Hot-melting phenolic resin prepreg and preparation method thereof

A technology of phenolic resin and hot melt method, which is applied in the field of prepreg manufacturing, can solve the problems of unresearched and little research, and achieve the effects of low curing speed, strong practicability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

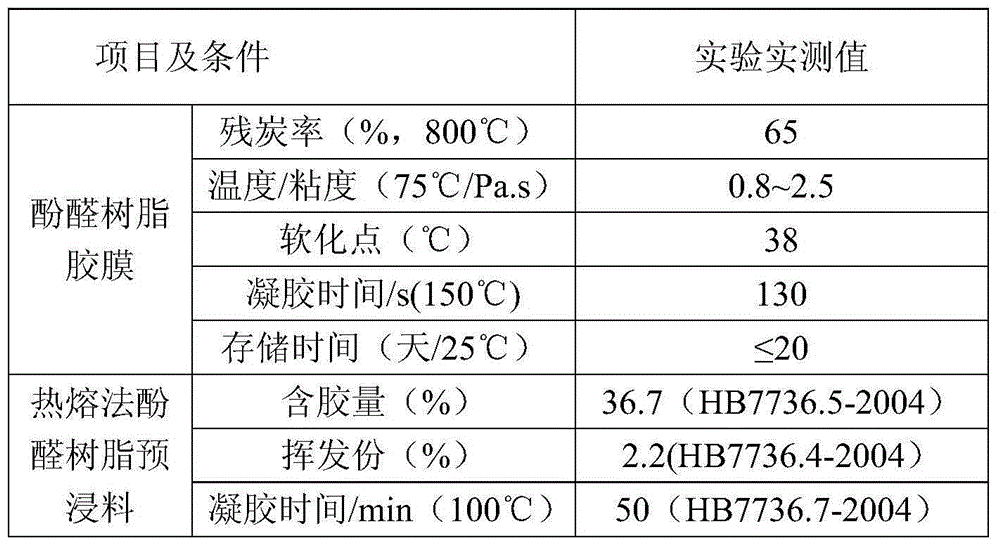

Embodiment 1

[0028] The preparation method of hot-melt method phenolic resin prepreg of the present invention comprises the following steps:

[0029] 1) Weigh high-strength glass fiber woven plain glass cloth, barium phenolic resin, acrylic polyurethane and inorganic boron compound boric acid, add barium phenolic resin into the reaction bottle, and heat to 65 ° C to melt the barium phenolic resin, wherein, after heating Add acrylic polyurethane and inorganic boron compound boric acid during the process, and then stir at constant temperature for 120 minutes, so that the rotating speed of the barium phenolic resin in the reaction bottle is 400 rpm to obtain a phenolic resin mixture, and then freeze and store the phenolic resin mixture, wherein the barium phenolic resin The mass parts of resin, acrylic polyurethane and inorganic boron compound boric acid are 100 parts, 4 parts and 4.5 parts respectively, and the mass ratio of the plain glass cloth of high-strength glass fiber weaving and bariu...

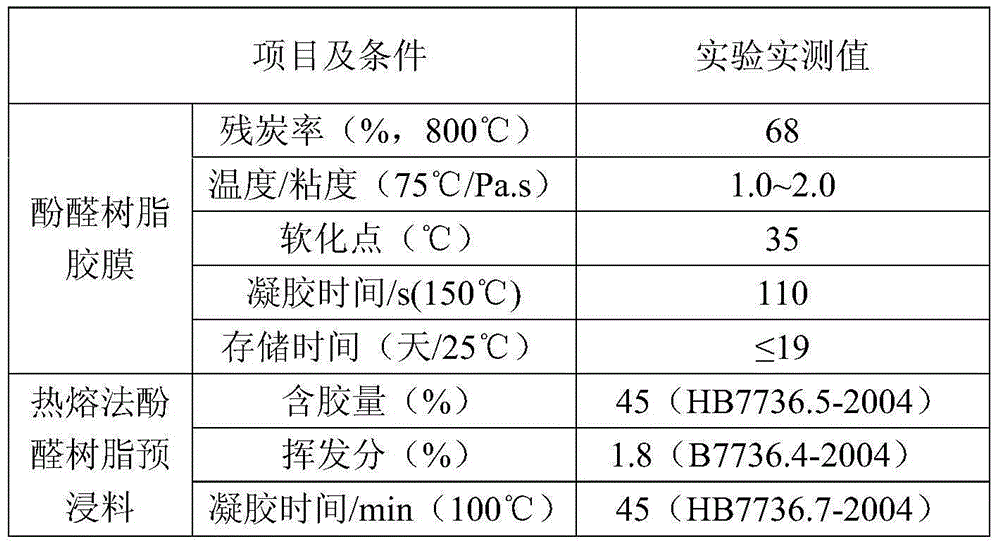

Embodiment 2

[0033] The preparation method of hot-melt method phenolic resin prepreg of the present invention comprises the following steps:

[0034] 1) Weigh plain carbon cloth woven with carbon fibers, barium phenolic resin, polyether polyurethane and carboxyphenylboronic acid, add barium phenolic resin to the reaction bottle, and heat to 65°C to melt the molybdenum phenolic resin. Add polyether polyurethane and carboxyl phenylboronic acid, and then stir at constant temperature for 90 minutes, so that the rotating speed of the barium phenolic resin in the reaction bottle is 380 rpm to obtain a phenolic resin mixture, and then freeze and store the phenolic resin mixture, wherein the barium phenolic resin The mass parts of resin, polyether type polyurethane and carboxyl-containing phenylboronic acid are 100 parts, 8 parts and 6.5 parts respectively, and the mass ratio of the plain weave carbon cloth of carbon fiber weaving and barium phenolic resin is 1:1;

[0035]2) Place the phenolic res...

Embodiment 3

[0038] The preparation method of hot-melt method phenolic resin prepreg of the present invention comprises the following steps:

[0039] 1) Weigh the plain weave glass cloth woven by aromatic polyamide fiber, tungsten phenolic resin, polyester polyurethane and boron oxide, add the tungsten phenolic resin into the reaction bottle, and heat to 60°C to melt the tungsten phenolic resin, wherein, Add polyester polyurethane and boron oxide during the heating process, and then stir at constant temperature for 80 minutes, so that the rotating speed of the tungsten phenolic resin in the reaction bottle is 100 rpm to obtain a phenolic resin mixture, and then freeze and store the phenolic resin mixture, wherein, The mass parts of tungsten phenolic resin, polyester polyurethane and boron oxide are 50 parts, 1 part and 1 part respectively, and the mass ratio of plain weave glass cloth woven by aramid fiber and tungsten phenolic resin is 1:1;

[0040] 2) Place the phenolic resin mixture obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com