Kieselguhr/coal ash particle adsorbent and preparing method and application of kieselguhr/coal ash particle adsorbent

A particle adsorbent, fly ash technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of difficult solid-liquid separation, clogging of equipment, low cost, etc., to reduce the follow-up treatment. cost, solve the effect of stacking and occupying space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of diatomite / fly ash granular adsorbent

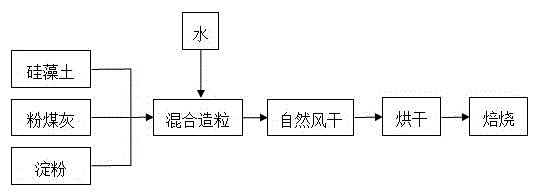

[0044] 1. Preparation method

[0045] S1. Sift diatomaceous earth and fly ash through 200 meshes, according to parts by weight. Diatomaceous earth: fly ash: starch: water = 3:2:1:2 and mix evenly, add water and stir to make a mud mass, and let stand Aging for 24h;

[0046] S2. Granulate the sludge obtained in S1 to form green balls with a particle size of 2 to 3 mm, and dry them naturally at room temperature for 24 hours;

[0047] S3. Dry the particles obtained from S2 at 105°C for 6 hours;

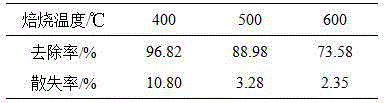

[0048] S4. Place the particles obtained in S3 in a muffle furnace, roast them at 500° C. for 1 hour, perform roasting and shaping, and then cool them naturally to obtain a diatomaceous earth / fly ash particle adsorbent.

[0049] 2. After measurement, the specific surface area of the diatomite / fly ash particle adsorbent prepared above is 27.093m 2 / g, the water absorption rate is 31.90%.

Embodiment 2

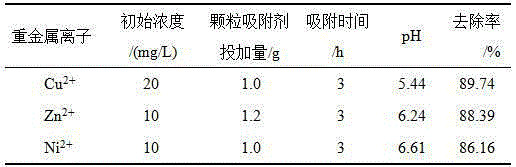

[0050] Example 2 Simulation application test

[0051] 1. Weigh a certain amount of diatomaceous earth / fly ash particle adsorbent into a 250mL Erlenmeyer flask, add Cu 2+ 20mg / L, Zn 2+ 10mg / L or Ni 2+ 50mL of 10mg / L heavy metal ion solution, control the initial pH of the solution to 5.44~6.61, and vibrate and adsorb at room temperature for 3h.

[0052] 2. See Table 1 for the removal rate of adsorbed heavy metal ions.

[0053] Table 1 Removal rate of heavy metal ions by diatomite / fly ash particulate adsorbent

[0054]

Embodiment 3

[0055] Example 3 Wastewater treatment application

[0056] 1. Take the electroplating wastewater after physical and chemical precipitation for experiments. The pH of the wastewater is determined to be 9.23 and the total copper concentration is 2.104mg / L.

[0057] 2. Weigh 0.6g of diatomaceous earth / fly ash particulate adsorbent, place it in a 250mL Erlenmeyer flask, add 50mL of electroplating wastewater that has been adjusted to pH=7, and vibrate for 2.5-3h at room temperature.

[0058] 3. The total copper concentration in the wastewater after treatment is 0.28mg / L, and the removal rate reaches 86.69%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com