Preparation method of spiral cylindrical polypyrrole

A polypyrrole and columnar technology, applied in the field of polypyrrole preparation, can solve the problems of increasing the complexity of the synthesis process, unfavorable performance improvement and popularization and application of polypyrrole products, mechanical or chemical damage, etc., so as to avoid mechanical or chemical damage, manufacture Low cost and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

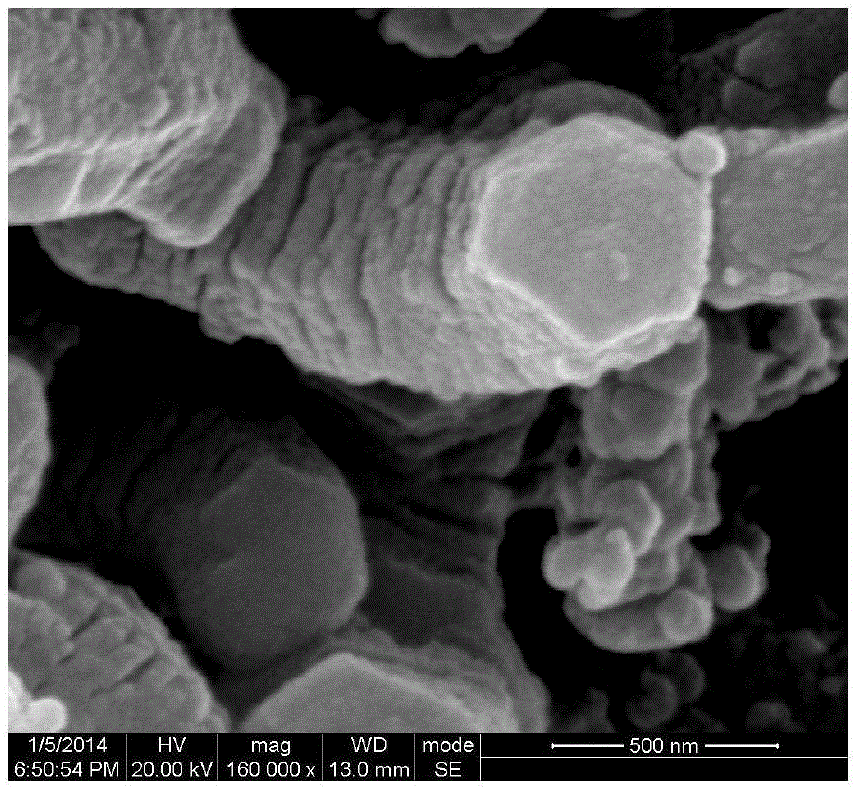

Embodiment 1

[0026] A kind of preparation method of helical columnar polypyrrole, its concrete practice is:

[0027] A, preparation of hydrosol: add sodium indigo disulfonate into distilled water, stir to fully dissolve sodium indigo disulfonate, obtain sodium indigo disulfonate hydrosol, and the molar concentration of sodium indigo disulfonate in the hydrosol is 0.0050 mol / L;

[0028] B. Preparation of the reaction mixture: take 180ml of the hydrosol obtained in step a, then add 1.38ml of pyrrole, and then magnetically stir for 15min in an ice bath until the temperature of the mixture drops to 0°C to obtain the reaction mixture;

[0029] C, the preparation of initiator solution: FeCl 3 ·6H 2 O was added to distilled water and stirred well until the FeCl 3 ·6H 2 O is completely dissolved, and the initiator solution is obtained, in which FeCl 3 The molar concentration is 0.05mol / L;

[0030] D. Pyrrole polymerization reaction: 20 ml of the initiator solution prepared in step c was adde...

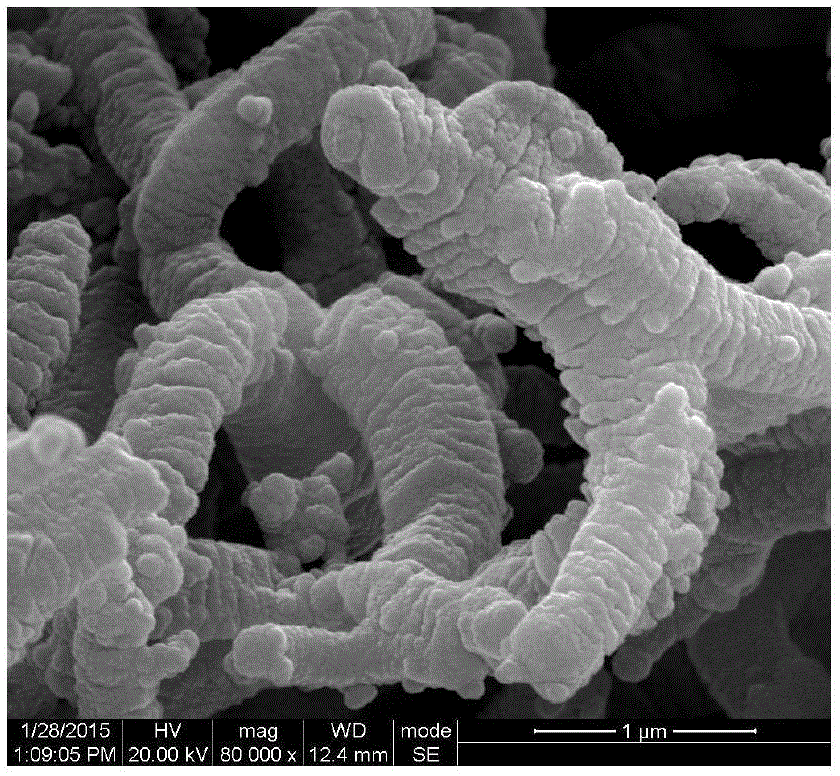

Embodiment 2

[0033] A kind of preparation method of helical columnar polypyrrole, its concrete practice is:

[0034] A, preparation of hydrosol: add sodium indigo disulfonate into distilled water, stir to fully dissolve sodium indigo disulfonate, obtain sodium indigo disulfonate hydrosol, and the molar concentration of sodium indigo disulfonate in the hydrosol is 0.0025 mol / L;

[0035] B. Preparation of the reaction mixture: take 180ml of the hydrosol obtained in step a, then add 1.38ml of pyrrole, and then magnetically stir for 25min in an ice bath until the temperature of the mixture drops to 5°C to obtain the reaction mixture;

[0036] C, the preparation of initiator solution: FeCl 3 ·6H 2 O was added to distilled water and stirred well until the FeCl 3 ·6H 2 O is completely dissolved, and the initiator solution is obtained, in which FeCl 3 The molar concentration is 0.05mol / L;

[0037] D. Polymerization of pyrrole: 20 ml of the initiator solution prepared in step c was added drop...

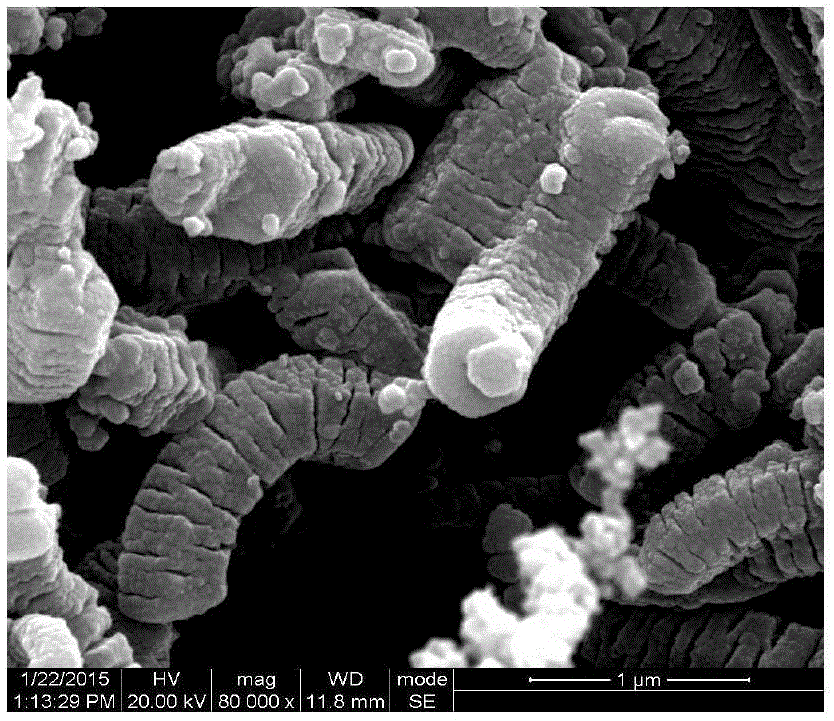

Embodiment 3

[0040] A kind of preparation method of helical columnar polypyrrole, its concrete practice is:

[0041] A, preparation of hydrosol: add sodium indigo disulfonate into distilled water, stir to fully dissolve sodium indigo disulfonate, obtain sodium indigo disulfonate hydrosol, and the molar concentration of sodium indigo disulfonate in the hydrosol is 0.0050 mol / L;

[0042]B. Preparation of the reaction mixture: take 180ml of the hydrosol obtained in step a, then add 1.38ml of pyrrole, and then magnetically stir for 20min in an ice bath until the temperature of the mixture drops to 3°C to obtain the reaction mixture;

[0043] C, the preparation of initiator solution: FeCl 3 ·6H 2 O was added to distilled water and stirred well until the FeCl 3 ·6H 2 O is completely dissolved, and the initiator solution is obtained, in which FeCl 3 The molar concentration is 0.07mol / L;

[0044] D. Polymerization of pyrrole: 20 ml of the initiator solution prepared in step c was added dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com