Preparation method of oxidized nano-cellulose/collagen composite sponge

A technology of collagen sponge and nanocellulose, which is applied in the field of biomedical composite materials, can solve the problems of poor mechanical properties of collagen, lack of cytotoxicity, and excessive degradation speed, and achieve improved physical and mechanical properties, decreased water absorption, The effect of reducing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

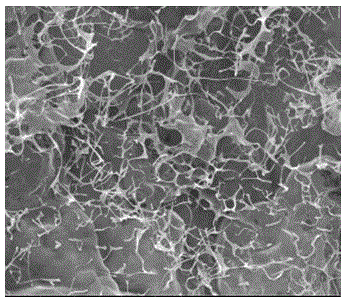

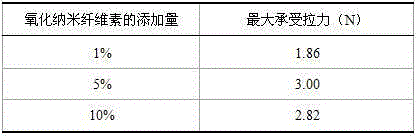

Image

Examples

specific Embodiment approach 1

[0035] Embodiment 1: This embodiment provides a method for preparing a collagen sponge, which is specifically carried out in accordance with the following steps:

[0036] Take the low-temperature frozen pure beef Achilles tendon, cut it into pieces, and put it in Na 2 CO 3 Soak in the solution for 6h, 12h, 24h, take it out and dry it and store it in low temperature freezer.

[0037] Put 5g of beef Achilles tendon mince into the acetic acid solution containing 4g of pepsin. Place the flask in a 4°C constant temperature water bath and stir slowly for 72 hours until the viscosity of the reaction solution does not change. Centrifuge in a high-speed refrigerated centrifuge for 30 minutes, and take the upper transparent viscous clear liquid to obtain the crudely extracted collagen stock solution.

[0038] Quickly add sodium chloride powder to the collagen solution and keep stirring with a glass rod. Salt out at 4°C, and a white massive precipitate precipitates out. Keep stirr...

specific Embodiment approach 2

[0041] Specific embodiment 2: This embodiment provides a method for preparing nanocellulose, specifically according to the following steps:

[0042] Put 2.0g of microcrystalline cellulose in 45ml of 50wt%, 60wt%, 64wt%, 70wt% sulfuric acid solution respectively, and magnetically stir, and react in a water bath at a temperature of 30°C, 40°C, and 50°C for 1h, 2h, 3h;

[0043] Pour the reaction solution into 450ml of deionized water to end the reaction, let it stand, and remove the supernatant; centrifuge and wash the suspension with deionized water for about 5 times, and measure the pH ≈ 7; after ultrasonic treatment for 30 minutes, put the sol into the dialysis bag ( MWCO 3000) for about 5 days to remove the remaining SO 4 2- ;

[0044] Pre-freeze the purified nanocrystalline cellulose at -10~-20°C for 24 hours, put it into a freeze dryer after pre-freezing, and treat it for 24 hours at a temperature of -56~-20°C and a vacuum of 10~40Pa. A white nanocellulose powder ...

specific Embodiment approach 3

[0045] Specific embodiment three: This embodiment provides a method for preparing oxidized nanocellulose, specifically according to the following steps:

[0046] ①Dissolve 0.1g, 0.5g, and 1.0g of the nanocellulose prepared in Embodiment 2 in 50mL of deionized water, and sonicate for 30min;

[0047] ②Use NaOH standard solution to adjust the pH to 10.8, add a certain amount of TEMPO and NaBr and mix evenly, control the mass ratio of nanocellulose, TEMPO and NaBr to 10:1:10, and take NaClO to adjust the pH to 10~11.8;

[0048] ③ After the reaction is completed, pour excess ethanol to terminate the reaction, centrifuge, remove the upper liquid, and wash with absolute ethanol for 5 times;

[0049] ④ Acidify with HCl solution for 3 hours, wash with ethanol for 5 times, dissolve in deionized water, pre-freeze at -10~-20°C for 24 hours, put it in a freeze dryer after pre-freezing, and store it at -56~- Under the conditions of 20°C and vacuum degree of 10-40Pa, treat for 24 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com