Magnesium or magnesium alloy surface treatment method capable of controlling degradation speed

A surface treatment and degradation control technology, which is applied in the field of surface treatment of magnesium or magnesium alloys, can solve the problems of fast hydrogen evolution, affecting clinical treatment effects and human health, and rapid degradation, and achieves low price and excellent biocompatibility , resource-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

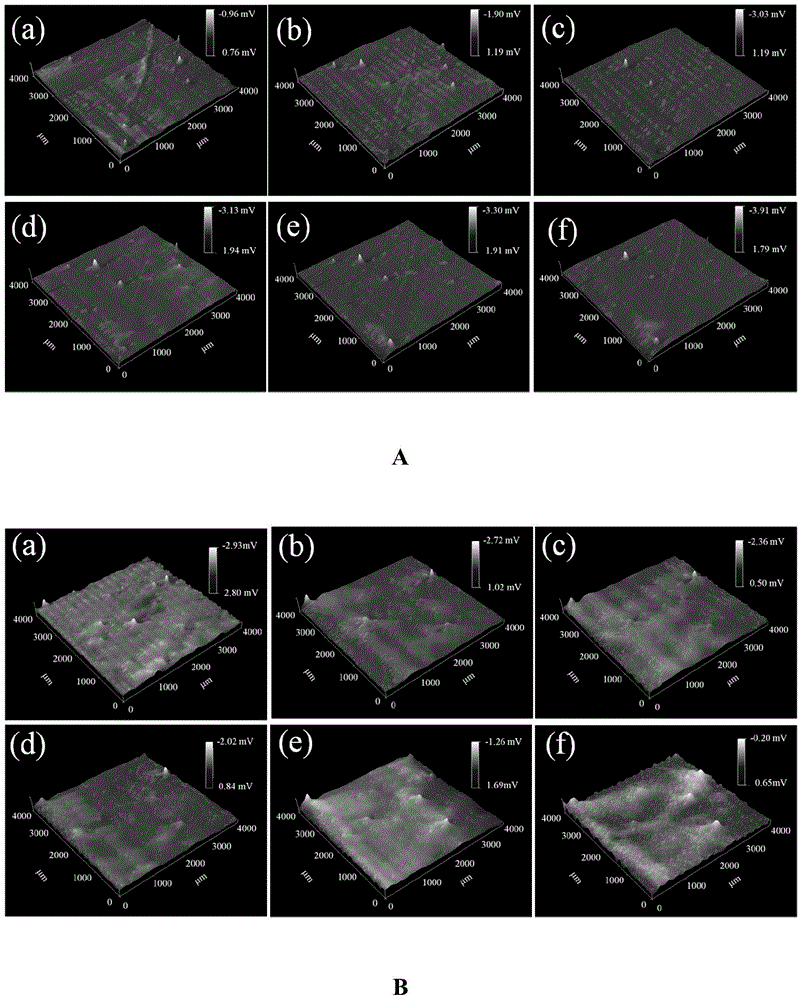

[0032] Coating treatment of embodiment 1 medical magnesium-calcium alloy

[0033] 1. Pretreatment: Use sandpaper to grind the medical magnesium-calcium alloy, and then use 1μm and 0.3μm Al 2 o 3 The polishing powder is used for polishing, and then the polished magnesium-calcium alloy is ultrasonically cleaned in absolute ethanol for 5-10 minutes, and then cleaned with N 2 Blow dry; soak the dry magnesium-calcium alloy in a 20% NaOH solution for passivation for 24h, then clean it with deionized water, N 2 blow dry.

[0034] 2. Preparation of mussel protein solution: before use, dilute mussel protein to 1 mg / mL with 1% citric acid buffer solution, adjust its pH to 4.6 with NaOH solution, and set aside.

[0035] 3. Soak the magnesium-calcium alloy pretreated in step 1 in the mussel protein solution in step 2 for 1 hour, so that the mussel protein can be fully adsorbed on the surface of the magnesium-calcium alloy to form a protein film layer with a thickness of about 3-5 μm ....

Embodiment 2

[0037] Coating treatment of embodiment 2 medical magnesium-calcium alloy

[0038]1. Pretreatment: Use sandpaper to grind the medical magnesium-calcium alloy, and then use 1μm and 0.3μm Al 2 o 3 The polishing powder is used for polishing, and then the polished magnesium-calcium alloy is ultrasonically cleaned in absolute ethanol for 5-10 minutes, and then cleaned with N 2 Blow dry; soak the dry magnesium-calcium alloy in a 20% NaOH solution for passivation for 24h, then clean it with deionized water, N 2 blow dry.

[0039] 2. Preparation of mussel protein solution and nano-cerium oxide solution: before use, dilute mussel protein to 1 mg / mL with 1% citric acid buffer solution, adjust its pH to 4.6 with NaOH solution, and set aside; A nano-cerium oxide solution with a concentration of 500ppm was prepared in deionized water.

[0040] 3. Place the magnesium-calcium alloy pretreated in step 1 in the mussel protein solution of step 2 and soak for 1 hour, and then soak it in the n...

Embodiment 3

[0043] In step 3, the magnesium-calcium alloy is placed in the mussel protein solution and soaked for 1 hour to apply a layer of protein film, then dry it naturally for 2 hours, and then apply the second layer of protein film according to the same operation, and the other steps are the same as in Example 1. Form a double protein film layer on the surface of the magnesium-calcium alloy.

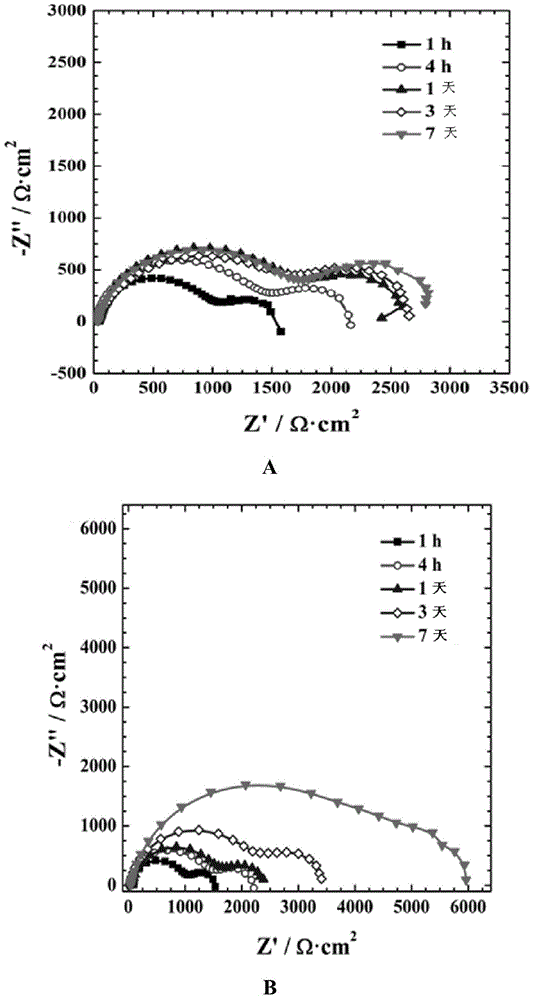

[0044] After the above coating treatment, the electrochemical impedance spectroscopy test shows that the corrosion degradation rate of the magnesium-calcium alloy is reduced by about 1 / 4 of that before the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com