A kind of preparation method of sulfonated polyimide proton conductive membrane containing branched structure

A technology of sulfonated polyimide membrane and sulfonated polyimide, which is applied to structural parts, circuits, electrical components, etc., can solve the problems of shortening the service life of batteries, poor anti-oxidation ability of separators, and decreasing battery capacity, etc. To achieve the effect of improving anti-oxidation, improving anti-oxidative ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

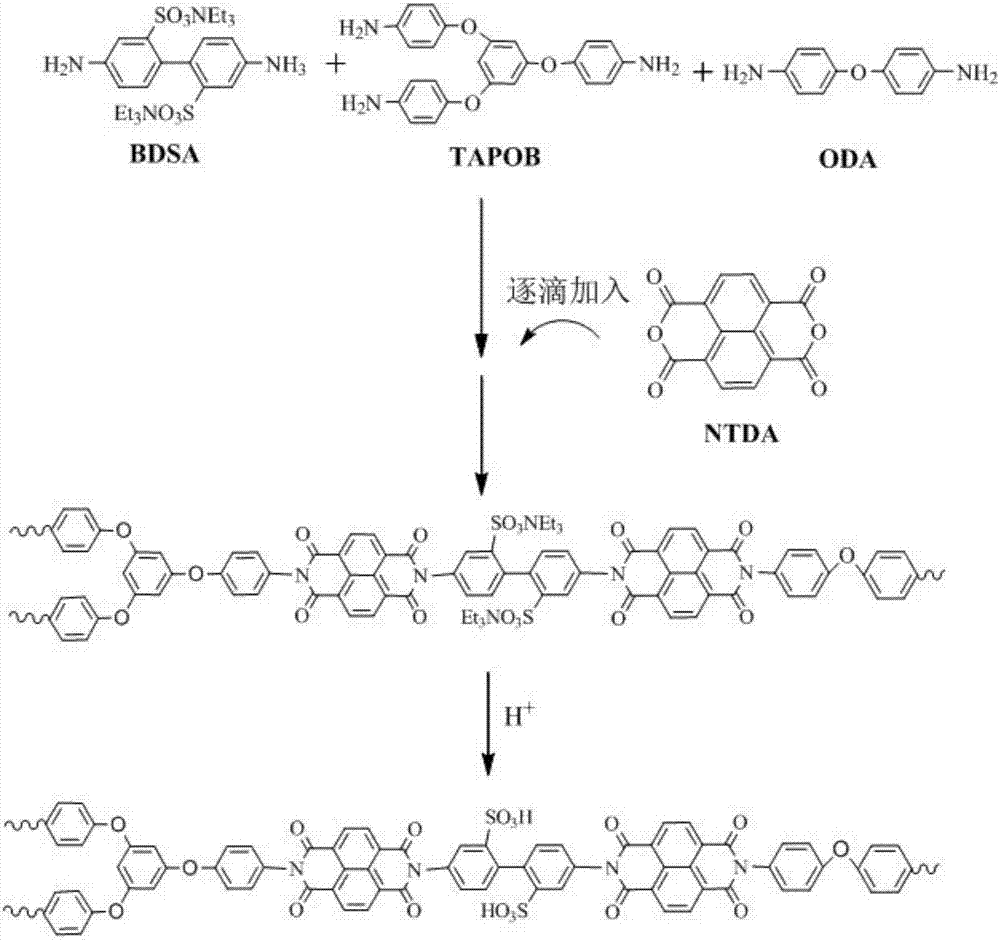

Method used

Image

Examples

Embodiment 1

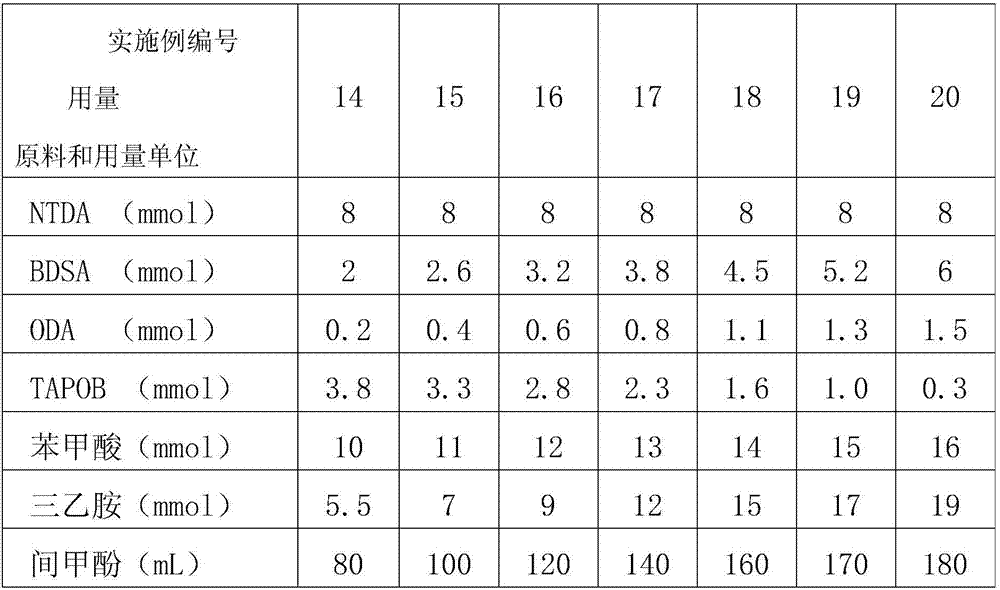

[0024] in N 2 Under protection, add 2.0mmol BDSA, 50mL m-cresol, 5.0mmol triethylamine into a 250mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, then add 1.0mmol ODA and 3.3mmol TAPOB into the container until completely dissolved; Dissolve 8.0mmol NTDA and 1.2g benzoic acid in 20ml m-cresol, place in a constant pressure dropping funnel and add slowly dropwise, and raise the temperature to 50°C for 15 hours, put the reaction solution in a clean glass The film is cast on the board, and then dried at a temperature of 60-150°C (for thermal imidization), and the branched sulfonated polyimide film of the triethylamine salt type is obtained;

[0025] The branched sulfonated polyimide membrane of the prepared triethylamine salt type was placed in acetone and soaked for 10 hours to remove excess solvent and non-participating reactants, and then soaked in 1.0mol / L sulfuric acid solution for 20 hours to make It is completely protonated, and...

Embodiment 2

[0029] in N 2 Under protection, add 3.0mmol BDSA, 60mL m-cresol, 5.0mmol triethylamine into a 250mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, then add 1.0mmol ODA and 2.67mmol TAPOB into the container until completely dissolved; Dissolve 8.0mmol NTDA and 1.2g of benzoic acid in 30ml of m-cresol, and place in a constant pressure dropping funnel to slowly add dropwise, and raise the temperature to 50°C for 20 hours, and put the reaction solution in a clean glass The film is cast on the board, and then dried at a temperature of 60-150 ° C (for thermal imidization), that is, a triethylamine salt-type branched sulfonated polyimide film is obtained;

[0030] The branched sulfonated polyimide membrane of the prepared triethylamine salt type was placed in acetone and soaked for 24 hours to remove excess solvent and non-participating reactants, and then soaked in 1.0mol / L sulfuric acid solution for 24 hours to make It is completely pro...

Embodiment 3

[0034] in N 2 Under protection, add 4.0mmol BDSA, 70mL m-cresol, 5.0mmol triethylamine into a 250mL three-neck flask, stir continuously at room temperature until BDSA is completely dissolved, then add 2.0mmol ODA and 1.33mmol TAPOB into the container until completely dissolved; Dissolve 8.0mmol NTDA and 1.8g of benzoic acid in 30ml of m-cresol, and place it in a constant pressure dropping funnel and add it slowly, and raise the temperature to 50°C for 20 hours. Put the reaction solution on a clean glass The film is cast on the board, and then dried at a temperature of 60-150°C (for thermal imidization), and the branched sulfonated polyimide film of the triethylamine salt type is obtained;

[0035] The branched sulfonated polyimide membrane of the prepared triethylamine salt type was placed in acetone and soaked for 30 hours to remove excess solvent and non-participating reactants, and then soaked in 2.0mol / L sulfuric acid solution for 12 hours to make It is completely protona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com