Anticorrosive coating used on inner wall of desulfurization and denitrification device and preparation method thereof

A technology for desulfurization, denitrification, and anti-corrosion coatings, applied in the field of coatings, can solve the problems of no anti-corrosion coatings, smoke and dust erosion and wear, achieve good penetration resistance, improve corrosion resistance, and solve high-temperature corrosion and serious effects of smoke and dust erosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

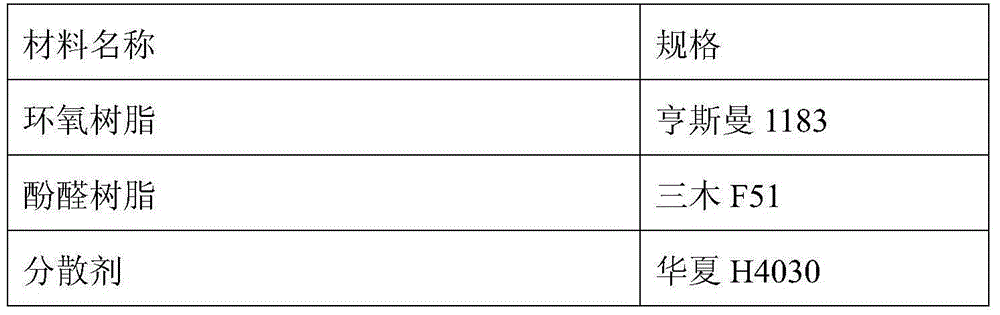

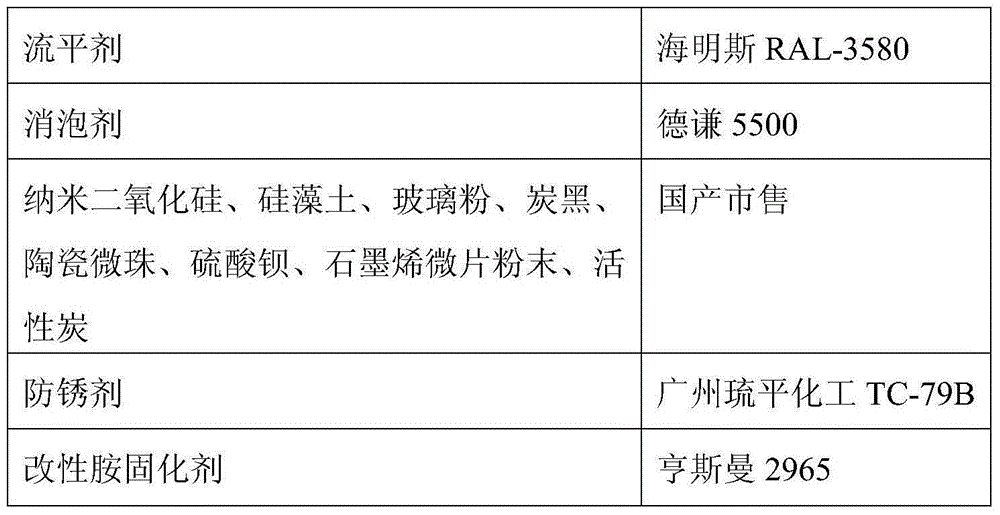

[0033] Embodiments 1 to 3: The preparation method of the anti-corrosion coating for the inner wall of the desulfurization and denitrification device provided by the present invention, the specific steps are as follows:

[0034] 1. Preparation of main paint component A:

[0035] (1) Take by weighing 1# solvent, epoxy resin, phenolic resin, drop in the reactor, start mixer, control rotating speed at 400 rpm;

[0036] (2) Add dispersant, carbon black, and nano-silica in turn, and stir for 20 minutes at a speed of 600 rpm. After stirring evenly, grind to a fineness below 25um;

[0037] (3) Stir the milled paint slurry at a speed of 600 rpm for 20 minutes, add defoamer and leveling agent under stirring, and after stirring evenly, add diatomite, glass powder, ceramic micropowder, sulfuric acid in turn Barium, antirust agent, graphene microflake powder, activated carbon, keep stirring at a speed of 9000 rpm for about 30 minutes until there are no obvious particles;

[0038] 2. Prep...

Embodiment 4

[0043] Embodiment 4: The preparation method of the anti-corrosion coating for the inner wall of the desulfurization and denitrification device provided by the present invention, its specific steps are as follows:

[0044] 1. Preparation of main paint component A:

[0045] (1) take by weighing 1# solvent, epoxy resin, phenolic resin, drop in the reactor, start mixer, control rotating speed at 500 rpm;

[0046] (2) Then add dispersant, carbon black, and nano-silica in sequence, and stir at a speed of 800 rpm for 15 to 30 minutes. After stirring evenly, grind to a fineness below 25um;

[0047] (3) Stir the milled paint slurry at a speed of 800 rpm for 15 minutes, add defoamer and leveling agent under stirring, and after stirring evenly, add diatomite, glass powder, ceramic micropowder, sulfuric acid in turn Barium, antirust agent, graphene microflake powder, activated carbon, keep stirring at 1000 rpm for about 20 minutes until there are no obvious particles;

[0048] 2. Prepar...

Embodiment 5

[0053] Embodiment 5: The preparation method of the anti-corrosion coating for the inner wall of the desulfurization and denitrification device provided by the present invention, its specific steps are as follows:

[0054] 1. Preparation of main paint component A:

[0055] (1) take by weighing 1# solvent, epoxy resin, phenolic resin, drop in the reactor, start mixer, control rotating speed at 300 rpm;

[0056] (2) Add dispersant, carbon black, and nano-silica in turn, and stir for 30 minutes at a speed of 500 rpm. After stirring evenly, grind to a fineness below 25um;

[0057] (3) Stir the milled paint slurry at a speed of 500 rpm for 30 minutes, add defoamer and leveling agent under stirring, and after stirring evenly, add diatomite, glass powder, ceramic micropowder, sulfuric acid in turn Barium, antirust agent, graphene microflake powder, activated carbon, keep stirring at 800 rpm for about 40 minutes until there are no obvious particles;

[0058] 2. Preparation of curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com