applied in the field of pleura/meninges and its preparation, can solve the problems of incompatibility of biocompatibility and mechanical properties, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of pleura / meninges that the present invention proposes, comprises the following steps:

[0032] S1. According to the solid-liquid ratio of 1:100~5:100g / ml, the degree of deacetylation is greater than 60%, and the molecular weight is greater than 0.5×10 6 The squid cartilage chitosan or squid cartilage chitosan powder is dissolved into glue;

[0033] S2. After filtering the glue solution and degassing, spin coating to obtain pleura / meninges.

[0034] Wherein, the preparation of squid cartilage chitosan in step S1 comprises:

[0035] S11. Dissolve squid cartilage β-chitin or squid cartilage chitosan in a NaOH solution with a mass percent concentration of 30% to 40% according to a solid-liquid ratio of 5.0:100 to 25:100 g / ml, at 50 to 80 After stirring at ℃ for 1-6 hours, filter to obtain the filter residue;

[0036] S12, washing the filter residue obtained in step S11 until neutral and then drying to obtain squid cartilage chitosan used in ...

Embodiment 1

[0059] The present embodiment proposes a preparation method of pleura / meninges, comprising the following steps:

[0060] S1, 1.3g squid cartilage chitosan (DD=75%, MW=1.52×10 6 ) powder is dissolved in 100mL of acetic acid solution with a mass percentage concentration of 2%, and is configured into a glue;

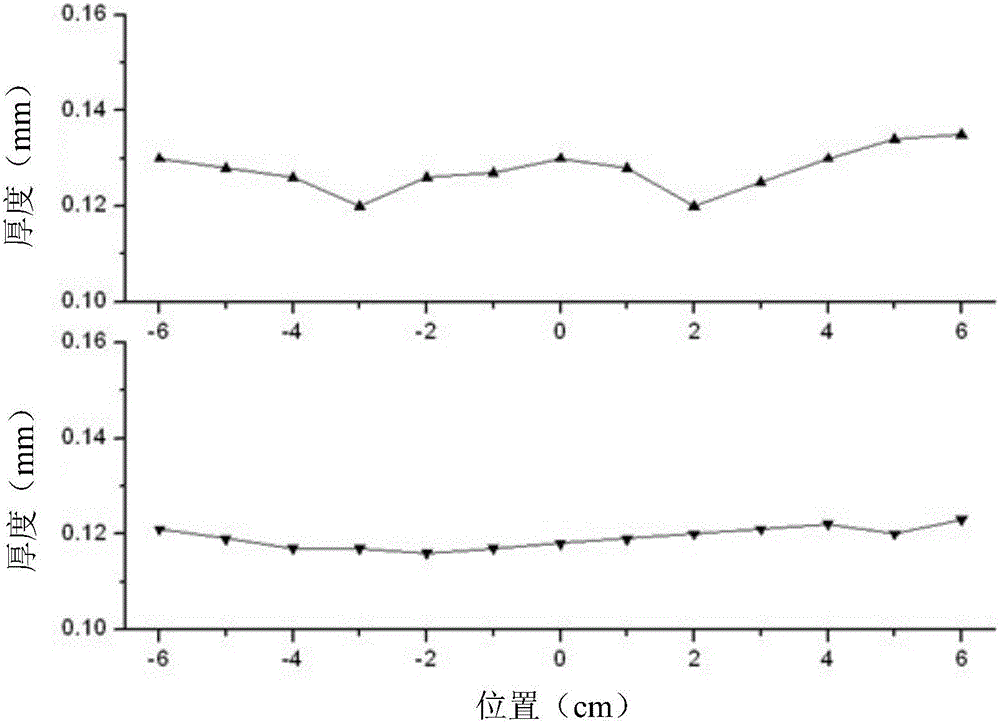

[0061] S2, spin-coating (r=2000rad / min, t=9s) through filtering, defoaming glue solution, obtains chitosan film;

[0062] S3. After drying the chitosan film in a blast drying oven at 60°C, wash it with dilute alkali solution and deionized water, and dry it again in a blast drying oven at 60°C to obtain a pleural / meningeal patch.

[0063] Wherein, the preparation of squid cartilage chitosan powder in step S1 comprises:

[0064] S11. According to the solid-liquid ratio of 10:100 (g / ml), the squid cartilage β-chitin was dissolved in a NaOH solution with a concentration of 35% by mass, stirred at 80° C. for 2 hours, and then filtered to obtain a filter residue;

[0065] S12....

Embodiment 2

[0073] The present embodiment proposes a preparation method of pleura / meninges, comprising the following steps:

[0074] S1, 1.5g squid cartilage chitosan (DD=95%, MW=1.15×10 6 ) powder is dissolved in 100mL of acetic acid solution with a mass percentage concentration of 2%, and is configured into a glue;

[0075] S2, spin-coating (r=2500rad / min, t=10s) through filtering, defoaming glue solution, obtains chitosan film;

[0076] S3. After drying the chitosan film in a blast drying oven at 60°C, wash it with dilute alkali solution and deionized water, and dry it again in a blast drying oven at 60°C to obtain a pleural / meningeal patch.

[0077] Wherein, the preparation of squid cartilage chitosan powder in step S1 comprises:

[0078] S11. The squid cartilage chitosan prepared in Example 1 (DD=75%, MW=1.52×10 6 ) powder was dissolved in NaOH solution with a concentration of 30% by mass, stirred at 50°C for 4 hours, and then filtered to obtain a filter residue;

[0079] S12. Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com