Preparation method of sulfonated polyimide/titanium dioxide composite proton conductive membrane

A technology of sulfonated polyimide and proton conductive membrane, which is applied in the field of battery diaphragm preparation, can solve the problems affecting the long-term service life of the battery, the poor anti-oxidation ability of the diaphragm, and the decrease of battery capacity, etc., and achieves good application prospects, superior chemical , Excellent effect of open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

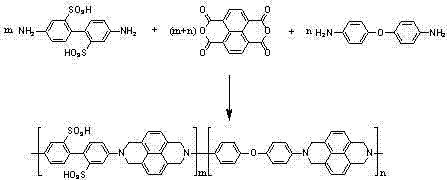

Method used

Image

Examples

Embodiment 1

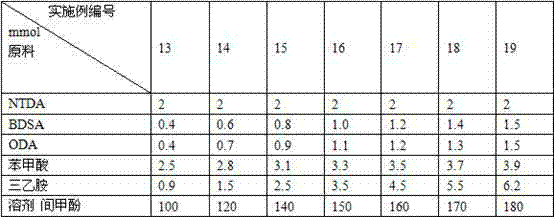

[0026] A preparation method of sulfonated polyimide / titanium dioxide composite proton conductive membrane:

[0027] Under N2 protection, 1.0 mmol BDSA, 10 mL m-cresol, 2.0 mmol triethylamine were added to a 100 mL three-necked flask, and stirred continuously at room temperature until BDSA was completely dissolved, then 2.0 mmol NTDA, 0.49 g benzoic acid and 1.0 mmol ODA were added, After continuing to stir for a few minutes, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature drops below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue stirring for a few minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone for several times to remove the residual solvent and unreacted substances, and then dried at 80°C for 20 hours;

[0028]Dissolve the obtai...

Embodiment 2

[0032] A preparation method of sulfonated polyimide / titanium dioxide composite proton conductive membrane:

[0033] Under the protection of N2, add 1.2 mmol BDSA, 10 mL m-cresol, 2.4 mmol triethylamine to a 100 mL three-necked flask, stir continuously at room temperature until BDSA is completely dissolved, add 2.0 mmol NTDA, 0.49 g benzoic acid and 0.8 mmol ODA, After continuing to stir for a few minutes, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature drops below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue stirring for a few minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone for several times to remove the residual solvent and unreacted substances, and then dried at 80°C for 20 hours;

[0034] Dissolve the obtained triethylamine s...

Embodiment 3

[0038] A preparation method of sulfonated polyimide / titanium dioxide composite proton conductive membrane:

[0039] Under N2 protection, add 1.0 mmol BDSA, 10 mL m-cresol, 2.0 mmol triethylamine to a 100 mL three-necked flask, stir continuously at room temperature until BDSA is completely dissolved, add 2.0 mmol NTDA, 0.49 g benzoic acid and 1.0 mmol ODA, continue After stirring for a few minutes, the temperature of the system was raised to 80 °C for 4 hours, and then to 180 °C for 20 hours, and the heating was stopped to obtain a viscous polymer solution. When the temperature drops below 80 °C, add 5 mL of m-cresol to dilute the reaction solution, continue to stir for a few minutes, then pour acetone into it to obtain a flocculent polymer precipitate, filter it, and wash the precipitate repeatedly with acetone several times to remove the residual solvent and unreacted substances, and then dried at 80°C for 25 hours;

[0040] The sulfonated polyimide of the obtained triethyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com