A method and device for treating organic waste gas

A technology of organic waste gas and waste gas, applied in separation methods, chemical instruments and methods, waste fuels, etc., can solve problems such as secondary pollution, and achieve the effects of increasing mechanical strength, high packing strength, and thinning thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

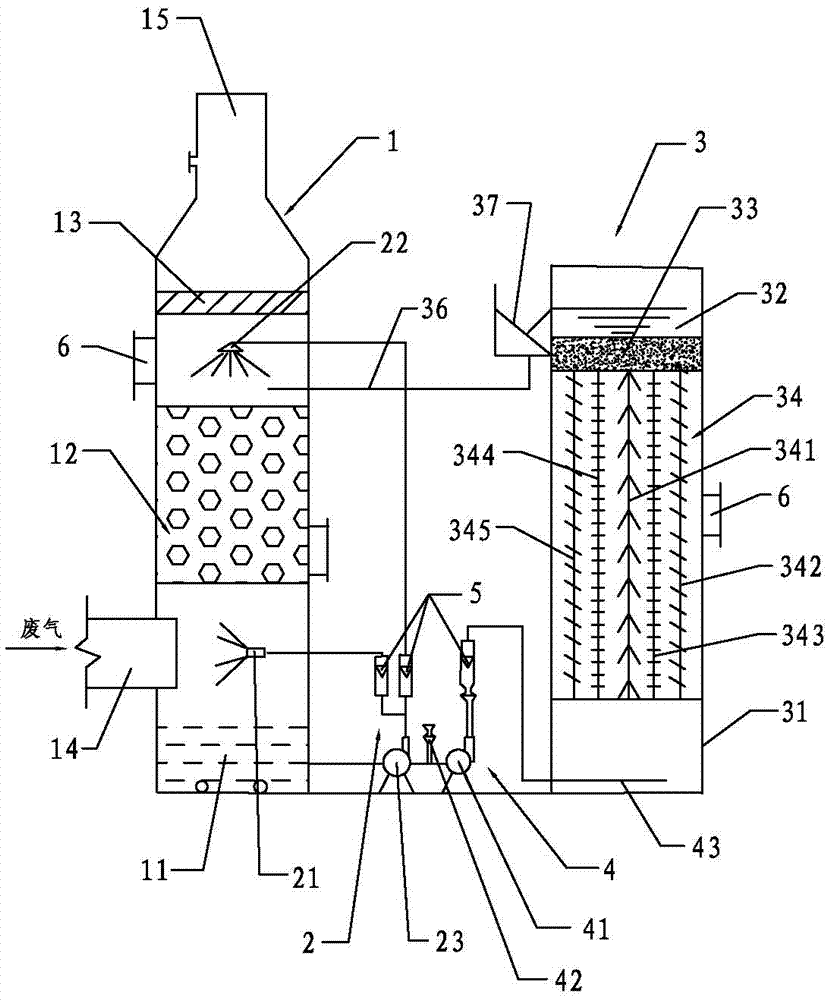

[0050] A method for treating organic waste gas, comprising the steps of:

[0051] Step a: Pass the organic waste gas into the packing absorption tower 1, use the spray head to spray the spray liquid on the organic waste gas, and the spray liquid absorbs the organic pollutants in the organic waste gas;

[0052] Step b: The organic waste gas sprayed in step a passes upwards through the packing layer 12 of the low-resistance packing, and is secondarily absorbed by the spray liquid sprayed downwards to obtain a gas-liquid mixture; the packing layer 12 of the step b is Multi-faceted hollow ball packing.

[0053] And the spray liquid at the bottom of the packed absorption tower is catalyzed and oxidized by the catalytic biochemical reactor 3, and the overflow liquid formed by microbial decomposition passes through the packing layer 12 and falls back to the bottom of the packed absorption tower 1. The catalytic biochemical reactor 3 is provided with biological Filler to decompose or...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is that: the packing layer 12 in step b of this embodiment is a stepped ring packing. The suspended biological filler 34 includes a strip-shaped far-infrared biological filler 341 and a soft filler 344 . The transition metal oxide is cobalt metal oxide, and the natural mineral material is expanded vermiculite.

[0076] The spray width of the first shower head 21 is 60°, the position of the first shower head 21 does not exceed the central axis of the packed absorption tower 1, the spray width of the second shower head 22 is 90°, and the second spray head 22 has a spray width of 90°. The spray range of the head 22 covers the surface of the packing layer 12, and the spray liquid-gas ratio of the first shower head 21 and the second shower head 22 is 5 L / m 3 .

[0077] The rest of the content of this embodiment is the same as that of Embodiment 1 and will be repeated here.

Embodiment 3

[0079] The difference between this embodiment and Embodiment 1 is that: the packing layer 12 in step b of this embodiment is a Pall ring packing. The suspended biological filler 34 includes a strip-shaped far-infrared biological filler 341 and a semi-soft filler 343 . The transition metal oxide is molybdenum metal oxide, and the natural mineral material is a mixture of bentonite and diatomite at a mass ratio of 1:1.

[0080] The catalytic biochemical reactor 3 is fed with cultured and domesticated dominant microorganisms, and the microorganisms oxidize and degrade the organic matter absorbed by spraying.

[0081] The spray width of the first spray head 21 is 80°, the position of the first spray head 21 is no more than the central axis of the packed absorption tower 1, the spray width of the second spray head 22 is 100°, and the second spray head 22 has a spray width of 100°. The spray range of the head 22 covers the surface of the packing layer 12, and the spray liquid-gas ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com