Production method and equipment of diamond-like carbon powder

A technology of diamond powder and diamond-like film, applied in metal material coating process, gaseous chemical plating, coating and other directions to achieve excellent mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

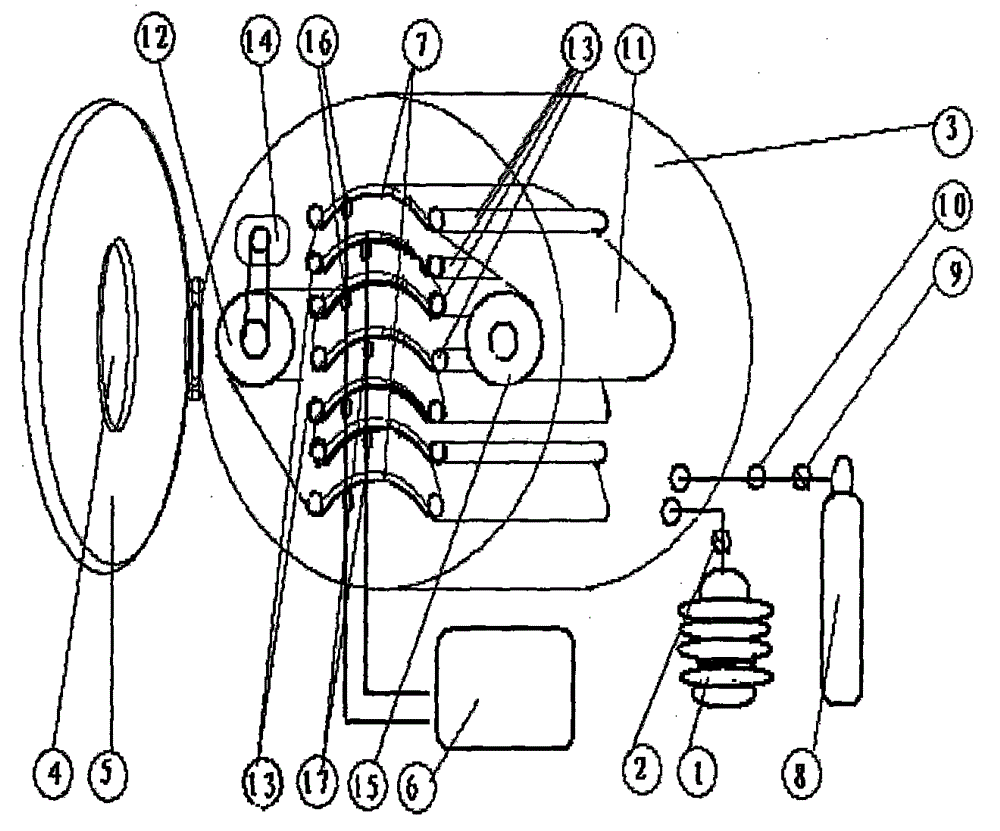

[0010] The preferred scheme of the diamond-like powder production method and equipment includes: a production equipment manufacturing scheme and a production operation flow scheme.

[0011] The vacuum chamber (3) is made of a stainless steel cylinder with a diameter of about 1 meter, a length of about 2 meters and a wall thickness of 5 mm. One end of the cylinder is sealed, and the other end is a sealed door (5) with a sealing ring and a transparent glass viewing window (4) with a diameter of about 100 mm on the edge.

[0012] The interior of the vacuum chamber (3) is equipped with multi-layer arc-surface high-frequency electrodes (7), each layer of arc-surface high-frequency electrodes (7) has a length of about 1.5 meters and a width of about 0.5 meters, and is made of an aluminum plate with a thickness of about 2 mm. Rotatable rollers (13) consistent with the length of the arcuate high-frequency electrodes (7) are installed at both ends of each layer of arcuate high-frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com