Saline-alkali soil improver prepared from ardealite and cane trash, as well as preparation method and application of saline-alkali soil improver

A technology of bagasse and phosphogypsum, applied in application, fertilizer mixture, fertilization device, etc., can solve the problems of high cost and low soil pH adjustment ability, and achieve the effect of increasing adsorption capacity, enhancing effect, and preventing crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

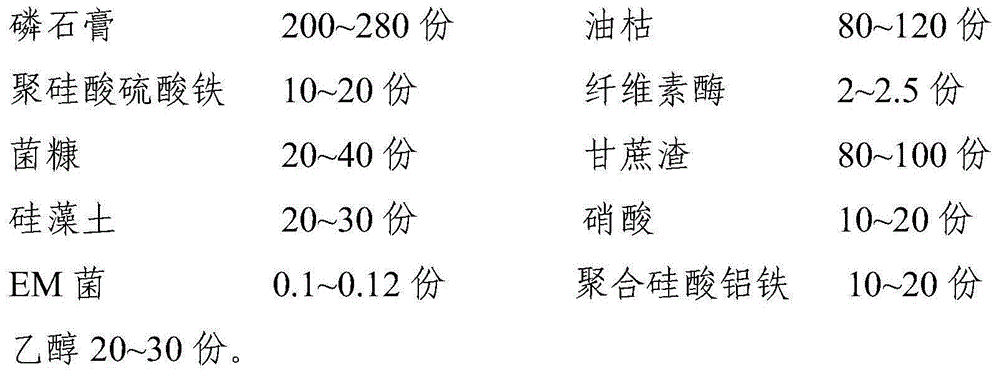

[0035] raw material:

[0036] Phosphogypsum 200kg, oil dry 80kg, polysilicate iron sulfate 10kg, cellulase 2kg, fungus chaff 20kg, bagasse 80kg, diatomite 20kg, nitric acid 10kg, EM bacteria 0.1kg, polyaluminum iron silicate 10kg and ethanol 20kg .

[0037] Preparation:

[0038] (1) Phosphogypsum and diatomite pretreatment: drying the phosphogypsum and diatomite to a moisture content of 5% respectively, and then pulverizing them into 60-mesh fine powder to obtain phosphogypsum powder and diatomite powder;

[0039] (2) Bagasse pretreatment: put the bagasse into the autoclave, and add ethanol and water with a concentration of 20%. After 60 minutes, filter the filter residue, mix the filter residue with 10% nitric acid, add water to adjust the pH value to 5.5, add cellulase for enzymolysis, the temperature of the enzymolysis is controlled at 55°C, and the enzymolysis time is 8 hours , drying the material obtained by enzymatic hydrolysis to a moisture content of 5% at a tempera...

Embodiment 2

[0044] raw material:

[0045] Phosphogypsum 280kg, oil dry 120kg, polysilicate ferric sulfate 20kg, cellulase 2.5kg, fungus chaff 40kg, bagasse 100kg, diatomite 30kg, nitric acid 20kg, EM bacteria 0.12kg, polyaluminum iron silicate 20kg and ethanol 30kg.

[0046] Preparation:

[0047] (1) Phosphogypsum and diatomite pretreatment: drying the phosphogypsum and diatomite to a moisture content of 10% respectively, and then pulverizing them into 200-mesh fine powder to obtain phosphogypsum powder and diatomite powder;

[0048] (2) Bagasse pretreatment: send the bagasse into the autoclave, and add ethanol and water with a concentration of 40%. After 80 minutes, filter the filter residue, mix the filter residue with 30% nitric acid, add water to adjust the pH value to 5, add cellulase for enzymolysis, the temperature of the enzymolysis is controlled at 60°C, and the enzymolysis time is 10 hours , drying the material obtained by enzymatic hydrolysis to a moisture content of 7% at a...

Embodiment 3

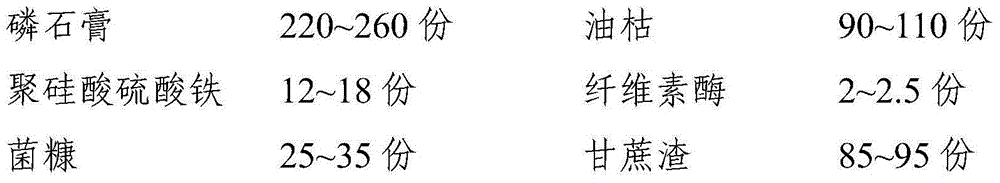

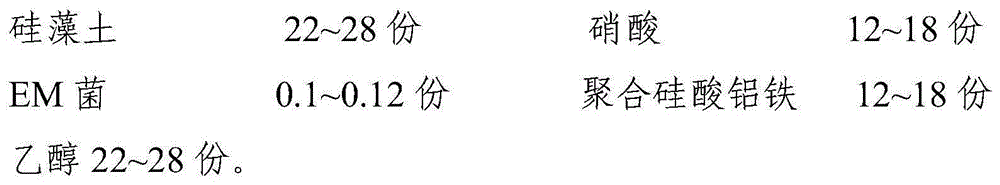

[0053] raw material:

[0054] Phosphogypsum 240kg, oil dry 100kg, polysilicate ferric sulfate 15kg, cellulase 2.2kg, fungus chaff 30kg, bagasse 90kg, diatomite 15kg, nitric acid 15kg, EM bacteria 0.11kg, polyaluminum iron silicate 15kg and ethanol 25kg.

[0055] Preparation:

[0056] (1) Phosphogypsum and diatomite pretreatment: drying the phosphogypsum and diatomite to a moisture content of 8% respectively, and then pulverizing them into 80-mesh fine powder to obtain phosphogypsum powder and diatomite powder;

[0057] (2) Bagasse pretreatment: put the bagasse into the autoclave, and add ethanol and water with a concentration of 30%. After 70 minutes, filter the filter residue, mix the filter residue with 20% nitric acid, add water to adjust the pH value to 5.2, add cellulase for enzymolysis, the temperature of the enzymolysis is controlled at 57°C, and the enzymolysis time is 9h , drying the material obtained by enzymatic hydrolysis to a moisture content of 6% at a tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com