Chemical vapor deposition (CVD) method adopting microwave heating mode

A technology of chemical vapor deposition and microwave heating, which is applied in the field of chemical vapor deposition (CVD), can solve the problems of slow heating rate, high energy consumption, and low production efficiency, and achieve the effects of increased efficiency, uniform film thickness, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Select high-purity graphite as the substrate, process it into a cylindrical substrate, hang it in the reactor chamber, turn on the rotary vane pump, and vacuum the reaction chamber to 0.1 Torr;

[0027] (2) Turn on the microwave heating system, with an initial power of 6kW, and heat at a heating rate of 10°C / min to a temperature of 1100°C;

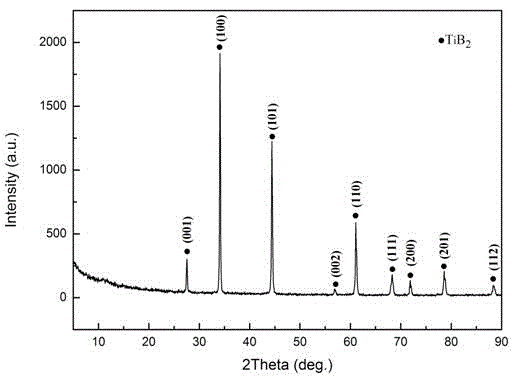

[0028] (3) After heating and volatilizing titanium tetrachloride and boron chloride, they are mixed with a heating belt and hydrogen, and then input into the reaction chamber together, in which TiCl 4 The dosage is 450g / h, BCl 3 The dosage is 1000g / h, the flow rate of hydrogen is 0.7m 3 / h, the aeration time is 2 hours, that is, the deposition time is 2 hours. During this process, the temperature of the substrate is kept at 1100 ° C. The reaction gas and unreacted gas are pumped out by a vacuum pump, and after passing through the iron filings absorption part, they pass through the 0.2mol / L of NaOH solution is sprayed and wash...

Embodiment 2

[0031] (1) Choose silicon carbide as the substrate, process it into a sheet-like substrate, hang it in the reactor chamber, turn on the rotary vane pump, and vacuum the reaction chamber to 1 Torr;

[0032] (2) Turn on the microwave heating system, with an initial power of 4.5kW, and heat at a heating rate of 5°C / min until the temperature is 1000°C;

[0033] (3) After heating and volatilizing titanium tetrachloride and boron chloride, they are mixed with a heating belt and hydrogen, and then input into the reaction chamber together, in which TiCl 4 The dosage is 300g / h, BCl 3 The dosage is 600g / h, the flow rate of hydrogen is 0.4m 3 / h, the aeration time is 1 hour, that is, the deposition time is 1 hour. During this process, the temperature of the substrate is kept at 1000 ° C. The reaction gas and unreacted gas are pumped out by a vacuum pump, and after passing through the iron filings absorption part, they pass through 0.01mol / L of NaOH solution is sprayed and washed for c...

Embodiment 3

[0036] (1) Choose graphite composite material as the matrix, process it into a cylindrical matrix, hang it in the reactor cavity, turn on the rotary vane pump, and evacuate the reaction cavity to 0.5 Torr;

[0037] (2) Turn on the microwave heating system, with an initial power of 9kW, and heat at a heating rate of 12°C / min to a temperature of 500°C;

[0038] (3) After heating and volatilizing titanium tetrachloride and boron chloride, they are mixed with a heating belt and hydrogen, and then input into the reaction chamber together, in which TiCl 4 The dosage is 400g / h, BCl 3 The dosage is 900g / h, the flow rate of hydrogen is 0.5m 3 / h, the aeration time is 5 hours, that is, the deposition time is 5 hours. During this process, the temperature of the substrate is kept at 500 ° C. The reaction gas and unreacted gas are pumped out by a vacuum pump, and after passing through the iron filings absorption part, they pass through 1mol / L The NaOH solution is sprayed and washed for c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com