New technology for separating isopropanol-isopropyl ether azeotrope by using ionic liquids

A technology of azeotropic mixtures and ionic liquids, applied in the preparation of organic compounds, separation/purification of ethers, preparation of hydroxyl compounds, etc., can solve the problems of large amount of extractant, low yield, difficult to handle, etc., and achieve high yield , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

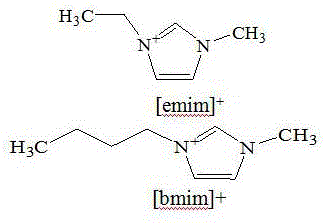

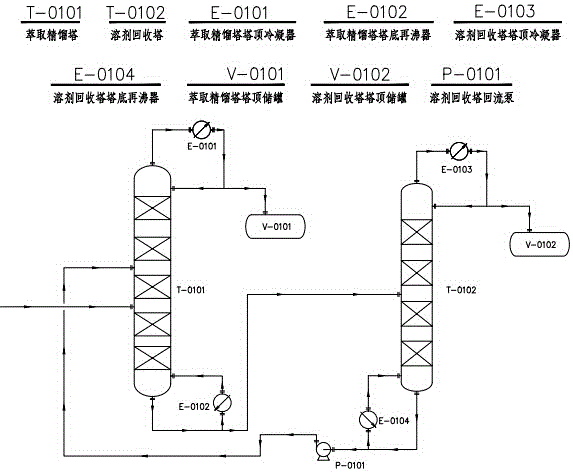

[0012] Embodiment 1: adopt continuous rectification device, drop into the heating kettle of extractive distillation column isopropanol-isopropyl ether 500L (wherein isopropanol is 0.22%, isopropyl ether is 78%, all are mole percentage), the extraction agent selected for the test was ionic liquid [emim] + [BF 4 ] - , continuously add raw materials and extractant to the extractive distillation tower, the feed rate is 100L / h, 40L / h respectively, open the heat source of the extractive distillation tower and the condensed water of the condenser, wait for the temperature at the top of the extractive distillation tower to be stable After reflux for a period of time, add extractant [emim] to the upper part of the extractive distillation column + [BF 4 ] - , the ratio of extractant to feed is 2:5, when the temperature of the extractive distillation tower is 68.5°C, the isopropyl ether product will be extracted continuously at the top of the extractive distillation tower, and the re...

Embodiment 2

[0013] Embodiment 2: experimental apparatus and operation method are the same as embodiment 1, and extractant adopts [bmim] + [BF 4 ] - .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com