Bacillus amyloliquefaciens for high production of neutral protease

A technology for dissolving starch spores and protease, which is applied in the field of microbial screening, can solve the problems of pollution, unstable fermentation, low fermentation unit of neutral protease, etc., and achieves the effect of increasing yield and having broad prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 The ultraviolet mutagenesis and screening of the bacterium Bacillus amyloliquefaciens FN

[0018] Starting bacteria: Bacillus amyloliquefaciens FN ( Bacillus amylolique faciens FN), the strain was isolated by the inventor Fu Juan in May 2014 from the soil of the forest farm in Laoshan District, Qingdao City, Shandong Province, and can ferment and produce neutral protease.

[0019] Bacterial suspension preparation

[0020] Streak inoculation of the starting bacterium Bacillus amyloliquefaciens FN on LB slant (yeast powder 0.5%, peptone 1%, NaCl 1%, agar 2%), culture at 37°C for 24 hours; add 5 mL of 0.85% sterile saline, Wash all the bacteria on the inclined surface, transfer them into a sterile test tube containing glass beads, vortex and shake for 10 minutes, and completely break into single-cell bacteria; transfer all the bacteria suspension into a 15mL centrifuge tube, and centrifuge at 6000rpm for 3 minutes to collect bacteria cells, take the supernata...

Embodiment 2

[0040] Example 2 Enzymatic property analysis of protease produced by Bacillus amyloliquefaciens FN61

[0041] 2.1 Optimum pH analysis

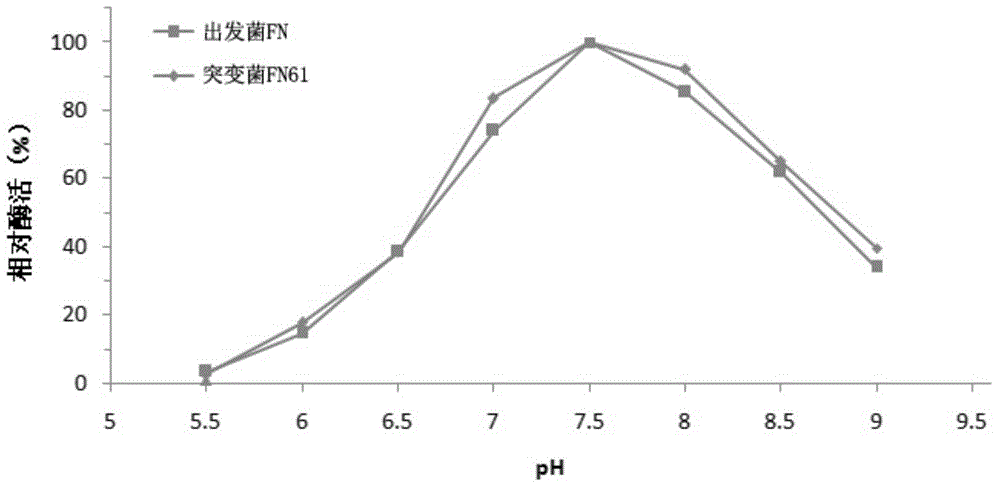

[0042] Using disodium hydrogen phosphate-citric acid buffer solution with pH values of 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, and 9.0, and borax-boric acid buffer solution with pH values of 8.5 and 9.0, the above mutant strain FN61 Dilute with the fermentation supernatant of the starting strain FN, the substrates are also prepared with buffers corresponding to the pH value, and the protease enzyme activity is measured at 40°C, with the highest enzyme activity as 100%, the relative enzyme activity is calculated, and the pH is calculated. - Relative enzyme activity curve. The result is as figure 1 As shown, the optimum pH value of the protease produced by the mutant strain FN61 obtained in the present invention is 7.5, which is a neutral protease, which is consistent with the starting strain. However, the relative enzyme activity of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com