Method for efficiently and continuously preparing heat-conducting graphite film on large area

A heat-conducting graphite film and graphene technology, applied in coatings, natural rubber coatings, conjugated diene coatings, etc., can solve the problem of poor mechanical properties and thermal conductivity of graphite films, no mention of calendering and process parameters, and impossibility Continuous large-area production and other issues, to achieve the effects of regular grain orientation, ultra-thin thickness, and overcoming high temperature and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

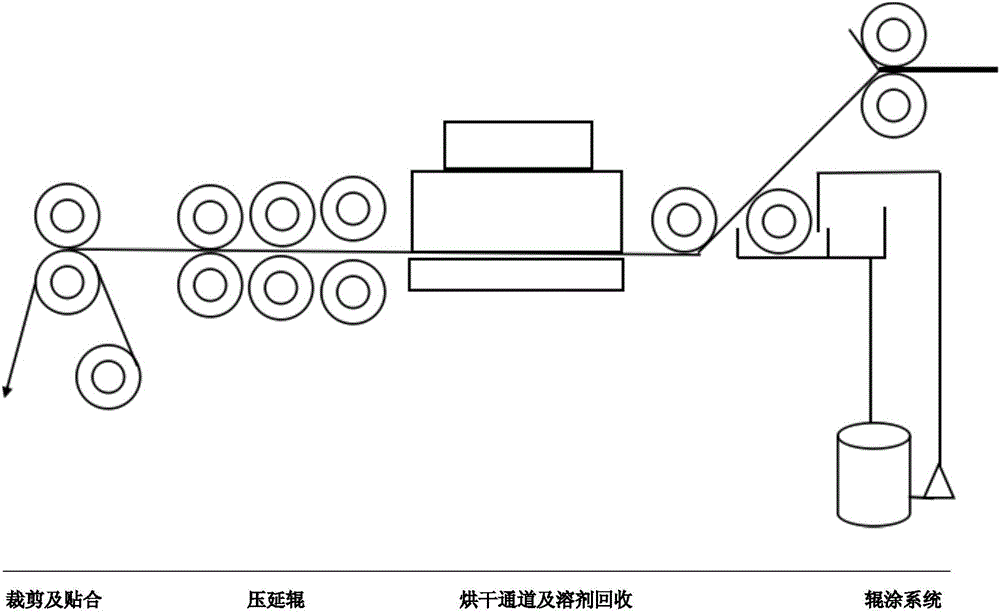

[0033] like figure 1 As shown, first weigh 1 kg of graphene powder (N008-P) with 5-8 layers of graphene, and disperse it into polytetrafluoroethylene emulsion to control the quality of graphene powder and polytetrafluoroethylene The mass ratio of the emulsion solute is 4:1, and it is refined by a refiner, and water can be added in the middle to adjust the viscosity of the slurry, and the viscosity is controlled to 6000mPa·s. Then pour the ground slurry into the low-level storage tank of the roller coating system, adjust the speed of the pressure pump to 50r / min, and adjust the speed of the electric roller coating wheel to 40r / min, so that the surface of the electric roller coating wheel is fully covered in the high-level liquid storage tank. Wetting, sticking the slurry, and then tearing off the single-sided release film to expose the base-loaded film (commercially available) of the adhesive layer is close to the roller coating wheel for roller coating operation. Pass the fil...

Embodiment 2

[0036] First take by weighing the graphene powder (N006-P) that the number of layers of 1kg is 3~5 layers of graphene, it is dispersed in the natural rubber emulsion, controls the mass ratio of graphene powder quality and natural rubber emulsion solute 9: 1. After being refined by a refiner, water can be added in the middle to adjust the viscosity of the slurry, and the viscosity is controlled to 4000mPa·s. Then pour the ground slurry into the low-level storage tank of the roller coating system, adjust the speed of the pressure pump to 60r / min, and adjust the speed of the electric roller coating wheel to 60r / min, so that the surface of the electric roller coating wheel is fully infiltrated in the high-level liquid storage tank , stick the size, and then tear off the single-sided release film to expose the base-loaded film (commercially available) of the adhesive layer close to the roller coating wheel for roller coating operation. Pass the film loaded with slurry through a hot...

Embodiment 3

[0038] First take by weighing the graphene powder (N002-PDR) of 1kg single-layer graphene, it is dispersed in the polyvinyl alcohol aqueous solution, the mass ratio of control graphene powder quality and polyvinyl alcohol aqueous solution solute 9.5:1, through The pulp is refined by a refiner, and water can be added in the middle to adjust the viscosity of the slurry, and the viscosity is controlled to 3000mPa·s. Then pour the ground slurry into the low-level storage tank of the roller coating system, adjust the speed of the pressure pump to 40r / min, and adjust the speed of the electric roller coating wheel to 80r / min, so that the surface of the electric roller coating wheel is fully infiltrated in the high-level liquid storage tank , stick the size, and then tear off the single-sided release film to expose the base-loaded film (commercially available) of the adhesive layer close to the roller coating wheel for roller coating operation. Pass the film loaded with slurry through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com