Electrochromic device based intelligent electronic curtain and production method thereof

The technology of an electrochromic device and a manufacturing method is applied in the field of machinery, and can solve the problems such as the inability to adjust the sunlight transmittance at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

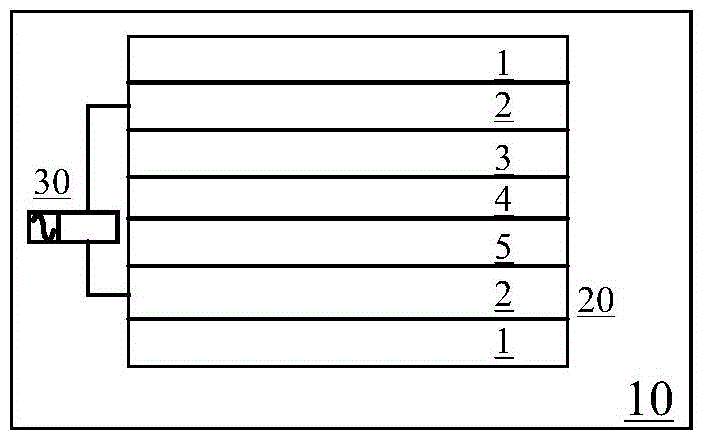

[0067] The curtain part 10, the electrochromic device 20 and the controller 30 are assembled.

[0068] Making the electrochromic device 20 includes:

[0069] (1) WO 3 Nano film 5 material electrochromic electrode preparation:

[0070] a. Magnetron sputtering a fluorine-doped tin oxide (FTO) film 2 on the surface of a tempered glass 1 of a specific size, with a thickness of about 320 nm;

[0071] b. Perform high temperature annealing treatment to obtain FTO conductive glass with high strength, then ultrasonically clean the FTO conductive glass in the order of ultrapure water, acetone, and ethanol for 15 minutes, and dry it for later use; then, use the magnetron sputtering method Coating W film on FTO glass, its thickness is 220nm; W film is used as WO 3 Growth source of nanowires;

[0072] c. Prepare a 0.2 mol / L sodium tungstate aqueous solution, then dropwise add 3 mol / L hydrochloric acid until no more precipitation occurs, and after centrifugal washing, the obtained preci...

Embodiment 2

[0087] The curtain part 10, the electrochromic device 20 and the controller 30 are assembled.

[0088] Making the electrochromic device 20 includes:

[0089] (1) WO 3 Nano film 5 material electrochromic electrode preparation:

[0090] a. Magnetron sputtering a fluorine-doped tin oxide (FTO) film 2 on the surface of a tempered glass 1 of a specific size, with a thickness of about 360 nm;

[0091] b. Perform high temperature annealing treatment to obtain FTO conductive glass with high strength, then ultrasonically clean the FTO conductive glass in the order of ultrapure water, acetone, and ethanol for 15 minutes, and dry it for later use; then, use the magnetron sputtering method Coating W film on FTO glass, its thickness is 200nm; W film is used as WO 3 Growth source of nanowires;

[0092] c. Prepare a 0.2mol / L sodium tungstate aqueous solution, then add 3mol / L hydrochloric acid dropwise until no precipitation occurs, and then dissolve the obtained precipitate in hydrogen per...

Embodiment 3

[0107] The curtain part 10, the electrochromic device 20 and the controller 30 are assembled.

[0108] Making the electrochromic device 20 includes:

[0109] (1) WO 3 Nano film 5 material electrochromic electrode preparation:

[0110] a. Magnetron sputtering a fluorine-doped tin oxide (FTO) film on the surface of tempered glass 1 with a specific size, with a thickness of about 340nm;

[0111] b. Perform high-temperature annealing treatment on it to obtain FTO conductive glass with higher strength, then ultrasonically clean the FTO conductive glass for 15 minutes in the order of ultrapure water, acetone, and ethanol, and dry it for later use; then, use magnetron sputtering method Coating W film on FTO glass with a thickness of 210nm; W film is used as WO 3 a growth source for the nanowires;

[0112] c. Prepare a 0.2mol / L sodium tungstate aqueous solution, then add 3mol / L hydrochloric acid dropwise until no precipitation occurs, and then dissolve the obtained precipitate in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com