Itopride hydrochloride combination

A technology of itopride hydrochloride and tablet core, applied in the field of itopride hydrochloride controlled-release tablet composition, can solve the problems that the release rate cannot reach 70%, cannot meet the clinical requirements of controlled-release preparations, etc., and achieve the utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

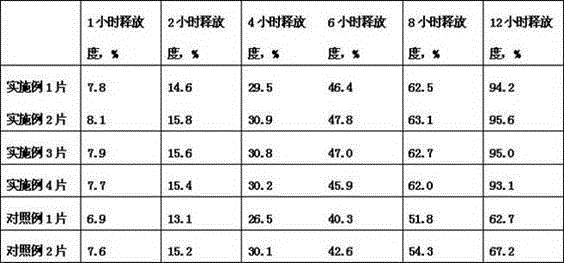

Examples

Embodiment 1

[0030] Embodiment 1, itopride hydrochloride 75g, polyethylene glycol 100060g, lactose 50g, mannitol 20g, micropowder silica gel 5g, povidone K308g. According to the preparation method described in the technical solution part of the present invention, 1000 tablet cores are prepared.

[0031] Coating layer: The mass ratio of ethyl cellulose to hypromellose is 35:10, dissolved in 90% ethanol, the weight of the coating is increased by 11%, dried, and laser-drilled with a pore size of 0.5 mm.

Embodiment 2

[0032] Embodiment 2, itopride hydrochloride 150g, polyethylene glycol 100090g, lactose 80g, mannitol 40g, micropowder silica gel 9g, povidone K3010g. According to the preparation method described in the technical solution part of the present invention, 1000 tablet cores are prepared.

[0033] The mass ratio of ethyl cellulose to hypromellose is 35:10, dissolved in 90% ethanol, and the weight of the coating is increased by 10%. Drying, laser drilling, hole diameter 0.5mm.

Embodiment 3

[0034] Example 3, 100 g of itopride hydrochloride, 100075 g of polyethylene glycol, 70 g of lactose, 30 g of mannitol, 7 g of micronized silica gel, and 309 g of povidone K. According to the preparation method described in the technical solution part of the present invention, 1000 tablet cores are prepared.

[0035] The mass ratio of ethyl cellulose to hypromellose is 35:10, dissolved in 90% ethanol, and the weight gain of the coating is 10.5%. Drying, laser drilling, hole diameter 0.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com