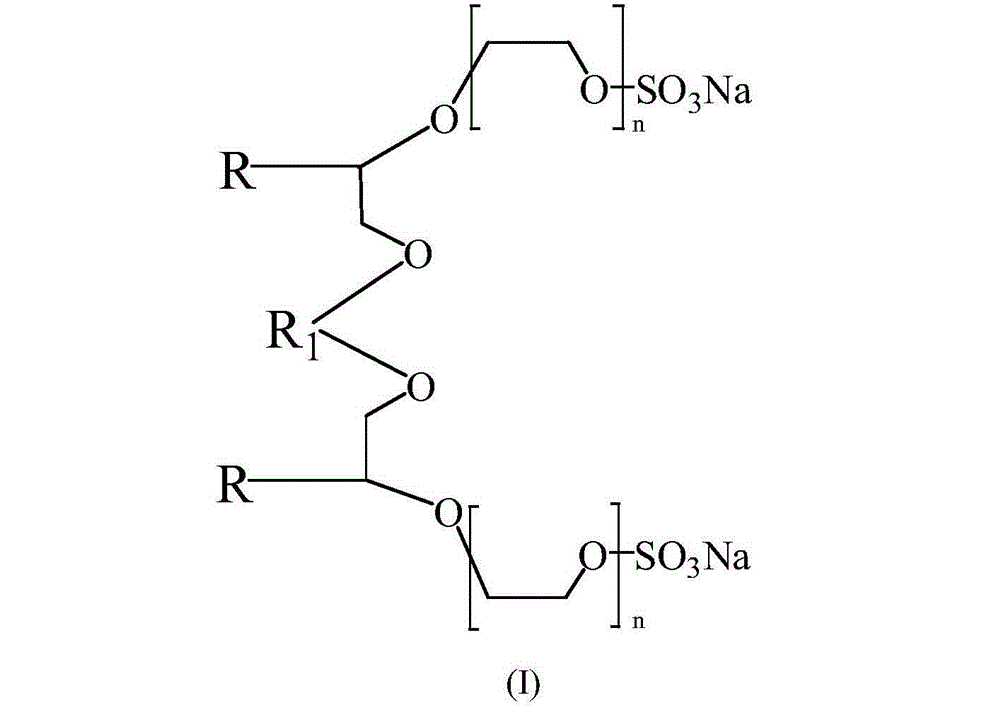

Gemini surfactant, preparation method and use method thereof

A surfactant and catalyst technology, which is applied in the preparation of sulfate esters, chemical instruments and methods, dehydration/demulsification by chemical methods, etc., can solve problems such as difficulty in applying oil displacement systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

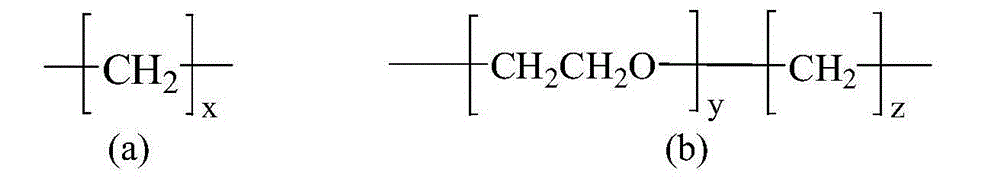

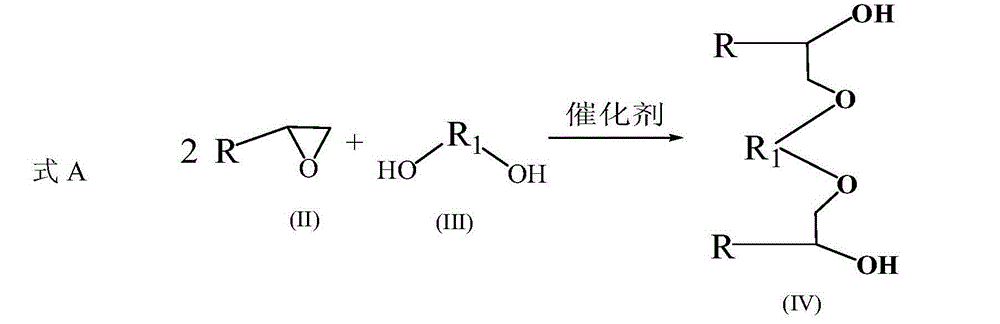

Method used

Image

Examples

Embodiment 1

[0053] Synthesis of sodium 1,8-di(dodecyl)-3,6-dioxa-1,8-octane disulfate:

[0054] a. Add NaH into the reactor with heating device, feed high-purity nitrogen gas at a uniform and gentle flow rate, and raise the temperature to 60°C under the protection of nitrogen atmosphere. Then ethylene glycol was added dropwise to the reactor under constant pressure, and the NaH was dissolved with continuous stirring. Continue to raise the temperature to 80°C, and then dropwise add 1,2-epoxytetradecane into the reactor at constant pressure. After the dropwise addition was completed, stir at constant temperature. After stirring the reaction for 45 hours, the heating was stopped. Slowly add 2 mol / L HCl aqueous solution to the system to stop the reaction.

[0055] Pour the reaction mixture into a separatory funnel, extract with dichloromethane / water (3×150mL / 150mL) system, combine the organic phases, dry with anhydrous sodium sulfate, and let stand overnight. Filter and evaporate the solv...

Embodiment 2

[0059] Synthesis of sodium 4,11-di(dodecyl)-3,6,9,12-tetraoxa-1,14-tetradecane disulfate:

[0060] a. Add NaH into the reactor with heating device, feed high-purity nitrogen gas at a uniform and gentle flow rate, and raise the temperature to 60°C under the protection of nitrogen atmosphere. Then ethylene glycol was added dropwise to the reactor under constant pressure, and the NaH was dissolved with continuous stirring. Continue to raise the temperature to 80°C, and then dropwise add 1,2-epoxytetradecane into the reactor at constant pressure.

[0061] After the dropwise addition was completed, stir at constant temperature. After stirring the reaction for 45 hours, the heating was stopped. Slowly add 2 mol / L HCl aqueous solution to the system to stop the reaction.

[0062] Pour the reaction mixture into a separatory funnel, extract with dichloromethane / water (3×150mL / 150mL) system, combine the organic phases, dry with anhydrous sodium sulfate, and let stand overnight. Filte...

Embodiment 3

[0066] Synthesis of 7,14-di(dodecyl)-3,6,9,12,15,18-hexaoxa-1,20-eicosane disulfate sodium:

[0067] a. Add NaH into the reactor with heating device, feed high-purity nitrogen gas at a uniform and gentle flow rate, and raise the temperature to 60°C under the protection of nitrogen atmosphere. Then ethylene glycol was added dropwise to the reactor under constant pressure, and the NaH was dissolved with continuous stirring. Continue to raise the temperature to 80°C, and then dropwise add 1,2-epoxytetradecane into the reactor at constant pressure. After the dropwise addition was completed, stir at constant temperature. After stirring the reaction for 45 hours, the heating was stopped. Slowly add 2 mol / L HCl aqueous solution to the system to stop the reaction.

[0068]Pour the reaction mixture into a separatory funnel, extract with dichloromethane / water (3×150mL / 150mL) system, combine the organic phases, dry with anhydrous sodium sulfate, and let stand overnight. Filter and ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com