Method for rapidly preparing nano-silver particles

A technology of nano silver particles and silver nitrate, applied in the field of nano materials, can solve the problems of long reaction time, difficult to control particle size, long synthesis time, etc., and achieve the effects of good dispersibility, good stability and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 0.2g of collagen hydrolyzate in 10mL of distilled water, fully swell, heat up to 60°C, stop heating after the dissolution is complete, and prepare an aqueous solution of collagen hydrolyzate;

[0024] (2) Dissolve 0.176g of ascorbic acid in 10mL of distilled water to prepare ascorbic acid solution, and adjust the pH value of the solution to 7 with ammonia water;

[0025] (3) Under magnetic stirring conditions, 10 mL of ascorbic acid solution was added dropwise to 10 mL of collagen hydrolyzate solution dissolved with silver nitrate, and stirring reaction was continued for 15 minutes after the addition was completed, and the reaction temperature was room temperature;

[0026] (4) In the prepared solution containing silver nanoparticles, take 0.5mL in a vial, then add 0.5ml of distilled water, then take 2mg of porous carbon into it, mix, and disperse evenly by ultrasonic. Collagen hydrolyzate / nano-silver / porous carbon composite was prepared;

[0027] (5) Take 10 ...

Embodiment 2

[0029] (1) Take 0.2g of collagen hydrolyzate in 10mL of distilled water, fully swell, heat up to 60°C, stop heating after the dissolution is complete, and prepare an aqueous solution of collagen hydrolyzate;

[0030] (2) Dissolve 0.176g of ascorbic acid in 10mL of distilled water to prepare ascorbic acid solution, and adjust the pH value of the solution to 11 with ammonia water;

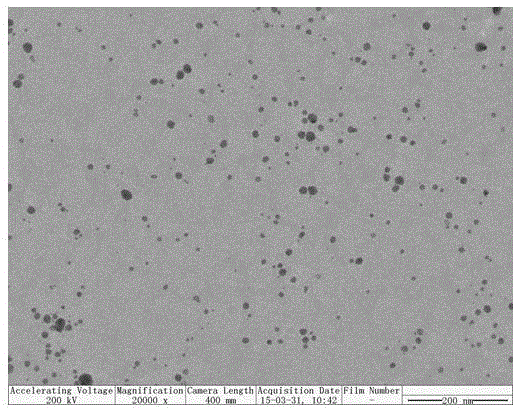

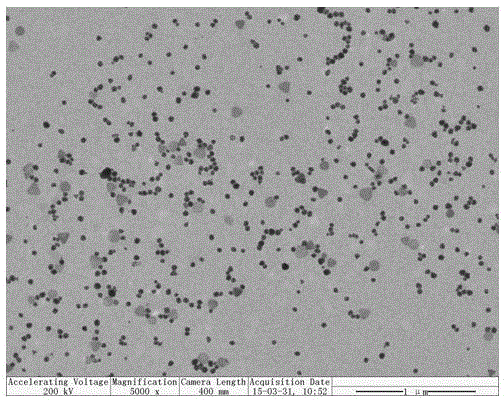

[0031] (3) under magnetic stirring condition, 10mL ascorbic acid solution is added dropwise in the collagen protein hydrolyzate solution that is dissolved with silver nitrate 10mL, continues to stir reaction 15 minutes after dropwise addition finishes, and reaction temperature is room temperature, prepares nano-silver particle, the result Such as figure 1 shown;

[0032] (4) In the prepared solution containing silver nanoparticles, take 0.5mL in a vial, then add 0.5mL of distilled water, then take 2mg of porous carbon into it, mix, and disperse uniformly by ultrasonic. Collagen hydrolyzate / nano-sil...

Embodiment 3

[0035] (1) Take 0.2g of collagen hydrolyzate in 10mL of distilled water, fully swell, heat up to 60°C, stop heating after the dissolution is complete, and prepare an aqueous solution of collagen hydrolyzate;

[0036] (2) Dissolve 0.176g of ascorbic acid in 10mL of distilled water to prepare ascorbic acid solution, and adjust the pH value of the solution to 7 with ammonia water;

[0037] (3) Under the condition of magnetic stirring, add 10 mL of ascorbic acid solution dropwise into 10 mL of collagen hydrolyzate solution dissolved in silver nitrate, and continue stirring and reacting for 15 minutes after the dropping, and the reaction temperature is 40° C.;

[0038] (4) In the prepared solution containing silver nanoparticles, take 0.5mL in a vial, then add 0.5mL of distilled water, then take 2mg of porous carbon into it, mix, and disperse uniformly by ultrasonic. Collagen hydrolyzate / nano-silver / porous carbon composite was prepared;

[0039] (5) Take 10 μL of the prepared coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com