Environment-friendly high-barrier multi-layer coextrusion medical transfusion film

An environment-friendly, high-barrier technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of PCCE copolyester ether that have not been seen yet, and achieve good transparency and uniform microstructure , Excellent heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

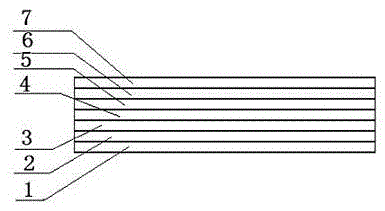

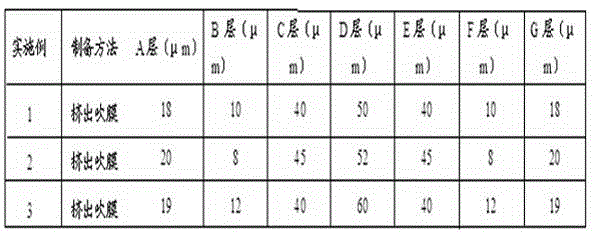

[0026] Example 1, such as figure 1As shown, an environment-friendly high-barrier multi-layer co-extrusion medical infusion film, the medical infusion film adopts a seven-layer film composite structure, and the layers are A / B / C / D / E / F / G from outside to inside. : The A layer is the outer layer 2, and the material is a copolymer formed by the copolymerization of 1,4-cyclohexanedicarboxylic acid, 1,4-cyclohexanedimethanol and poly-1,4-butanediol Ester ether PCCE and polyethylene naphthalate reaction blended esterified resin; B layer is the first adhesive layer (2), the material is ethylene methacrylate copolymer; C layer is the sub-core layer 3 , the material is metallocene linear polyethylene; the D layer is the core layer 4, and the material is high temperature resistant ethylene-vinyl alcohol copolymer; the E layer is the sub-core layer 5, and the material is metallocene linear polyethylene; the F layer is the second adhesive Layer 6, the material is metallocene linear polyethy...

Embodiment 2

[0027] In Example 2, the thickness of each layer of A / B / C / D / E / F / G is 20 μm, 8 μm, 45 μm, 52 μm, 45 μm, 8 μm, and 20 μm in sequence, and the rest are the same as in Example 1.

Embodiment 3

[0028] In Example 3, the thicknesses of the layers of A / B / C / D / E / F / G are 19 μm, 12 μm, 40 μm, 60 μm, 40 μm, 12 μm, and 19 μm, and the rest are the same as in Example 1.

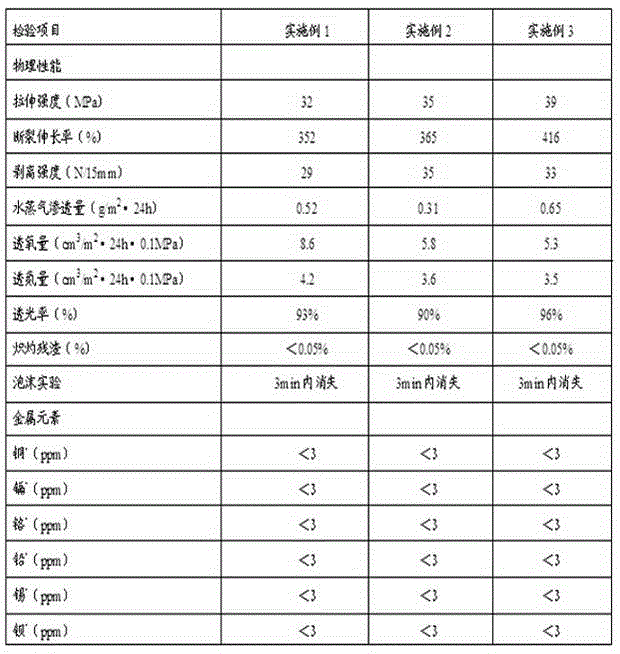

[0029] For three specific examples, see figure 2 , a table of specific embodiments of the present invention. Except that the material of layer A is self-made by reaction blending, other materials used in the present invention are purchased from the market, and all production and preparation processes are carried out in a clean area of 10,000 grades, and the seven-layer co-extruded medical infusion film is purified in nitrogen or argon gas of 10,000 grades. Under air conditions, it is produced by seven-layer co-extrusion blown film technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com