Method for preparing polysaccharide-rich extract from papaya seed coat

A polysaccharide extraction and papaya seed technology is applied in the field of preparation of the papaya seed coat rich in polysaccharide extract, can solve the problems of application, and there is no preparation method for the papaya seed coat, and achieves wide application, low equipment investment and mild extraction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

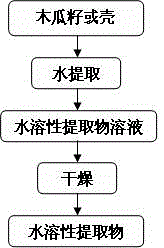

Image

Examples

Embodiment 1

[0024] Example 1: Extraction of papaya seed coat rich in polysaccharide extract under acidic conditions at room temperature

[0025] Take 200g of papaya seeds, adjust the pH value of the water to 3 by adding sulfuric acid, add 200g of papaya seeds into 1000mL of water with adjusted pH value, stir at room temperature (25°C) at 500 rpm for 10min, filter the aqueous solution, and filter Add papaya seeds into 1000mL water with a pH value of 3, stir at 500 rpm for 10min, then filter to obtain an aqueous solution, collect it and combine it with the aqueous solution obtained from the first extraction, repeat the above steps of extraction and filtration twice, and finally collect the water-soluble extract 4000mL, freeze-dry the obtained water-soluble extract at a temperature of -55°C and a pressure of -0.04Mpa to obtain 12g of the polysaccharide-rich extract of the papaya seed coat, and the yield of the polysaccharide-rich extract of the papaya seed coat is based on 200g of papaya seed...

Embodiment 2

[0026] Example 2: Extraction of Papaya Seed Coat Rich in Polysaccharide Extract under High Temperature and Alkaline Conditions

[0027] Take 50g of papaya seed peel, the pH of the aqueous solution is controlled at 12 by sodium hydroxide, add 50g of papaya seed peel to 500mL of water with adjusted pH value, heat on a magnetic heating stirrer until the temperature is 120 degrees, and stir at 1000 rpm for 10min , filtered to obtain an aqueous solution, and repeated the above extraction and separation process 3 times to obtain a 2000mL water-soluble extract solution. The aqueous solution was dried and processed at 105°C under normal pressure to obtain 2.6g of the final product papaya seed coat-rich polysaccharide extract. The yield of papaya seed coat rich in polysaccharide extract was 5.2%.

Embodiment 3

[0028] Example 3: Extraction of papaya seed coat rich in polysaccharide extract under neutral conditions at room temperature

[0029] Take 100g of papaya seeds, add 500mL of water without adjusting the pH value, stir at room temperature (25°C) at 1000 rpm for 5 minutes, then stop, separate the water-soluble extract, filter and separate the obtained papaya seeds, and repeat the above extraction and separation steps Three times, the obtained water-soluble extract solution was collected and dried at a temperature of -55°C and a pressure of -0.04Mpa to obtain 6.5g of a water-soluble extract of papaya seed coat, with a yield of 6.5% based on papaya seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com