Laser-MAG welding method for steel plate of medium thickness and superhigh strength

A welding method and ultra-high-strength technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to reduce costs, reduce the time to replace MAG welding guns, and increase the flow of shielding gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

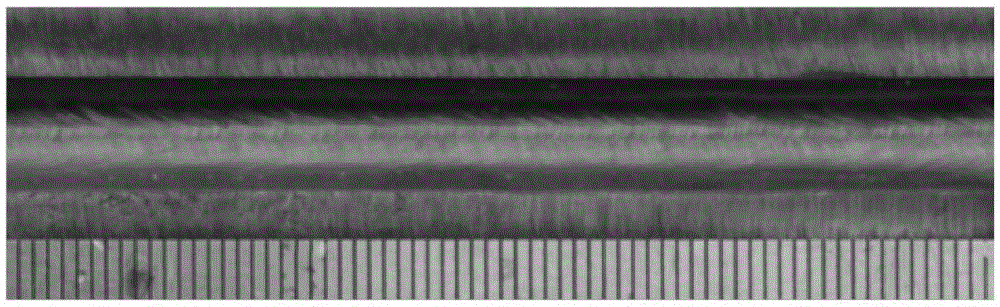

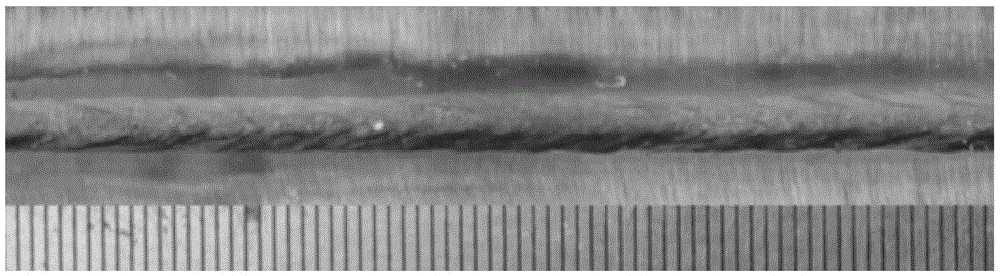

Examples

specific Embodiment approach 1

[0032] Specific embodiment 1: A kind of laser-MAG welding method of medium-thick ultra-high-strength steel plate of this embodiment, others are carried out according to the following steps:

[0033] 1. Before welding, the parts to be welded are processed into double V-shaped grooves, double U-shaped grooves, double Y-shaped grooves or double U-shaped grooves with blunt edges, and the processed double-sided grooves Grinding or cleaning the surface of the mouth and both sides, and fixing the polished or cleaned workpiece to be welded on the welding fixture;

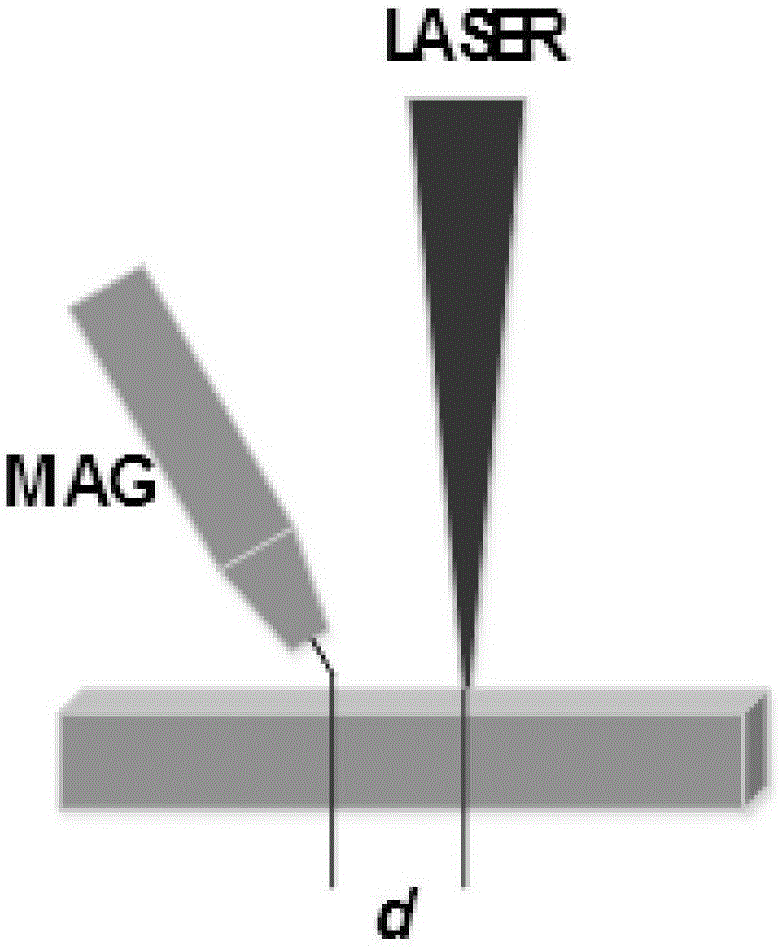

[0034] 2. Rigidly fix the laser head and MAG welding torch;

[0035] 3. Set welding process parameters:

[0036] Bottom welding: the defocus amount is ﹣3~﹢3mm, the laser power is 3000~5000W, the arc current is 100~200A, the laser arc distance is 5~6mm, the welding speed is 50~500mm / min, and the shielding gas is Ar gas , the protective gas flow rate is 30-40L / min;

[0037] Filler welding: the defocus amount is ﹣3~﹢3mm, th...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the laser is CO 2 Gas laser, YAG solid-state laser or semiconductor laser. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment is different from Embodiment 1 in that: MAG adopts FroniusTPS4000 MAG arc welding machine and fiber laser-MAG composite welding head. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com