Preparation process for lead-free front electrode silver paste of solar cell

A technology for solar cells and front electrodes, applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve poor wettability, difficulty in achieving the performance of lead-containing glass powder, high glass transition temperature, etc. problem, to achieve the effect of good wettability, good contact and low glass viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

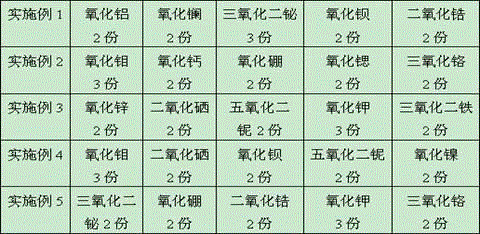

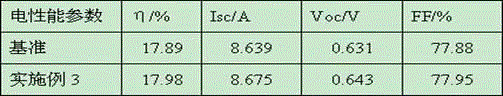

[0020] Embodiments 1 to 5: A preparation process for a lead-free front electrode silver paste for solar cells, the front silver conductive paste is composed of the following components by weight, as shown in Table 1:

[0021] Table 1

[0022]

[0023] The oxide additive is composed of the following components by weight, as shown in Table 2:

[0024] Table 2

[0025]

[0026] The above-mentioned organic solvent is at least one of terpineol, butyl carbitol, butyl carbitol acetate and propylene glycol methyl ether acetate.

[0027] The above-mentioned silver conductive phase is 0.5-10 micron silver powder.

[0028] The preparation process of the above-mentioned lead-free positive electrode silver paste for solar cells comprises the following steps:

[0029] Step 1. Add 0.3~0.6 parts of sodium oxide, 0.7~1.3 parts of tellurium dioxide, 0.55~1 part of tungsten trioxide, 0.25~0.5 parts of oxide additives, 0.08~0.2 parts of silicon dioxide, and 0.04~0.1 parts of lithium oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com