Chloramphenicol molecularly imprinted polymer and preparation method thereof

A technology of molecular imprinting and polymers, applied in alkali metal compounds, chemical instruments and methods, and other chemical processes, to achieve the effects of easy control of reaction conditions, simple operation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

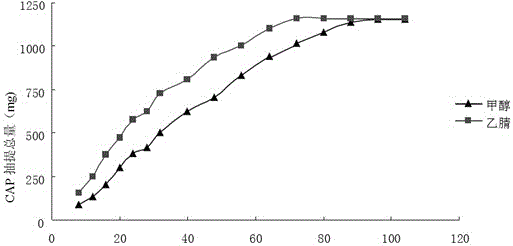

[0030] Example 1 Research on the Removal Method of Chloramphenicol in Chloramphenicol Molecularly Imprinted Polymer

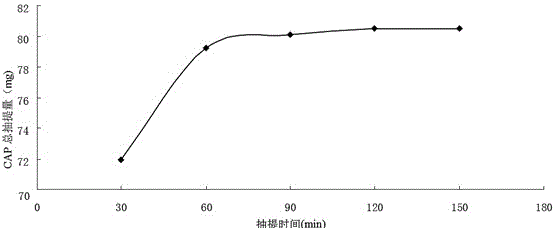

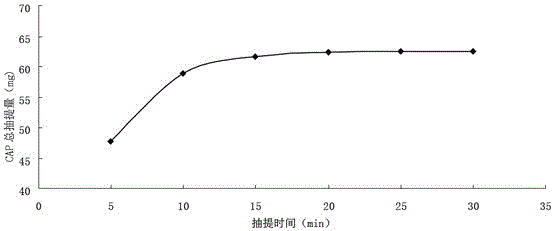

[0031] 1) Soxhlet extraction method

[0032] With methacrylic acid (MAA) as a functional monomer, EDMA as a crosslinking agent, AIBN as an initiator, the MIPs prepared by thermal polymerization with a CAP content of 1.296g are put into the extraction chamber of a Soxhlet extractor, Add 150mL of methanol and adjust the temperature of the constant temperature water bath so that the methanol in the extraction chamber is evacuated every 45min, and 50uL of the extract is taken every 4 hours to measure the content of CAP and calculate the total extraction of CAP.

[0033] In addition, the same weight of MIPs prepared by the same method was put into another Soxhlet extractor, and acetonitrile was used as the extracting liquid, and the content of CAP was determined and the total extraction amount of CAP was calculated in the same way.

[0034] Table 1 The relation...

Embodiment 2

[0048] Embodiment 2 methacrylic acid is the optimization of the preparation condition of functional monomer

[0049] 1) Influence of porogen

[0050] The porogen determines the degree of bonding between the template molecule and the functional monomer, and also affects the hole structure of the molecularly imprinted polymer, thereby affecting its matching with the target molecule in terms of spatial structure. In order to investigate the influence of the porogen, Dissolve 161.55mg CAP in 2.5mL of methanol, acetonitrile, acetone and tetrahydrofuran, add 0.17mL of MAA as a functional monomer, add 1.888mL of DMA and 23.16mg of AIBN after fully reacting, mix well and transfer to an ampoule, ultrasonication, nitrogen deoxygenation , sealed, and placed in a constant temperature water bath at 60°C for 24 hours to react to obtain a polymer. After fully extracting CAP, the binding ability of the polymers to CAP was determined respectively (B). The results are shown in Table 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com