Double perovskite type metal oxide catalyst and preparation method thereof

A double perovskite and catalyst technology, applied in the field of double perovskite metal oxide catalyst and its preparation, can solve the problems of low catalytic activity and poor high temperature stability, and achieve high catalytic activity, increased specific surface area, high The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

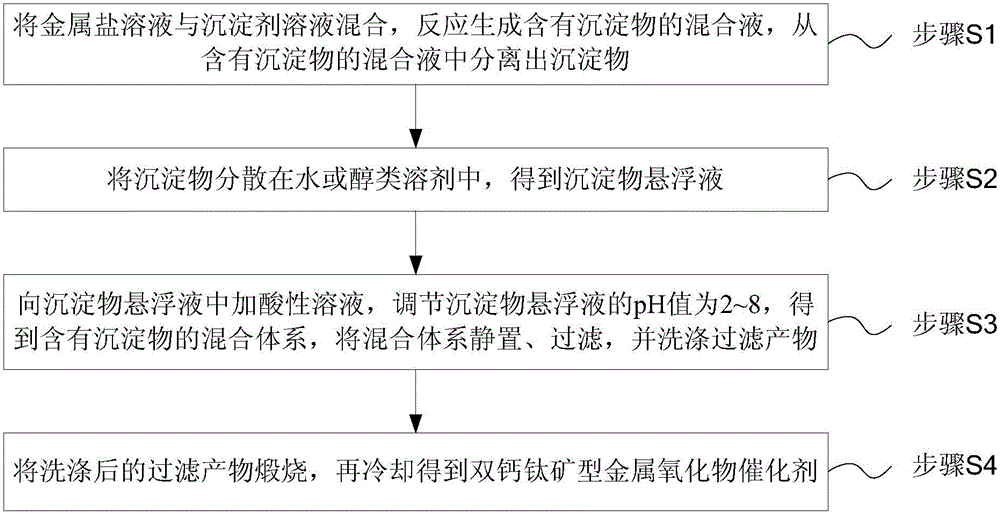

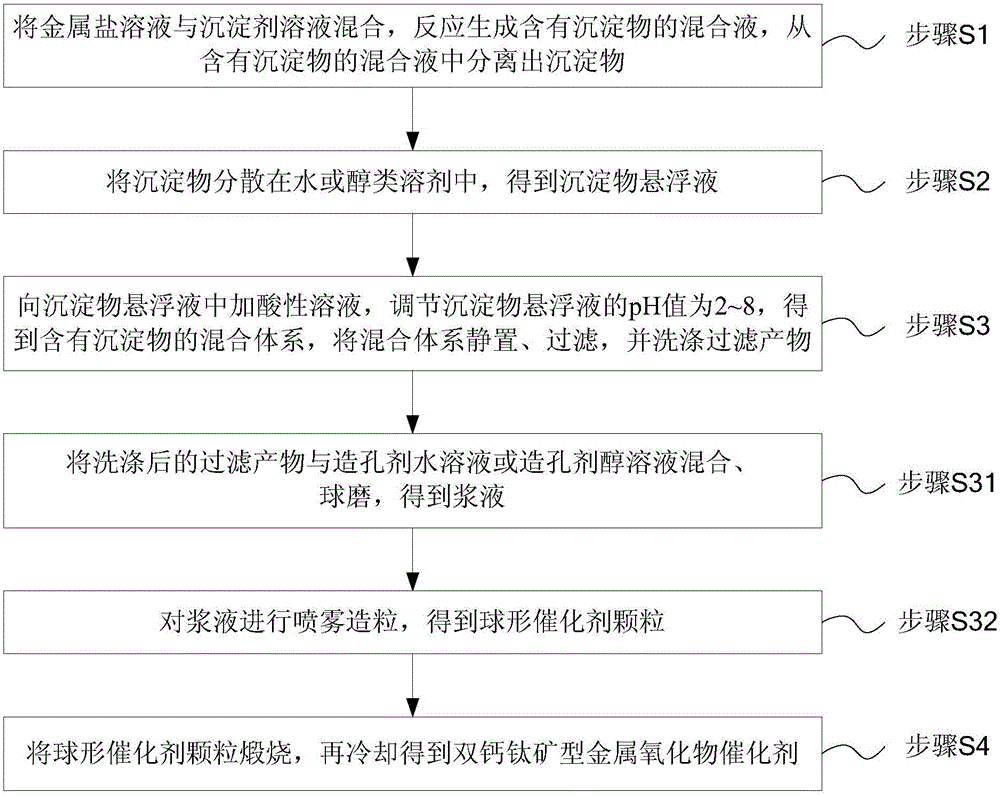

[0020] The embodiment of the present invention also provides a method for preparing a double perovskite type metal oxide catalyst, such as figure 1 Shown, including:

[0021] Step S1: Mix the metal salt solution with the precipitant solution, react to generate a mixed liquid containing precipitates, and separate the precipitates from the mixed liquid containing precipitates; wherein the metal salt solution can be a nitrate solution or an acetate solution , Hydrochloride solution or sulfate solution, the precipitant solution can be a precipitant solution containing hydroxide ions or carbonate ions, such as ammonia solution or sodium hydroxide solution; the metal salt solution and The reaction conditions for mixing the precipitant solution can be: the reaction temperature is 0-40°C, such as 20°C or 30°C; the concentration of the metal salt solution is 1-5 mol / L, such as 3mol / L or 4mol / L; The concentration is 0.1 to 5 mol / L, preferably 1 to 5 mol / L, for example, 3 mol / L or 4 mol / L. ...

Embodiment 1

[0034] Step S1. A nitrate aqueous solution or acetate solution with a concentration of 1 to 5 mol / L is configured as a metal salt aqueous solution, an ammonia solution with a concentration of 1 to 5 mol / L is configured as a precipitating agent aqueous solution, and the metal salt aqueous solution and the precipitating agent aqueous solution, etc. The volume is mixed quickly so that the reaction can proceed quickly and produce a precipitate. In this way, more crystal nuclei can be quickly generated, the particle size of the catalyst can be reduced, and a catalyst material with a high specific surface area can be obtained. At the same time, the reaction process is controlled to be carried out in an environment of 0-40°C, and a lower temperature can inhibit the growth rate of crystal nuclei and promote the generation rate of crystal nuclei.

[0035] Step S2, uniformly disperse the precipitate generated in the above step S1 in water or alcohol solvent to obtain a precipitate suspensi...

Embodiment 2

[0041] Step S1. The nitrate aqueous solution or acetate aqueous solution with a concentration of 1 to 5 mol / L is configured as the metal salt aqueous solution, and the sodium hydroxide solution with a concentration of 1 to 5 mol / L is configured as the precipitation agent aqueous solution, and the metal salt aqueous solution is added dropwise to In the aqueous precipitant solution, a precipitate is formed. In this way, metal ions can be precipitated instantaneously at the same time, generating more crystal nuclei, reducing the particle size of the catalyst, and obtaining a catalyst material with a high specific surface area. At the same time, the reaction process is controlled to be carried out in an environment of 0-40°C, and a lower temperature can inhibit the growth rate of crystal nuclei and promote the generation rate of crystal nuclei.

[0042] Step S2, uniformly disperse the precipitate generated in the above step S1 in water or alcohol solvent to obtain a precipitate suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com