Preparation method of photocatalytic foam ceramics

A foamed ceramic and photocatalytic technology, which is applied in the field of photocatalytic foamed ceramics preparation, can solve the problems of high energy consumption, limited load of foamed ceramics, inability to greatly improve photocatalytic efficiency, etc., and achieves increased contact area, Improve photocatalytic performance, the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

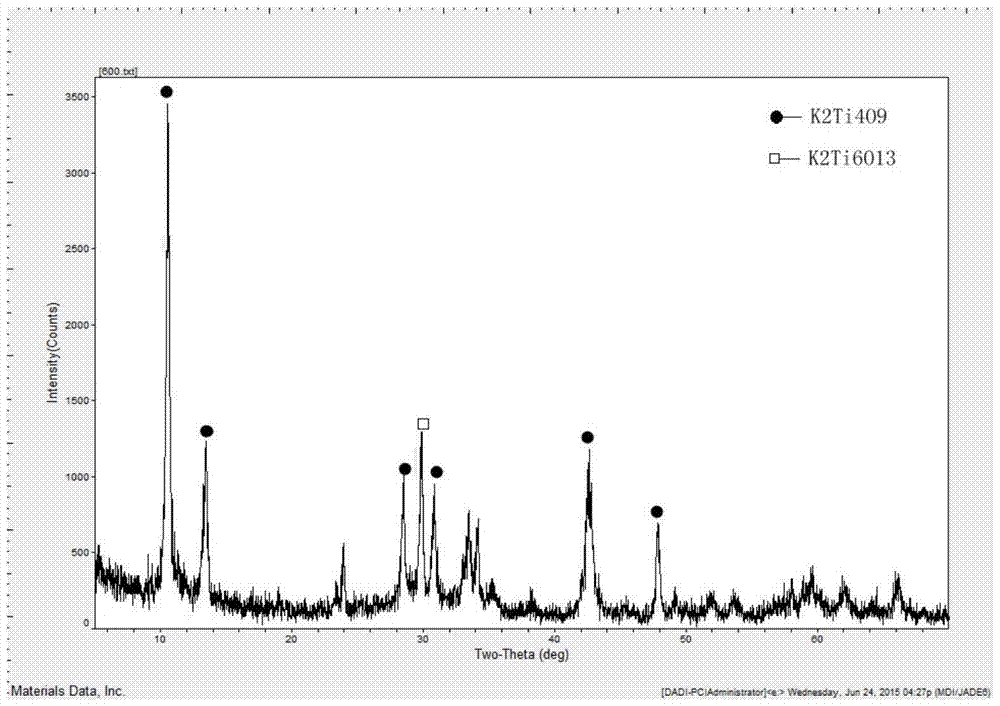

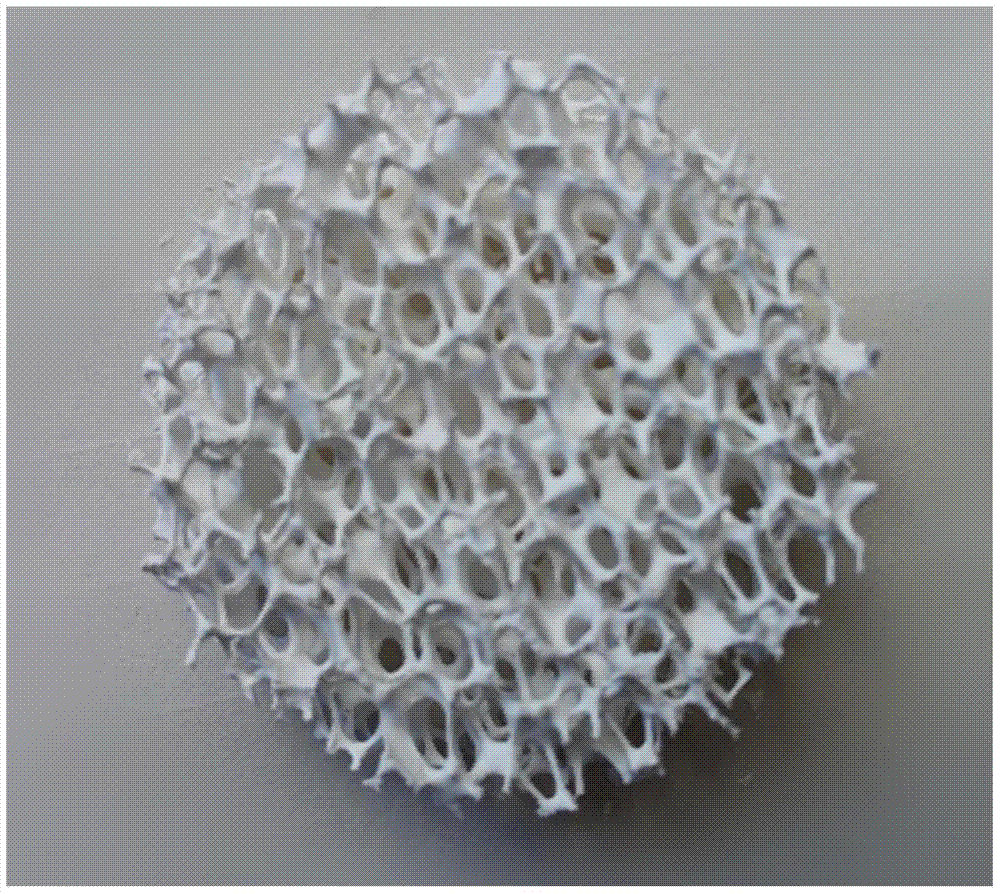

Embodiment 1

[0034] Put the polyurethane foam in 10wt% NaOH solution, treat it at 60°C for 4 hours, rub and wash it repeatedly, then soak the foam in a certain concentration of CMC for 24 hours, and dry it for later use; take 150g of potassium tetratitanate raw powder and place it in a 2L ball mill In the tank, according to the mass ratio of the ball to the material is 2:1, put the balls and the original powder of potassium tetratitanate in the ball mill tank for ball milling for 10 hours, take out the milled potassium tetratitanate powder, wash it repeatedly with deionized water, and vacuum filter , dry; take 100 g of potassium tetratitanate whiskers after washing and drying, add deionized water to disperse them, add stearic acid relative to the mass of potassium tetratitanate whiskers in an amount of 1% to the suspension, and place it in a heat-collecting constant temperature Stir in a heating stirrer at 80°C for 20min, filter with suction, and dry; 30g of the obtained modified potassium ...

Embodiment 2

[0037]Put the polyurethane foam in 20wt% NaOH solution, treat it at 60°C for 2 hours, rub and wash it repeatedly, then soak the foam in a certain concentration of PVA for 24 hours, and dry it for later use; take 150g of potassium tetratitanate raw powder and place it in a 2L ball mill In the tank, according to the mass ratio of the ball to the material is 2:1, put the balls and the original powder of potassium tetratitanate in the ball mill tank for ball milling for 5 hours, take out the milled potassium tetratitanate powder, wash it repeatedly with deionized water, and vacuum filter , and dry; take 100 g of potassium tetratitanate whiskers washed and dried, add deionized water to disperse them, add stearic acid relative to the mass of potassium tetratitanate whiskers at 10% to the suspension, and place in a heat-collecting constant temperature Stir in a heating mixer at 100°C for 5 minutes, suction filter, and dry; take 23.75 g of modified potassium tetratitanate whiskers, 1.2...

Embodiment 3

[0040] Put the polyurethane foam in 15wt% NaOH solution, treat it at 60°C for 3 hours, rub and wash it repeatedly, then soak the foam in a certain concentration of PVA for 24 hours, and dry it for later use; take 150g of potassium tetratitanate raw powder and place it in a 2L ball mill In the tank, according to the mass ratio of the ball to the material is 2:1, put the balls and the original powder of potassium tetratitanate in the ball mill tank for ball milling for 6 hours, take out the milled potassium tetratitanate powder, wash it repeatedly with deionized water, and vacuum filter , and dry; take 100 g of potassium tetratitanate whiskers washed and dried, add deionized water to disperse them, add stearic acid relative to the mass of potassium tetratitanate whiskers at 2% to the suspension, and place in a heat-collecting constant temperature Stir in a heating mixer at 85°C for 15 minutes, filter with suction, and dry; take 31.5g of modified potassium tetratitanate whiskers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com