Adhesive for pyrolusite sintering treatment and preparation method thereof

A technology of sintering treatment and adhesive, which is applied in the field of adhesive for pyrolusite sintering treatment and its preparation, to achieve significant economic benefits and environmental protection value, reduce costs, and improve drum strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

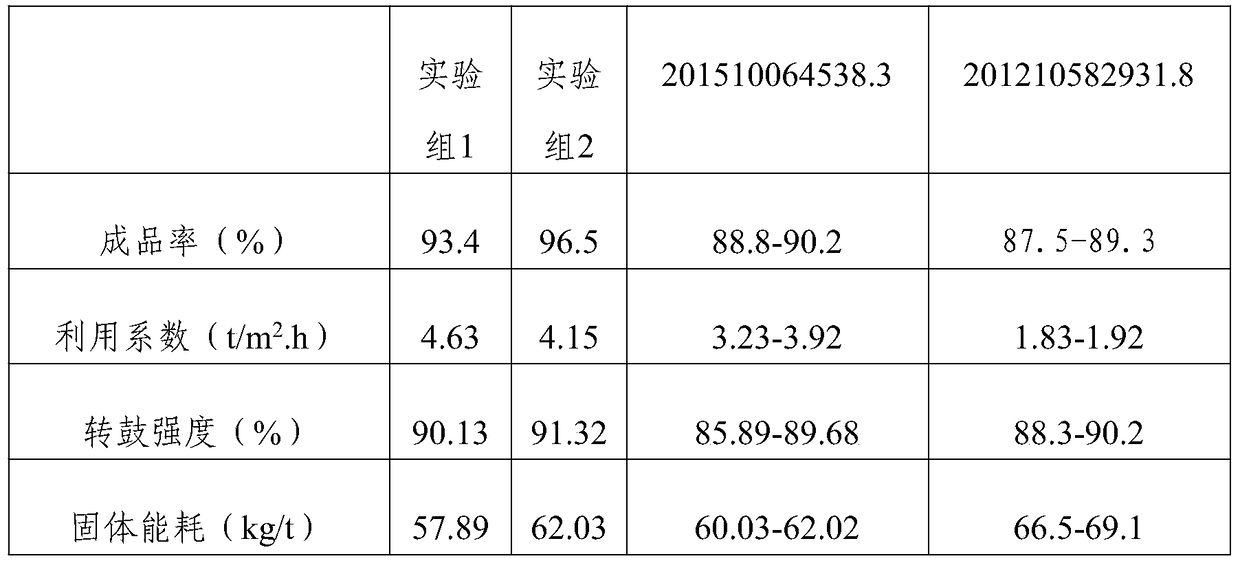

Examples

Embodiment 1

[0022] An adhesive for pyrolusite sintering treatment, the raw material components are 2kg of yellow mud, 10kg of plant ash, 2kg of phosphogypsum, 0.2kg of cement, 3kg of straw powder, 1kg of urea, 1kg of dextrin, 2kg of starch, 2kg of paocyanidin by weight 0.5kg, furfural resin 0.7kg, calcium dihydrogen phosphate 0.01kg, silica powder 0.6kg.

[0023] According to the preparation method, in the process of mixing raw materials, after adding water for stirring treatment, ultrasonic treatment is adopted for 20 minutes, and the frequency of ultrasonic wave is controlled at 100 Hz.

[0024] The silica powder is 180 meshes.

[0025] The straw powder is a mixture of wheat straw powder, corn straw powder and sugarcane straw powder, and the mixing ratio is 5:7:9.

Embodiment 2

[0027] An adhesive for pyrolusite sintering treatment, the raw material components are 7kg of yellow mud, 13kg of plant ash, 7kg of phosphogypsum, 0.5kg of cement, 5kg of straw powder, 3kg of urea, 5kg of dextrin, 3kg of starch, 5kg of stalk powder by weight 1.3kg, furfural resin 1.5kg, calcium dihydrogen phosphate 0.03kg, silicon dioxide powder 1.4kg.

[0028] According to the preparation method, in the process of mixing the raw materials, after adding water to carry out the stirring treatment, ultrasonic treatment is adopted for 30 minutes, and the frequency of the ultrasonic wave is controlled at 700 Hz.

[0029] Specifically include the following steps:

[0030] (1) After mixing yellow mud, plant ash, phosphogypsum, urea, dextrin, starch, furfural resin, and calcium dihydrogen phosphate, add water that accounts for 20% of the weight of the mixture, and adjust its temperature to 100 ° C for 10 s , and then cooled to room temperature for 10s, and then ultrasonically treated...

Embodiment 3

[0035] An adhesive for pyrolusite sintering treatment, the raw material components are 3kg of yellow mud, 11kg of plant ash, 3kg of phosphogypsum, 0.3kg of cement, 3.1kg of straw powder, 1.76kg of urea, 2kg of dextrin, 2.13kg of starch, Paohua alkali 1kg, furfural resin 0.9kg, calcium dihydrogen phosphate 0.015kg, silicon dioxide powder 0.69kg.

[0036] Its preparation method specifically comprises the following steps:

[0037] (1) After mixing yellow mud, plant ash, phosphogypsum, urea, dextrin, starch, furfural resin, and calcium dihydrogen phosphate, add water that accounts for 30% of the weight of the mixture, and adjust its temperature to 130 ° C for 20 s , and then cooled to normal temperature for 60s, and then ultrasonically treated for 30min, the frequency of ultrasonic wave was 700Hz, and then cement, straw powder and Paoflorine were added in sequence, and during the adding process, the temperature was adjusted from normal temperature to the temperature according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com