a gasoline additive

A technology of gasoline additives and additives, applied in the field of gasoline additives, to achieve the effects of prolonging efficiency, improving combustion performance, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

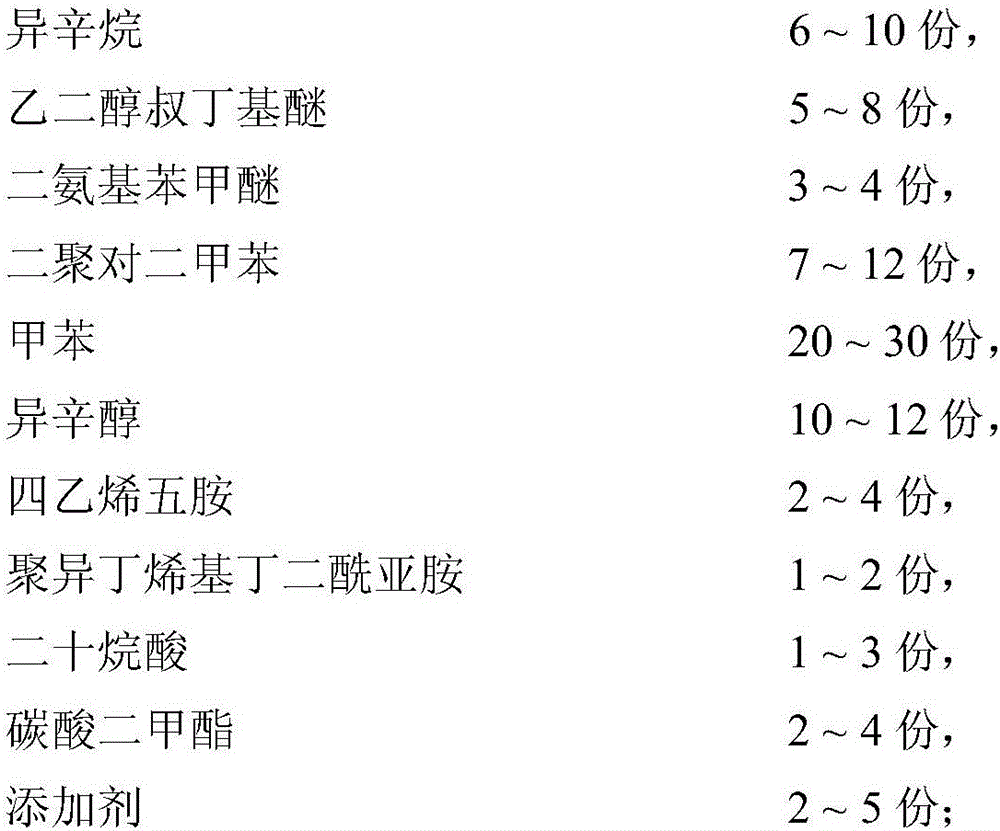

[0025] The gasoline additive in the present embodiment comprises the following components by weight:

[0026]

[0027]

[0028] Wherein, the additive is a mixture of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst, and the mass ratio of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst in the mixture is 1 :4:6:1.

[0029] The preparation process of above-mentioned catalyst is as follows:

[0030] (a) Add 1 mass part of cerium ammonium nitrate to 10 mass parts of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution A; 2 mass parts of dibenzoylmethane Add to 10 parts by mass of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution B; add 0.3 parts by mass of sodium hydroxide to 10 parts by mass of deionized water to prepare solution C ;

[0031] (b) At room temperature, add solution B dropwise to solution C to generate a white suspension. After the dropwise addition, c...

Embodiment 2

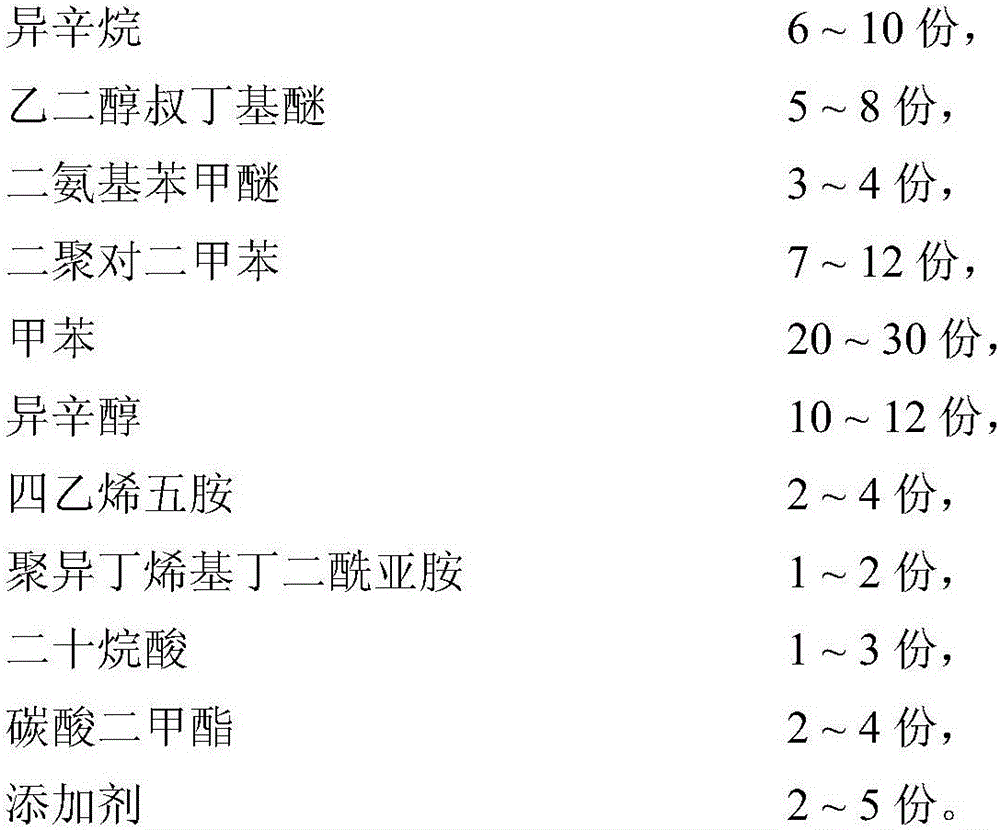

[0038] The gasoline additive in the present embodiment comprises the following components by weight:

[0039]

[0040]

[0041] Wherein, the additive is a mixture of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst, and the mass ratio of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst in the mixture is 1 :3:5:1.

[0042] The preparation process of above-mentioned catalyst is as follows:

[0043](a) Add 1 mass part of cerium ammonium nitrate to 10 mass parts of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution A; 2 mass parts of dibenzoylmethane Add to 10 parts by mass of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution B; add 0.3 parts by mass of sodium hydroxide to 10 parts by mass of deionized water to prepare solution C ;

[0044] (b) At room temperature, add solution B dropwise to solution C to generate a white suspension. After the dropwise addition, co...

Embodiment 3

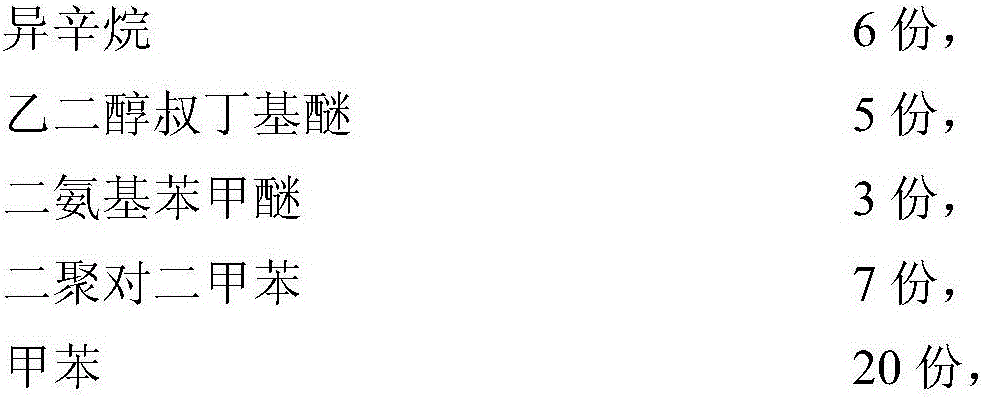

[0051] The gasoline additive in the present embodiment comprises the following components by weight:

[0052]

[0053]

[0054] Wherein, the additive is a mixture of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst, and the mass ratio of phthalic hydrazide, acetylacetone, dimethyl sulfoxide and catalyst in the mixture is 1 :3:6:1.

[0055] The preparation process of above-mentioned catalyst is as follows:

[0056] (a) Add 1 mass part of cerium ammonium nitrate to 10 mass parts of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution A; 2 mass parts of dibenzoylmethane Add to 10 parts by mass of ethanol aqueous solution (V ethanol: V water = 1:1), stir evenly, and prepare solution B; add 0.3 parts by mass of sodium hydroxide to 10 parts by mass of deionized water to prepare solution C ;

[0057] (b) At room temperature, add solution B dropwise to solution C to generate a white suspension. After the dropwise addition, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com